Extended Brake Lines for Lifted Trucks: A Comprehensive Guide to Safety and Performance

Extended Brake Lines for Lifted Trucks: A Comprehensive Guide to Safety and Performance

Lifting a truck is a popular modification that enhances its aesthetic appeal, increases ground clearance, and improves off-road capability. However, this seemingly straightforward upgrade introduces a cascade of considerations for various vehicle components, none more critical than the braking system. Among these, the often-overlooked necessity of extended brake lines for lifted trucks stands paramount for ensuring safety, maintaining performance, and preventing costly damage.

This comprehensive guide will delve into every facet of extended brake lines, from their fundamental importance to choosing, installing, and maintaining them. Whether you’re a seasoned off-roader or contemplating your first lift, understanding this crucial upgrade is non-negotiable for a safe and enjoyable driving experience.

What Are Extended Brake Lines and Why Are They Crucial for Lifted Trucks?

At its core, a brake line is a conduit that transmits hydraulic pressure from the master cylinder to the brake calipers or wheel cylinders, activating the braking mechanism. Stock brake lines are engineered for the original suspension travel and ride height of your truck.

When a truck is lifted, its suspension geometry changes significantly. The distance between the brake caliper (mounted on the axle) and the frame-mounted brake line junctions increases. More critically, the suspension’s ability to articulate – to move up and down through its full range of travel – is also extended. If the original, shorter brake lines remain in place, they will be stretched taut, especially during extreme suspension droop (when the wheel hangs furthest down, such as when crossing a ditch or during aggressive off-roading).

This stretching puts immense strain on the brake lines, leading to several dangerous scenarios:

- Line Rupture: The most severe outcome, where the line bursts under tension, resulting in an immediate and catastrophic loss of braking fluid and braking power.

- Leakage: Micro-fissures or stress cracks can develop, leading to slow leaks, reduced brake fluid pressure, and a spongy brake pedal.

- Abrasion and Wear: Stretched lines are more susceptible to rubbing against suspension components or the chassis, leading to premature wear and potential failure.

- Restricted Suspension Travel: In some cases, severely stretched lines can actually limit the full articulation of your suspension, hindering off-road performance and potentially damaging other components.

Extended brake lines for lifted trucks are simply longer versions of their stock counterparts, designed to accommodate the increased distance and greater suspension articulation afforded by a lift kit. They restore the necessary slack, allowing the suspension to move freely without putting undue stress on the braking system, thereby preserving safety and functionality.

The Essential Role of Extended Brake Lines in Lifted Vehicles

The importance of this modification cannot be overstated. It’s not merely an upgrade; it’s a safety imperative that directly impacts your ability to stop your vehicle effectively.

- Preventing Catastrophic Failure: The primary benefit is preventing brake line failure. A ruptured brake line means you’ve lost hydraulic pressure to at least two wheels, and potentially all four, depending on the brake system’s design. This is an extremely dangerous situation that can lead to severe accidents.

- Maintaining Braking Performance: Even if a line doesn’t rupture, constant stretching can compromise its integrity, leading to a spongy pedal feel or reduced braking efficiency. Extended lines ensure consistent hydraulic pressure delivery.

- Ensuring Full Suspension Articulation: For off-road enthusiasts, a lifted truck’s advantage lies in its enhanced articulation. Extended brake lines ensure that the braking system doesn’t become the limiting factor for your suspension’s movement, allowing your wheels to drop fully into obstacles and maintain traction.

- Protecting Other Components: By preventing excessive tension, extended lines also protect the fittings and mounting points on both the calipers and the frame from stress-related damage.

Understanding Brake Line Types and Materials

When considering extended brake lines for lifted trucks, you’ll primarily encounter two types:

-

Rubber Brake Lines:

- Description: Similar to your factory lines, these consist of a synthetic rubber hose reinforced with internal braiding.

- Pros: Generally more affordable, flexible, and good at absorbing vibrations.

- Cons: Prone to expansion under high pressure (leading to a slightly spongy pedal), can degrade over time due to UV exposure, heat, and contaminants, and are more susceptible to stretching and abrasion when not properly sized for a lift.

- Best For: Budget-conscious replacements for moderate lifts, where extreme off-roading isn’t the primary use.

-

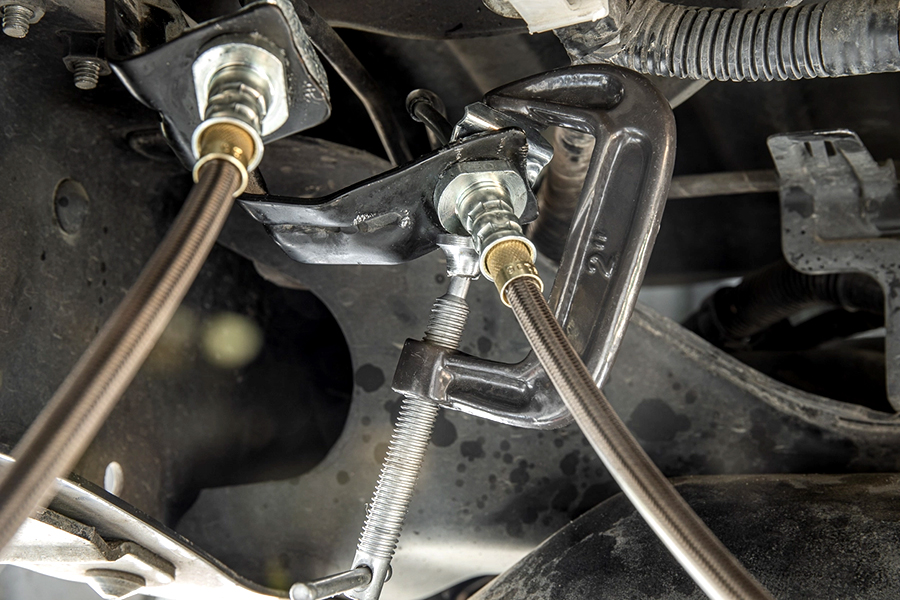

Stainless Steel Braided Brake Lines:

- Description: These feature a PTFE (Teflon) inner hose, reinforced with a tightly woven stainless steel braid, and often covered with a protective PVC or clear plastic coating.

- Pros: Significantly less expansion under pressure, leading to a firmer, more consistent brake pedal feel. Highly resistant to abrasion, corrosion, and stretching. Offers superior durability and performance, especially under demanding conditions.

- Cons: More expensive than rubber lines.

- Best For: Any lifted truck, especially those used for serious off-roading, towing, or performance driving, where maximum durability and braking consistency are desired. They are considered a significant upgrade over rubber lines.

Regardless of the material, always ensure that any extended brake lines you purchase are DOT (Department of Transportation) approved. This certification guarantees that the lines meet rigorous safety and quality standards.

Choosing the Right Extended Brake Lines for Your Lift

Selecting the correct extended brake lines for lifted trucks involves several critical considerations:

-

Determine the Required Length: This is the most crucial step.

- Measurement Method: Jack up your truck and remove the wheels. Support the frame securely on jack stands. Unbolt your shocks and carefully allow the axle to droop to its absolute maximum (full articulation). Measure the distance from your brake caliper’s connection point to the frame-mounted hard line connection point, ensuring enough slack for full steering lock and articulation without any tension. Add a few inches for safety and proper routing.

- Lift Kit Specifics: Many reputable lift kit manufacturers offer specific extended brake lines designed to match their lift heights. This is often the safest and easiest route.

- Rule of Thumb: Generally, for a 2-3 inch lift, an additional 2-4 inches of brake line length might suffice. For 4-6 inch lifts, 4-8 inches of additional length is common. Always measure to be sure.

- Caution: Too long can be problematic too, leading to rubbing, kinking, or getting snagged. Aim for "just right."

-

Material Choice: As discussed, stainless steel braided lines offer superior performance and durability, making them the preferred choice for most lifted applications.

-

Fittings and Connections: Ensure the fittings on the extended lines match your truck’s master cylinder, calipers, and any intermediate hard lines. Most reputable brands will specify compatibility. Double-check the thread type and size.

-

DOT Compliance: Verify that the brake lines are DOT-approved. This is non-negotiable for safety and legality.

-

Brand Reputation: Stick with established and trusted brands known for quality braking components.

Installation Guide: A Step-by-Step Overview

While professional installation is always recommended for safety-critical components like brakes, understanding the process can be helpful.

- Safety First: Park on a level surface, engage the parking brake, and place wheel chocks. Loosen lug nuts. Jack up the truck and support it securely on jack stands. Remove the wheels.

- Gather Tools: You’ll need flare nut wrenches (to avoid stripping brake line fittings), a drain pan, brake fluid, a brake bleeder kit (or a friend), and possibly a torque wrench.

- Prepare for Fluid Loss: Place a drain pan under each caliper as you work.

- Remove Old Lines: Carefully unbolt the old brake lines from the caliper and the frame-mounted hard line. Be prepared for brake fluid to drip.

- Install New Lines: Attach the new extended lines, ensuring proper routing. They should have enough slack but not be so long that they can get snagged, kinked, or rub against other components during full suspension travel or steering lock. Secure them using any provided clips or mounting points.

- Bleed the Brakes: This is the most critical step. Air introduced into the system during line replacement must be removed. Start with the wheel furthest from the master cylinder and work your way closer. Follow the specific bleeding procedure for your vehicle (usually involving pumping the pedal and opening/closing bleeder screws). Ensure the master cylinder reservoir never runs dry.

- Inspect for Leaks: After bleeding, visually inspect all connections for any signs of brake fluid leakage.

- Test Drive: Drive slowly in a safe area, testing the brakes at low speeds to ensure proper function and a firm pedal. Check for leaks again after the test drive.

Disclaimer: If you are not confident in your mechanical abilities, especially with brake systems, always seek professional installation. Your safety depends on it.

Important Considerations and Tips

- Pre-Installation Check: Before installing new lines, inspect your calipers, rotors, and pads. This is a good time for a complete brake system health check.

- Proper Routing is Key: Take your time to route the new lines to prevent kinks, rubbing, or snagging. They should have a gentle curve at all points of suspension travel and steering.

- Secure Lines: Use OEM-style clips or zip ties (rated for automotive use) to secure the lines away from moving parts, sharp edges, and exhaust heat.

- Use Fresh Brake Fluid: Always use new, clean brake fluid of the correct DOT rating for your vehicle when bleeding. Never reuse old fluid.

- Bleeding Technique: A two-person bleeding method (one pumping the pedal, one at the bleeder screw) is common. Pressure bleeders or vacuum bleeders can also be used for a more efficient process.

- Check ABS/ESP Compatibility: Most extended brake lines are designed to work seamlessly with modern ABS and Electronic Stability Program (ESP) systems, but it’s always wise to confirm with the manufacturer.

- Regular Inspection: Even after installation, regularly inspect your brake lines for any signs of wear, damage, or leaks, especially after off-road excursions.

Potential Challenges and Solutions

- Stripped Fittings: Old, rusted fittings can be difficult to remove without stripping. Use flare nut wrenches, which grip more surfaces than standard open-end wrenches. Apply penetrating oil beforehand.

- Air in the System: The most common post-installation issue. Thorough, systematic bleeding is the solution. If a spongy pedal persists, you may need a professional shop with specialized bleeding equipment (e.g., for ABS modules).

- Incorrect Length: If the lines are too short, they’ll stretch. Too long, and they might rub or snag. Measure meticulously, or purchase lines specifically designed for your lift kit.

- Leaky Connections: Ensure all fittings are tightened to the manufacturer’s specifications (use a torque wrench). Avoid over-tightening, which can strip threads. Check for cross-threading during installation.

Price Table: Extended Brake Lines for Lifted Trucks

| Item/Type | Description | Price Range (USD) |

|---|---|---|

| Front Extended Rubber Brake Line | OEM-style, single front line, for moderate lifts | $40 – $80 |

| Rear Extended Rubber Brake Line | OEM-style, single rear line, for moderate lifts | $40 – $80 |

| Complete Set Extended Rubber Brake Lines | Front & Rear (2-4 lines total), for moderate lifts | $80 – $150 |

| Front Extended Stainless Steel Braided Brake Line | Performance upgrade, single front line, superior durability | $80 – $150 |

| Rear Extended Stainless Steel Braided Brake Line | Performance upgrade, single rear line, superior durability | $80 – $150 |

| Complete Set Extended Stainless Steel Braided Brake Lines | Front & Rear (2-4 lines total), ultimate performance and durability | $150 – $300 |

| Installation Cost (Professional) | Labor only, varies by region and shop; does not include parts | $100 – $300+ |

Note: Prices are estimates and can vary significantly based on vehicle make/model, brand, retailer, and regional labor rates.

Frequently Asked Questions (FAQ) About Extended Brake Lines for Lifted Trucks

Q1: Do I really need extended brake lines for a small lift (e.g., 2 inches)?

A1: While a 2-inch lift might seem minimal, it can still put undue stress on stock brake lines, especially during full suspension droop or aggressive off-roading. It’s always a good idea to measure and confirm. For safety, most experts recommend extended lines for any lift over 1.5-2 inches.

Q2: How much longer should my extended brake lines be?

A2: The best way to determine this is by measuring at full suspension droop and full steering lock. Generally, you want enough slack so the lines are not taut, but not so much that they can get snagged or rub. Many lift kit manufacturers will specify the appropriate length for their kits.

Q3: Can I install extended brake lines myself?

A3: If you have experience working on brake systems, possess the correct tools, and understand the critical process of bleeding brakes, it is possible. However, due to the safety-critical nature of brakes, professional installation is highly recommended if you have any doubts.

Q4: What’s the difference between rubber and stainless steel braided brake lines?

A4: Rubber lines are more economical and flexible but can expand under pressure, leading to a softer pedal. Stainless steel braided lines have a PTFE inner hose with a steel braid, offering minimal expansion (firmer pedal), superior durability, and resistance to abrasion and corrosion.

Q5: Are all extended brake lines DOT approved?

A5: No. Always verify that any brake lines you purchase are DOT (Department of Transportation) approved. This ensures they meet federal safety and quality standards. Avoid lines that do not have this certification.

Q6: Will extended brake lines affect my ABS or ESP system?

A6: Generally, no. Extended brake lines simply replace the length of the hydraulic line and do not interfere with the electronic signals or sensors of ABS or ESP systems. As long as the system is properly bled and free of air, these systems should function normally.

Q7: How often should I inspect my brake lines?

A7: You should inspect your brake lines as part of your regular vehicle maintenance, typically every oil change or at least once a year. Pay extra attention after off-road trips or if you notice any changes in braking performance. Look for cracks, bulges, leaks, or signs of rubbing.

Conclusion

Upgrading to extended brake lines for lifted trucks is not merely an accessory; it is a fundamental safety and performance enhancement. Neglecting this crucial component can lead to dangerous situations, compromised braking ability, and costly repairs. By understanding their importance, choosing the correct type and length, and ensuring proper installation, you safeguard your investment and, most importantly, your life and the lives of those around you.

Prioritize safety over shortcuts. When you lift your truck, ensure its braking system is adequately prepared for the new demands. This simple yet vital modification provides peace of mind, allowing you to confidently enjoy the enhanced capabilities and aesthetics of your lifted vehicle, whether on the road or tackling challenging off-road trails.