Dual Battery Setup for a Plow Truck : Ultimate Guide

Dual Battery Setup for a Plow Truck – When preparing a plow truck for winter duty, one essential upgrade is setting up a dual battery system. A single battery often struggles under the load of auxiliary equipment like plow systems, additional lighting, and other electronics that demand significant power.

A dual battery setup ensures your truck has the electrical power to run your plow and accessories without draining the primary battery, leaving you stranded. Below, we explore the best methods for installing a dual battery system in your plow truck to ensure optimal performance during the harshest winter conditions.

Why You Need a Dual Battery Setup for Your Plow Truck

A single battery in a plow truck can quickly become overloaded by the high electrical demands of the snowplow’s hydraulic system, lights, and heater fans. These accessories draw considerable power, especially when the plow is in constant use over extended periods. In cold weather, when battery performance naturally declines, this situation can lead to a dead battery if you rely solely on one.

A dual battery setup offers a solution by separating the load between two batteries: one dedicated to starting the vehicle and another for running accessories. This separation reduces wear on the primary battery and ensures your truck remains operational, even during the most demanding plowing sessions.

Components of a Dual Battery Setup

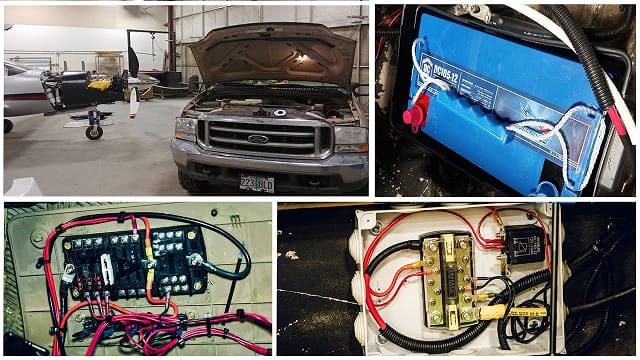

To create a successful dual battery setup for your plow truck, you’ll need the following essential components:

- Second Battery: Preferably a deep-cycle battery capable of withstanding long periods of discharge, as it will provide power to auxiliary systems.

- Battery Isolator: A device that keeps the batteries electrically separate, ensuring that the starting battery is reserved exclusively for engine cranking while the secondary battery powers the accessories.

- Heavy-Duty Wiring: High-quality wiring to connect the batteries and plow systems, ensuring maximum power flow.

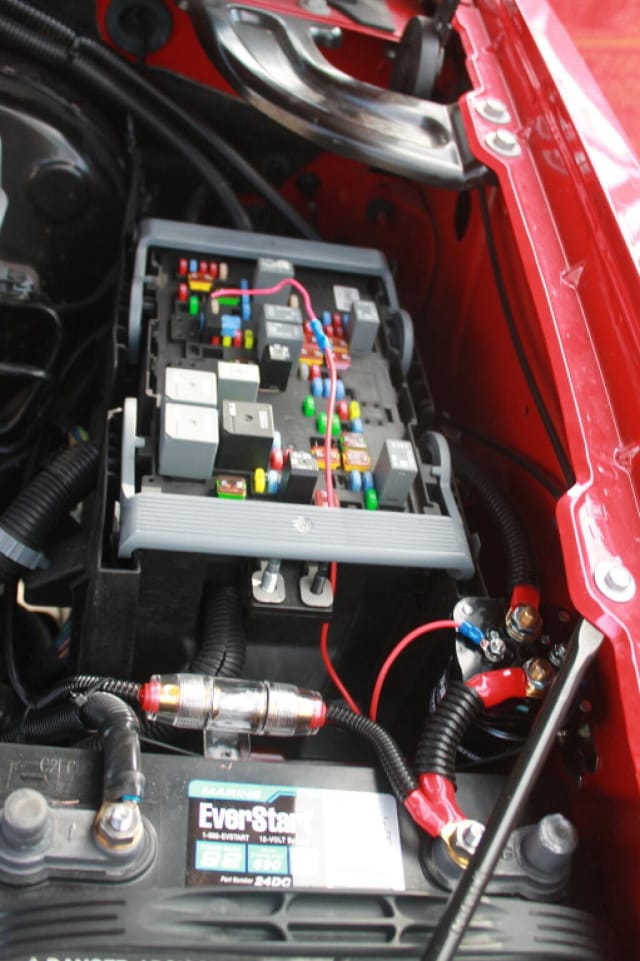

- Fuse Blocks: For protecting the system from electrical overloads and shorts.

- Mounting Brackets: Custom brackets or trays to secure the second battery inside the engine compartment or in another location within the truck.

Step-by-Step Installation Guide for a Dual Battery Setup

1. Choose the Right Location for the Second Battery

Selecting an ideal location for the second battery is crucial. Most plow trucks have ample space in the engine compartment or behind the cab. Ensure the second battery is securely mounted to prevent damage from vibrations. If space in the engine bay is limited, you may need to install the second battery in the truck bed or behind the rear seats, ensuring it’s shielded from moisture and debris.

2. Install the Battery Isolator

A battery isolator is essential for preventing your truck’s starting battery from draining. By keeping the two batteries electrically separate, the isolator ensures that when the engine is off, only the secondary battery powers the accessories. There are different types of battery isolators available, such as solenoid-based or solid-state types. Install the isolator near the batteries and connect it to both using heavy-duty cables.

3. Connect the Wiring

Next, route heavy-gauge wiring from the alternator to both batteries and connect them through the battery isolator. This ensures that both batteries receive a charge while the truck is running. It’s important to use appropriately sized cables, as thin wiring can overheat under high loads. Ensure that all connections are tight and free from corrosion for maximum efficiency.

4. Install Fuses and Circuit Breakers

Adding fuses and circuit breakers is a critical step in protecting your electrical system from shorts or overloads. Place a fuse block between the battery and the auxiliary systems like the plow and lighting. This will prevent excessive current from damaging the system or causing a fire.

5. Mount the Second Battery

Once the wiring and fuses are in place, mount the second battery using heavy-duty brackets. Ensure the battery is secure and positioned in a way that makes it easy to access for maintenance and inspection.

6. Test the System

Once everything is connected, it’s time to test the dual battery system. Start the truck and monitor the voltage of both batteries. The starting battery should only power the engine, while the second battery powers the plow and other accessories. Check all connections for warmth or looseness, and verify that the isolator is working correctly by ensuring that the secondary battery isn’t draining the primary battery when the truck is off.

Best Practices for Maintaining Your Dual Battery System

Now that your plow truck is equipped with a dual battery setup, proper maintenance is key to ensuring its longevity. Follow these tips to keep your system in optimal condition:

- Regularly Check Battery Health: Batteries lose efficiency over time, especially in cold weather. Perform regular checks to ensure both batteries are holding a charge.

- Inspect Wiring for Corrosion: Winter conditions can cause wiring to corrode quickly. Inspect connections and wiring for any signs of corrosion, and apply dielectric grease to protect exposed metal.

- Monitor Charging Levels: Use a battery monitor to track the charge status of both batteries. This will help you catch potential problems before they lead to a dead battery.

- Avoid Overloading the System: While a dual battery setup provides more power, it’s still essential to avoid overloading the system with too many accessories. Prioritize essential equipment and consider adding additional batteries if needed for heavy-duty setups.

Benefits of a Dual Battery Setup

Investing in a dual battery setup for your plow truck comes with numerous benefits, making it a must-have for anyone relying on their vehicle for snow removal:

- Increased Reliability: You no longer have to worry about your truck failing to start due to a drained battery after running lights, heaters, or the plow for extended periods.

- Extended Battery Life: By distributing the electrical load between two batteries, you reduce the strain on each, increasing their longevity.

- More Efficient Power Usage: Separating the battery system allows you to use power more efficiently, especially when using high-demand equipment like a plow or auxiliary lighting.

- Protection Against Battery Drain: With a battery isolator, you can ensure that your starting battery remains fully charged and ready for engine use, even when the auxiliary battery is depleted.

Conclusion

A dual battery setup for your plow truck ensures that you have the reliable power needed to handle the demands of snowplowing, lighting, and other heavy-duty tasks during winter months. By following the steps outlined above, you can install an efficient dual battery system that will keep your plow truck running smoothly and your business operational, no matter how harsh the weather conditions.