How to Wire Plow Truck Lights Effectively

How to Wire Plow Truck Lights Effectively: Proper wiring is crucial for ensuring that plow truck lights function efficiently and reliably. Effective wiring not only ensures optimal performance but also contributes to the overall safety and longevity of your lighting system. This guide provides a detailed overview of how to wire plow truck lights effectively, covering everything from planning and preparation to installation and testing.

1. Planning Your Wiring Setup

Assess Your Lighting Needs

Before you start wiring, it’s important to assess the lighting requirements for your plow truck:

- Types of Lights: Determine the types of lights you’ll be installing, such as headlights, strobe lights, auxiliary lights, or work lights.

- Power Requirements: Check the power requirements for each type of light to ensure your truck’s electrical system can handle the load.

Gather the Necessary Tools and Materials

To wire your plow truck lights effectively, you will need the following tools and materials:

- Wiring Harness: For connecting lights to the truck’s electrical system.

- Fuse Holder: To protect the wiring and lights from power surges.

- Electrical Tape and Wire Loom: For insulating and protecting wires.

- Crimp Connectors: For making secure connections.

- Relay: To control the power supply to the lights.

- Wire Strippers and Crimping Tool: For preparing and connecting wires.

- Screwdrivers and Mounting Hardware: For installing the lights.

2. Preparing the Wiring

Disconnect the Battery

Before starting any electrical work, always disconnect the truck’s battery to prevent any accidental shorts or electrical shocks.

Plan the Wiring Route

Determine the best route for the wiring to avoid interference with moving parts and to keep the installation neat and secure:

- Avoid Heat Sources: Keep wires away from engine components or exhaust pipes that could cause damage.

- Secure Routing: Use a wire loom or cable ties to secure wires along the planned route.

Prepare Wires and Connectors

Prepare the wires and connectors for installation:

- Strip the Wires: Use wire strippers to remove a small section of insulation from the ends of the wires.

- Attach Connectors: Use crimping tools to attach crimp connectors to the stripped wire ends, ensuring a secure connection.

3. Installing the Wiring

Connect the Lights

Follow these steps to connect the lights:

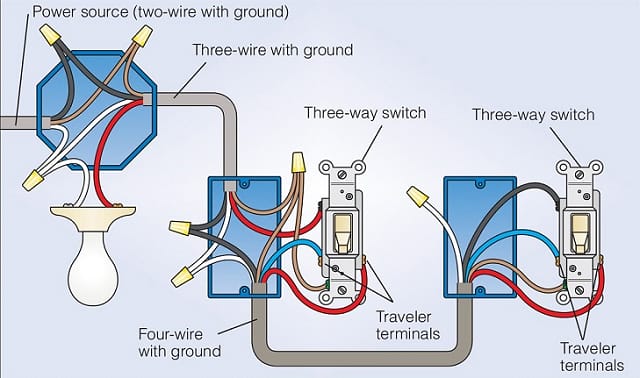

- Connect to the Fuse Box: Run the wiring harness from the light locations to the truck’s fuse box. Ensure that each light is connected to the appropriate fuse to protect against electrical surges.

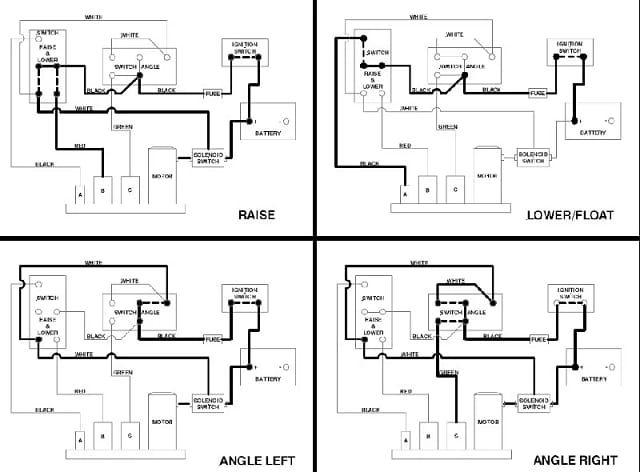

- Wire the Relay: Install a relay to control the power supply to the lights. Connect the relay to the fuse box and ensure that it is properly grounded.

- Connect the Light Wires: Attach the wires from the lights to the wiring harness, ensuring that the positive and negative connections are correctly matched.

Secure the Wiring

Ensure that all wiring is securely fastened:

- Use Cable Ties: Secure the wiring along the planned route with cable ties to prevent movement and abrasion.

- Protect with Wire Loom: Cover wires with a wire loom or electrical tape to provide additional protection against wear and tear.

Mount the Lights

Install the lights in their designated locations:

- Positioning: Mount the lights securely using the provided brackets or hardware, ensuring they are aimed correctly for optimal performance.

- Check Alignment: Verify that the lights are aligned properly and adjust as needed.

4. Testing and Troubleshooting

Reconnect the Battery

Once the wiring is complete and everything is securely installed, reconnect the truck’s battery.

Test the Lights

Turn on the lights and test each one to ensure proper operation:

- Check Functionality: Verify that all lights are working correctly and that there are no flickering or dim spots.

- Test Patterns: For strobe or flashing lights, check that all flash patterns are functioning as expected.

Troubleshoot Issues

If any issues arise, troubleshoot them as follows:

- Check Connections: Ensure all connections are secure and properly insulated.

- Inspect Wiring: Look for any signs of damage or wear in the wiring and make necessary repairs.

- Verify Power Supply: Ensure that the lights are receiving adequate power and that the fuse and relay are functioning correctly.

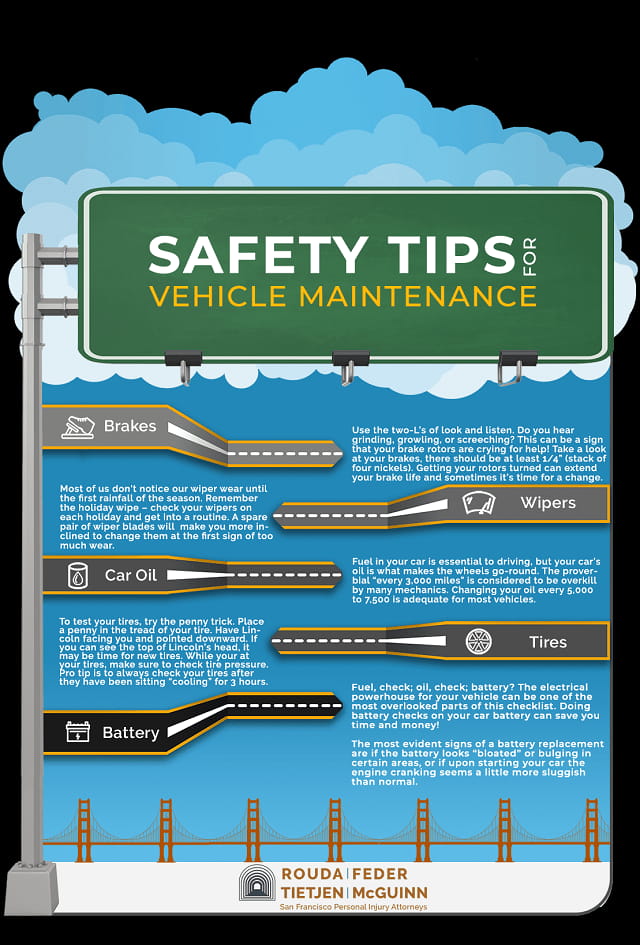

5. Maintenance and Safety Tips

Regular Inspections

Perform regular inspections of your wiring and lights to ensure continued performance:

- Check for Wear: Inspect wiring for signs of abrasion or damage and replace as needed.

- Test Functionality: Periodically test the lights to ensure they are operating correctly.

Follow Safety Guidelines

Adhere to safety guidelines to prevent electrical hazards:

- Avoid Overloading: Ensure that the electrical system is not overloaded by the additional lights.

- Use Proper Components: Always use high-quality components designed for automotive use.

Conclusion

Wiring your plow truck lights effectively is essential for ensuring optimal performance and safety. By following the steps outlined in this guide, you can achieve a reliable and well-organized lighting system that enhances visibility and helps you operate your plow truck safely in challenging conditions.