ATV Ramps for Lifted Trucks: The Ultimate Guide to Safe Loading

ATV Ramps for Lifted Trucks: The Ultimate Guide to Safe Loading

Transporting an All-Terrain Vehicle (ATV) is an integral part of the off-road experience, allowing enthusiasts to explore diverse terrains far from home. While standard trucks offer a relatively straightforward loading process, the rise of lifted trucks introduces a unique set of challenges. ATV ramps for lifted trucks are not merely accessories; they are essential safety equipment designed to bridge the increased height difference between a lifted truck bed and the ground, ensuring a secure and efficient loading and unloading experience. This comprehensive guide will delve into every aspect of selecting, using, and maintaining these specialized ramps, transforming a potentially hazardous task into a smooth operation.

Why Standard Ramps Don’t Cut It for Lifted Trucks

The primary issue with using standard ATV ramps on a lifted truck is the dramatically increased loading angle. A standard truck bed might be around 30 inches high, whereas a lifted truck can easily reach 40-50 inches or more. Using short, standard ramps on a lifted truck creates an excessively steep incline, leading to several critical problems:

- High-Centering Risk: The ATV’s undercarriage can scrape or get stuck on the tailgate or the top of the ramps, causing damage to both the ATV and the truck.

- Loss of Traction: A steep angle makes it harder for the ATV’s tires to maintain grip, especially in wet or muddy conditions, increasing the risk of slipping off the ramps.

- Instability: Shorter ramps are inherently less stable at steep angles, making them more prone to shifting or collapsing under the ATV’s weight.

- Reduced Visibility: The extreme incline can obstruct the rider’s view, making precise maneuvering difficult and dangerous.

- Mechanical Strain: Forcing an ATV up a steep ramp puts undue stress on its drivetrain and suspension.

These risks highlight why investing in ramps specifically designed for the elevated stature of lifted trucks is not just a convenience, but a critical safety measure.

Key Features of ATV Ramps for Lifted Trucks

Specialized ATV ramps for lifted trucks incorporate features engineered to overcome the challenges posed by increased bed height. Understanding these features is crucial for making an informed purchase.

Length: The Foremost Consideration

The most critical feature for lifted truck ramps is their length. Longer ramps significantly reduce the loading angle, making the incline less steep and safer. A good rule of thumb is to aim for a loading angle between 15 and 20 degrees for ATVs. To calculate the approximate required ramp length, you can use a simple formula: divide your truck bed height (in inches) by the sine of your desired angle (e.g., sin(15°) ≈ 0.2588, sin(20°) ≈ 0.3420). For a 45-inch high truck bed, a 15-degree angle would require ramps over 170 inches (14 feet) long, while a 20-degree angle would need over 130 inches (11 feet). Most ramps for lifted trucks range from 8 to 12 feet, with some heavy-duty options extending further.

Width: Stability and Accommodation

Ramps should be wide enough to comfortably accommodate your ATV’s tires, providing ample room for minor steering corrections without risking a wheel slipping off the side. Most ATV ramps are 10-14 inches wide, but for wider ATVs or UTVs, wider or multi-panel ramp systems are available.

Weight Capacity: Exceeding Expectations

Always choose ramps with a combined weight capacity that significantly exceeds the total weight of your ATV, rider, and any gear. It’s advisable to have a buffer of at least 20-30% above your maximum expected load. A typical ATV weighs between 500-800 lbs, so ramps with a 1500-2500 lb capacity are common.

Material: Durability vs. Portability

- Aluminum: The most popular choice due to its lightweight nature, excellent strength-to-weight ratio, and corrosion resistance. Aluminum ramps are easy to handle and store.

- Steel: Stronger and often more affordable than aluminum, but significantly heavier and susceptible to rust if not properly coated. Less common for lifted truck applications due to weight.

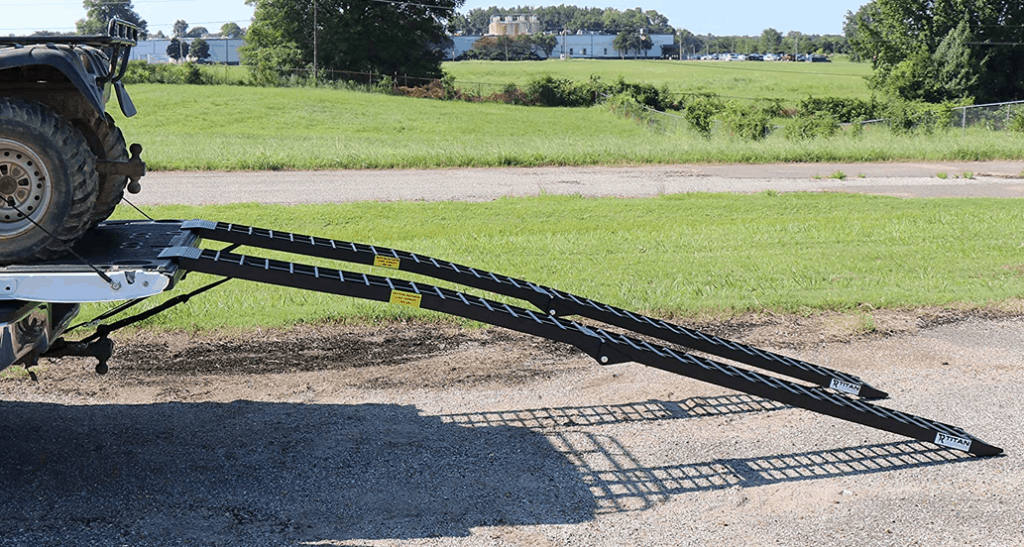

Arch/Curved Design: Preventing High-Centering

Many high-quality ramps for lifted trucks feature an arched or curved design. This curvature provides additional clearance at the break-over point (where the ramp meets the tailgate), effectively preventing the ATV’s undercarriage from scraping or high-centering as it transitions from the ramp to the truck bed.

Traction Surface: Grip in All Conditions

The ramp surface must provide superior traction. Common designs include:

- Rung-style: Individual bars or rungs across the ramp, offering good grip and shedding dirt.

- Expanded Metal: A mesh-like surface that provides excellent traction and allows debris to fall through.

- Raised Tread/Knurled Surface: Integrated patterns designed to grip tires.

Security Straps/Attachment Mechanisms: Non-Negotiable Safety

Ramps must be securely fastened to the truck’s tailgate to prevent them from kicking out or shifting during loading. Most ramps come with heavy-duty cam buckle straps or safety pins that hook into the tailgate’s latch points or stake pockets. Never load an ATV without properly securing the ramps.

Types of ATV Ramps for Lifted Trucks

The market offers various ramp configurations, each with its own advantages:

- Folding Ramps: These are the most common and practical. They fold in half (bi-fold) or into three sections (tri-fold) for compact storage and transport.

- Bi-Fold Ramps: Two sections, good for narrower ATVs, offer a single wide loading surface.

- Tri-Fold Ramps: Three sections, even more compact when folded, often wider when deployed.

- Arched Ramps: Specifically designed with a built-in curve to maximize ground clearance and prevent high-centering, making them ideal for lifted trucks. Many folding ramps also incorporate an arch.

- Heavy-Duty Ramps: Constructed for larger, heavier ATVs or UTVs, these boast higher weight capacities and robust construction, often with wider dimensions.

- Single-Piece Ramps: Less common for lifted trucks due to their unwieldy length, but offer maximum strength and simplicity.

How to Safely Load an ATV onto a Lifted Truck (Step-by-Step Guide)

Safety is paramount when loading an ATV. Follow these steps meticulously:

-

Preparation:

- Level Ground: Park your lifted truck on a firm, level surface.

- Engage Parking Brake: Always set your truck’s parking brake.

- Wheel Chocks: Place wheel chocks behind the rear tires of the truck for added stability.

- Clear Area: Ensure the area around the truck and ramps is clear of obstacles, people, and pets.

- Tailgate Stability: Ensure your tailgate is fully open and can support the weight of the ATV as it transitions. Consider a tailgate reinforcement if loading very heavy ATVs frequently.

-

Ramp Setup:

- Placement: Position the ramps centrally behind the tailgate, ensuring they are evenly spaced for your ATV’s tire width.

- Secure Ramps: Attach the ramps securely to the tailgate using the provided safety straps or pins. Double-check that they are taut and cannot slip.

-

Loading Technique (Choose Wisely):

- Walk-Up Method (Recommended for Safety):

- Start the ATV and engage a low gear (e.g., 4×4 low if applicable).

- Walk alongside the ATV, maintaining a firm grip on the handlebars.

- Apply slow, consistent throttle to guide the ATV up the ramps. Keep your body weight low and slightly behind the ATV.

- Once the front tires are in the truck bed, smoothly guide the rear tires up.

- Disengage the ATV’s engine once it’s fully in the bed.

- Ride-Up Method (Use with Extreme Caution and Experience):

- Wear a helmet and appropriate safety gear.

- Approach the ramps slowly and squarely.

- Maintain a slow, consistent speed. Avoid sudden acceleration or braking.

- Keep your body weight centered or slightly forward, ready to react to changes in angle.

- Once in the truck bed, shut off the engine.

- Walk-Up Method (Recommended for Safety):

-

Securing the ATV:

- Positioning: Center the ATV in the truck bed, ideally with its front tires against the bulkhead.

- Tie-Downs: Use at least four heavy-duty ratchet straps or cam buckle straps.

- Attach two straps to the front of the ATV’s frame or strong suspension components, pulling forward and outward to the truck’s anchor points.

- Attach two more straps to the rear of the ATV, pulling backward and outward.

- Check Tension: Ensure all straps are taut, and the ATV cannot shift. Give it a good shake to test.

-

Unloading:

- Reverse Process: Ensure the ramps are securely attached.

- Engine On: Start the ATV, engage a low gear.

- Slow Descent: Guide the ATV slowly down the ramps, using engine braking and light brake application. Avoid sudden movements.

- Spotter: A spotter is highly recommended for both loading and unloading, especially with lifted trucks.

Important Considerations and Practical Tips

- Accurate Bed Height Measurement: Before buying ramps, precisely measure your truck bed’s height from the ground to the top of the tailgate. This is crucial for selecting the correct ramp length.

- Know Your ATV’s Wet Weight: Always account for the ATV’s weight with a full tank of fuel, accessories, and any gear you typically carry.

- Angle of Incline: While 15-20 degrees is ideal for ATVs, steeper angles might be unavoidable with very high lifts. If the angle is too steep, consider alternative loading methods like a trailer or a dedicated truck bed loading system.

- Ramp Maintenance: Regularly inspect your ramps for cracks, bent rungs, loose fasteners, or damaged traction surfaces. Clean off dirt and debris after each use.

- Proper Storage: Store ramps in a dry place to prevent corrosion. Foldable ramps are easier to store in the truck bed or garage.

- Always Use a Spotter: An extra set of eyes can alert you to potential hazards, guide your maneuvering, and confirm ramp stability.

- Practice Makes Perfect: If you’re new to loading ATVs, especially onto a lifted truck, practice in a safe, open area with no pressure.

- Weather Conditions: Exercise extreme caution in wet, icy, or muddy conditions, as traction will be significantly reduced for both the ATV and the ramps.

Conclusion

Loading an ATV onto a lifted truck presents unique challenges, but with the right equipment and a commitment to safety, it can be a routine and secure process. Investing in specialized ATV ramps for lifted trucks is not just about convenience; it’s about protecting your valuable ATV, your truck, and most importantly, yourself. By understanding the key features, choosing the appropriate type, and diligently following safety protocols, you can confidently transport your ATV to your next adventure, ensuring a smooth start and end to every ride. Prioritize quality, practice safety, and enjoy the freedom your lifted truck and ATV offer.

For more information on selecting the right ramps, you can explore specialized ramp retailers here. (Note: This is a placeholder link, as I cannot create live, functional links.)

Price Table: ATV Ramps for Lifted Trucks

| Ramp Type | Material | Length (Unfolded) | Width (Each) | Capacity (Pair) | Key Features | Price Range (USD) |

|---|---|---|---|---|---|---|

| Folding Arched | Aluminum | 8-10 ft | 11-13 in | 1500-2200 lbs | Arched design, compact fold, safety straps | $180 – $350 |

| Heavy-Duty Arched | Aluminum | 10-12 ft | 12-14 in | 2000-3000 lbs | Enhanced arch, wider, reinforced construction | $300 – $600 |

| Tri-Fold Arched | Aluminum | 7.5-9 ft | 30-45 in | 1800-2500 lbs | Single wide surface, tri-fold for storage, arch | $250 – $450 |

| UTV/ATV Combo | Aluminum | 10-13 ft | 14-16 in | 3000-5000 lbs | Extra wide & long, heavy-duty for UTVs/ATVs | $450 – $800+ |

| Non-Folding Arched | Aluminum | 10-12 ft | 12-14 in | 2000-2800 lbs | Max strength, no hinges, requires more storage | $250 – $500 |

Note: Prices are approximate and can vary based on brand, specific features, and retailer.

Frequently Asked Questions (FAQ) about ATV Ramps for Lifted Trucks

Q1: How long should ATV ramps be for a lifted truck?

A1: The ideal length depends on your truck bed’s height. Generally, for lifted trucks, you’ll need ramps between 8 to 12 feet long to achieve a safe loading angle (15-20 degrees). Measure your truck bed height and use the formula (Height / sin(angle)) to estimate the required length.

Q2: Can I use wooden ramps for my lifted truck?

A2: While technically possible, wooden ramps are generally not recommended, especially for lifted trucks. They are heavy, prone to rot or splintering, offer inconsistent traction, and can fail catastrophically without warning. Aluminum ramps are a much safer and more reliable choice.

Q3: Is it safer to ride my ATV up the ramps or walk it up?

A3: For maximum safety, the "walk-up" method (walking alongside the ATV while guiding it with slow throttle control) is always recommended. Riding up carries a higher risk of injury due to potential loss of control, especially on steep inclines or if the ramps shift.

Q4: How do I prevent the ramps from slipping off the tailgate?

A4: Always use the security straps or pins provided with your ramps. These mechanisms are designed to anchor the ramps firmly to your truck’s tailgate, preventing them from kicking out during loading or unloading. Never attempt to load without securing the ramps.

Q5: What is the ideal loading angle for an ATV onto a lifted truck?

A5: An ideal loading angle for ATVs is typically between 15 and 20 degrees. This angle provides a good balance of traction, clearance, and safety. Steeper angles increase the risk of high-centering, slipping, and loss of control.

Q6: Do I need separate ramps if I also transport a UTV?

A6: UTVs are generally wider and significantly heavier than ATVs. While some heavy-duty ATV ramps might suffice for smaller UTVs, it’s often safer and more practical to invest in dedicated UTV ramps or "UTV/ATV Combo" ramps. These are typically wider, longer, and have a much higher weight capacity. Always check the UTV’s weight against the ramp’s capacity.