Truck Tool Box Lights: Illuminating Your Efficiency and Organization

Imagine this: It’s dusk, you’re on a job site, or perhaps just pulled over on the side of the road, and you need a specific tool from your truck tool box. You fumble around, straining your eyes, using your phone’s flashlight, or worse, striking a match to find that elusive wrench. This common scenario highlights a fundamental problem that many truck owners, tradespeople, and outdoor enthusiasts face: inadequate lighting within their tool boxes.

This is where truck tool box lights become an indispensable asset. Far from a mere luxury, these compact, powerful illumination solutions transform a dark, chaotic cavern into an organized, easily accessible workspace. They are specifically designed to withstand the rugged environments of truck beds, providing crucial visibility when and where you need it most. From preventing lost tools and improving safety to boosting productivity during early mornings, late nights, or in dimly lit conditions, truck tool box lights are a game-changer for anyone who relies on their tools on the go. This comprehensive guide will delve into everything you need to know about these essential accessories, helping you choose, install, and maintain the perfect lighting solution for your truck tool box.

Why You Need Truck Tool Box Lights: Beyond Just Seeing

The benefits of integrating a lighting system into your truck tool box extend far beyond the simple act of seeing. They directly impact efficiency, safety, and the longevity of your tools.

- Enhanced Visibility & Organization: The primary benefit is obvious – clear visibility. No more rummaging or guessing. With proper lighting, every tool, every nut, and every bolt is easily identifiable. This not only saves time but also helps maintain better organization, as you can quickly spot misplaced items or return tools to their designated spots.

- Increased Productivity: Time is money, especially for professionals. Whether you’re a contractor, plumber, electrician, or even just tackling a DIY project, being able to quickly locate the right tool means less downtime and more time spent on the actual task. This is invaluable when working against deadlines or in time-sensitive situations.

- Improved Safety: Working in low light conditions can be hazardous. The risk of cuts, scrapes, or other injuries increases when you can’t clearly see what you’re doing. Proper tool box lighting reduces these risks significantly, allowing for safer handling of sharp tools and heavy equipment. It also prevents tripping over tools or other objects that might be obscurely placed.

- Protection for Your Tools: When you can see your tools clearly, you’re less likely to drop them, bang them together, or mishandle them. This seemingly minor benefit contributes to the longevity of your valuable equipment, reducing wear and tear and the need for premature replacements.

- Versatility in All Conditions: Whether it’s a cloudy day, late at night, in a dimly lit garage, or under the shade of a large vehicle, truck tool box lights ensure you have adequate illumination regardless of external lighting conditions. This makes them invaluable for emergency roadside repairs or early morning starts.

Types of Truck Tool Box Lights: Choosing Your Illumination Style

The market offers a variety of truck tool box lighting solutions, each with its own advantages. Understanding the different types will help you select the best fit for your specific needs and tool box configuration.

- LED Light Strips: These are by far the most popular and versatile option. They consist of a flexible strip embedded with numerous small LED lights, often backed with adhesive for easy installation.

- Pros: Highly customizable lengths, excellent light distribution, low profile, energy-efficient, often waterproof.

- Cons: Requires careful routing of wires (if wired), adhesive might weaken over time in extreme temperatures.

- Puck Lights/Spot Lights: These are small, circular, self-contained lights, typically battery-powered. They offer focused illumination rather than widespread coverage.

- Pros: Easy to install (often magnetic or adhesive), highly portable, can be placed exactly where needed.

- Cons: Limited coverage, requires multiple units for full illumination, battery replacement can be frequent.

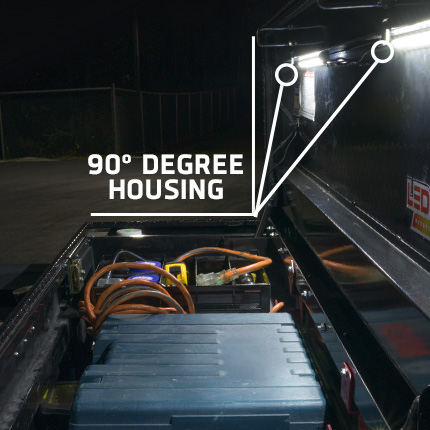

- Under-Lid Lights: Designed to attach directly to the underside of the tool box lid, these lights illuminate the entire box when the lid is open. They can be LED strips or bars.

- Pros: Provides comprehensive lighting, activated automatically when lid opens (if wired with a switch), keeps lights out of the way.

- Cons: Less effective if the box is very deep or has many compartments blocking light.

- Motion-Activated Lights: These lights incorporate a motion sensor, turning on automatically when movement is detected and turning off after a period of inactivity.

- Pros: Hands-free operation, conserves power, convenient.

- Cons: Can be triggered accidentally, may not stay on long enough for extended tasks, typically battery-powered.

- Battery-Powered vs. Wired (12V) Lights:

- Battery-Powered: Offer ultimate portability and ease of installation, no wiring required. Common battery types include AA, AAA, or built-in rechargeable lithium-ion.

- Pros: Simple installation, no truck battery drain.

- Cons: Requires battery replacement/recharging, potential for dimming as batteries drain.

- Wired (12V): Connect directly to your truck’s 12V electrical system.

- Pros: Consistent, powerful illumination, no battery replacement, can be tied to truck’s ignition or a dedicated switch.

- Cons: Requires more complex installation (wiring, fusing), potential for minor truck battery drain if left on.

- Battery-Powered: Offer ultimate portability and ease of installation, no wiring required. Common battery types include AA, AAA, or built-in rechargeable lithium-ion.

Key Features to Look For: Making an Informed Choice

When selecting your truck tool box lights, consider these critical features to ensure optimal performance and longevity:

- Brightness (Lumens): Measured in lumens, this indicates how bright the light is. For a tool box, 300-600 lumens is generally sufficient for good visibility. Too bright can cause glare, too dim defeats the purpose.

- Power Source & Efficiency: Decide between battery-powered convenience and wired reliability. For wired options, look for energy-efficient LEDs that won’t significantly drain your truck’s battery.

- Durability & IP Rating: Your tool box lights will be exposed to dust, dirt, moisture, and temperature fluctuations. Look for an IP (Ingress Protection) rating. IP65 or higher is recommended, indicating resistance to dust and low-pressure water jets.

- Mounting Options: Common options include strong adhesive backing, magnetic strips, or screw-in clips. Consider the interior surface of your tool box and how securely you want the lights mounted.

- Activation Methods:

- Manual Switch: Simple on/off toggle.

- Pressure Switch: Activated when the tool box lid is opened or closed.

- Motion Sensor: Turns on when movement is detected.

- Vibration Sensor: Less common, but can activate upon truck movement or opening.

- Color Temperature: Measured in Kelvin (K), this determines the "warmth" or "coolness" of the light.

- Warm White (2700K-3000K): Softer, yellowish light.

- Cool White/Daylight (4000K-6500K): Brighter, more natural light, ideal for tasks requiring good color rendering and detail.

- Ease of Installation: Unless you’re an experienced DIYer, look for kits that offer straightforward installation with clear instructions.

Installation Guide: How to Light Up Your Tool Box

Installing truck tool box lights can be a simple DIY project. Here’s a step-by-step guide for common LED strip installations:

- Plan Your Layout:

- Open your tool box and assess the best placement for maximum illumination. Common areas include the underside of the lid, along the top inside edges, or vertically in corners.

- Consider where the power source will be located (battery pack or wiring entry point).

- Measure the lengths of LED strips needed.

- Gather Your Materials:

- LED light kit (strips, power source, switch).

- Isopropyl alcohol and clean cloth for surface prep.

- Wire cutters/strippers (for wired systems).

- Electrical tape, heat shrink tubing, or crimp connectors (for wired systems).

- Zip ties or cable clips for wire management.

- Drill and small bit (if mounting a switch or routing wires through metal).

- Fuse holder and fuse (for wired systems, essential for safety).

- Prepare the Surface:

- Thoroughly clean the interior surfaces where the lights will be mounted. Use isopropyl alcohol to remove any grease, dirt, or residues. This is crucial for the adhesive to stick properly. Let it dry completely.

- Mount the Lights:

- Carefully peel the backing off the LED strip’s adhesive.

- Press the strip firmly onto the chosen surface, applying even pressure along its entire length. Work in small sections to avoid kinks or bubbles.

- If using magnetic lights or puck lights, simply attach them to desired metal surfaces or use their adhesive backing.

- Wiring (for 12V Systems):

- Identify a Power Source: The simplest is to tap into an existing 12V power line in your truck, such as the tail lights (though this means lights only work when headlights are on), or run a dedicated wire directly from the truck battery (recommended for constant power).

- Run Wires Safely: Route wires along existing vehicle harnesses or frame rails, away from moving parts, hot components, or sharp edges. Use zip ties or cable clips to secure them.

- Install a Fuse: ALWAYS install an inline fuse (e.g., 5A or 10A) as close to the power source (truck battery) as possible. This protects your truck’s electrical system and the lights from power surges.

- Connect the Switch: Wire an inline switch into the positive (+) power line leading to your lights. You can opt for a simple toggle switch or a pressure/motion-activated switch for automatic operation.

- Ground the System: Connect the negative (-) wire from your lights to a good chassis ground point on your truck (e.g., a clean bolt on the frame).

- Test the Lights:

- Before tidying up all the wires, test the system. Turn on the switch (or open/close the lid if using a pressure switch) to ensure all lights illuminate properly.

- Final Touches:

- Once confirmed working, secure all wiring neatly with zip ties or cable clips. Ensure no wires are dangling or susceptible to damage.

- Close the tool box lid to check for any interference.

Maintenance and Troubleshooting

Maintaining your truck tool box lights is straightforward and ensures their longevity.

- Cleaning: Periodically wipe down the lights with a damp cloth to remove dust and dirt, which can dim their output. Avoid harsh chemicals.

- Battery Replacement/Recharging: If using battery-powered lights, replace batteries as soon as you notice dimming. For rechargeable units, follow manufacturer recommendations for charging cycles.

- Check Connections: For wired systems, occasionally inspect wire connections for corrosion or looseness, especially where exposed to elements.

- Troubleshooting Common Issues:

- Lights Not Working: Check the power source (batteries dead? fuse blown? wire disconnected?). Ensure the switch is functioning.

- Lights Dimming: Low batteries are the most common cause. For wired systems, check for a poor ground connection or insufficient voltage from the truck.

- Lights Flickering: Often indicates a loose connection or a dying battery.

Price Table: Estimated Costs for Truck Tool Box Lights

The cost of truck tool box lights can vary significantly based on type, features, brand, and quality. Here’s an estimated price range to help you budget:

| Type of Light | Key Features & Considerations | Estimated Price Range (USD) | Notes |

|---|---|---|---|

| Basic LED Strip | Adhesive backing, 1-2 meters, manual switch, non-waterproof | $10 – $30 | Good for light use, internal mounting. May not last in harsh conditions. |

| Premium LED Strip | IP65/IP67 waterproof, stronger adhesive, brighter (500+ lumens), can be cut to length, often dimmable, comes with wiring kit | $30 – $70 | Recommended for durability and versatility. Often includes a dedicated switch. |

| LED Puck Lights | Battery-powered (AAA/AA), magnetic/adhesive, 50-100 lumens each, often sold in multi-packs | $15 – $40 (for 2-4 pack) | Great for focused illumination, quick installation. Batteries will need regular replacement. |

| Motion-Activated Lights | Battery-powered, built-in PIR sensor, often LED strip or puck light style | $25 – $60 | Convenient, power-saving. May require specific placement to avoid false triggers. |

| Complete Wired Kit | Dedicated LED bars/strips, robust wiring, fuse, pressure switch or toggle switch, professional appearance | $50 – $120 | Best for permanent, integrated solutions. Requires more involved installation, but offers reliable, consistent power. |

| Heavy-Duty/Industrial | High lumen output (800+), extremely durable housing, military-grade connectors, extreme IP ratings, often custom-fit | $100 – $300+ | For demanding professional use, often with advanced features like remote control or app integration. |

Note: These are estimated prices and can fluctuate based on sales, brand reputation, and specific features.

Frequently Asked Questions (FAQ)

Q1: Will truck tool box lights drain my truck’s battery?

A1: If you use battery-powered lights, no, they won’t affect your truck’s battery. For wired 12V lights, if installed correctly with a low-draw LED system and an appropriate switch, the drain is negligible. However, leaving them on for extended periods (days) without the truck running could, theoretically, cause a minor drain. Using a pressure switch that turns lights off when the lid is closed is the best way to prevent this.

Q2: Are all truck tool box lights waterproof?

A2: No. It’s crucial to check the IP (Ingress Protection) rating. Look for IP65 or higher, which indicates resistance to dust and water jets. Lights with lower IP ratings (e.g., IP20) are only suitable for dry, indoor environments and will fail quickly in a truck tool box.

Q3: Can I install these lights myself, or do I need a professional?

A3: Most battery-powered and many adhesive LED strip kits are designed for easy DIY installation. Wired 12V systems require basic electrical knowledge (identifying power/ground, using connectors, installing a fuse). If you’re uncomfortable with wiring, it’s always best to consult an auto electrician to avoid damage to your truck’s electrical system.

Q4: How bright should my tool box lights be?

A4: For general illumination, 300-600 lumens is usually sufficient. If your tool box is very large, deep, or has many compartments, you might consider higher lumen output or multiple light strips for even distribution.

Q5: What’s the best type of light for a truck tool box?

A5: LED light strips are generally considered the best all-around option due to their even light distribution, flexibility, and energy efficiency. For convenience, motion-activated or pressure-activated systems are excellent. The "best" type ultimately depends on your specific needs, budget, and desired level of installation effort.

Conclusion

Truck tool box lights are a simple yet profoundly effective upgrade for any truck owner. They transform a often-overlooked, dark space into a well-lit, organized, and efficient storage area. By investing in the right lighting solution, you not only save valuable time and reduce frustration but also enhance your safety and prolong the life of your tools. From the versatility of LED strips to the convenience of motion sensors, there’s a perfect lighting system out there to meet your needs. Embrace the power of illumination and make fumbling in the dark a thing of the past – your tools, your efficiency, and your peace of mind will thank you for it.

Trucks for Sale Find the best deals on used trucks for sale across the USA. Browse pickups, semi trucks, dump trucks and more – updated daily

Trucks for Sale Find the best deals on used trucks for sale across the USA. Browse pickups, semi trucks, dump trucks and more – updated daily