Tool Box Lights Trucks: Illuminating Your Mobile Workshop

For truck owners, contractors, tradespeople, and even dedicated DIY enthusiasts, a truck’s toolbox is more than just a storage container; it’s a mobile workshop, a repository of essential tools, and often, a lifeline on the job or during an emergency. However, accessing the right tool quickly, especially in low-light conditions, can be a frustrating, time-consuming, and even dangerous endeavor. This is where tool box lights trucks become an indispensable upgrade.

Tool box lights trucks refer to specialized lighting solutions designed to illuminate the interior of truck-mounted toolboxes. These lights transform a dark, cavernous space into a brightly lit, organized area, ensuring that every wrench, drill bit, or fastener is easily visible and accessible, regardless of the time of day or the ambient light conditions. From simple adhesive LED strips to sophisticated integrated systems, these lighting solutions are a game-changer for anyone who relies on their truck toolbox.

The Unseen Advantages: Why Tool Box Lights Trucks Are a Must-Have

The benefits of installing tool box lights trucks extend far beyond simple visibility. They contribute significantly to efficiency, safety, and overall professionalism.

- Enhanced Visibility: The most obvious benefit. Whether you’re working at dawn, dusk, night, or in dimly lit environments like garages or underpasses, a well-lit toolbox ensures you can immediately identify and retrieve the tool you need. No more fumbling, using your phone’s flashlight, or relying on inadequate external lighting.

- Increased Efficiency and Productivity: Time is money, especially for professionals. With clear visibility, you spend less time searching for tools and more time getting the job done. This translates directly into improved workflow and reduced project times.

- Safety First: Working in the dark with sharp tools can be hazardous. Tool box lights trucks minimize the risk of accidental cuts, scrapes, or dropping tools on your feet. They also help prevent misplacing small, critical components that could cause a tripping hazard or be difficult to find later.

- Professionalism and Organization: A well-lit and organized toolbox reflects positively on your professionalism. It shows attention to detail and a commitment to efficiency, which can impress clients and colleagues alike. It also encourages better organization, as everything has a visible place.

- Versatility Beyond Tools: While primarily for tools, these lights can illuminate other items stored in your truck bed or toolbox, such as camping gear, emergency supplies, or sports equipment. They can even serve as impromptu work lights in a pinch.

- Reduced Frustration: The simple act of easily finding what you need, when you need it, can significantly reduce job-site frustration, leading to a more positive and productive experience.

Types of Tool Box Lights for Trucks: Choosing Your Illumination

The market offers a variety of tool box lights trucks, each with its own characteristics, benefits, and ideal applications. Understanding these types will help you select the best fit for your needs.

-

LED Strip Lights: These are arguably the most popular and versatile option. They consist of a flexible strip embedded with numerous small LED diodes, often with an adhesive backing for easy installation.

- Features: Available in various lengths, brightness levels (lumens), and often come with a protective silicone or epoxy coating for water and dust resistance. They are typically powered by 12V DC (from your truck’s battery) or sometimes via USB or a separate battery pack.

- Pros: Highly customizable, provide even illumination, easy to install, energy-efficient, and affordable.

- Cons: Can be susceptible to damage if not properly protected, and wiring requires some basic knowledge.

-

Puck Lights / Spot Lights: These are smaller, circular, or rectangular individual lights that provide more focused illumination. They can be mounted strategically to highlight specific areas or tools.

- Features: Often battery-powered (AA, AAA, or coin cell) for wire-free installation, or 12V DC. Some have magnetic backs for easy repositioning.

- Pros: Simple installation (often peel-and-stick or magnetic), good for targeted lighting, very compact.

- Cons: May require multiple units for full coverage, battery life can be a concern if heavily used, less even illumination than strips.

-

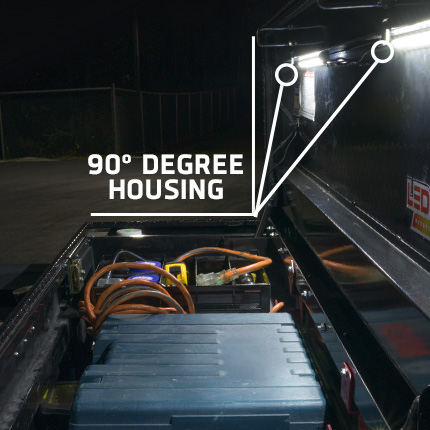

Under-Lid Lights: Specifically designed to attach to the underside of the toolbox lid, these lights illuminate the entire interior when the lid is open. They often incorporate a switch that activates when the lid is lifted.

- Features: Integrated switch mechanisms (magnetic or pressure-activated), robust housings, and often a single, powerful light source or a short LED strip.

- Pros: Automatic operation, excellent coverage when the lid is open, neat and integrated appearance.

- Cons: May not be ideal if you frequently work with the lid closed or partially open, can be more expensive.

-

Rechargeable/Portable Lights: While not permanently installed, a high-quality rechargeable work light or magnetic LED bar can serve as an excellent supplementary lighting solution for your toolbox.

- Features: Built-in rechargeable batteries (USB charging), often with magnetic bases, hooks, or stands.

- Pros: Highly versatile, can be used inside and outside the toolbox, no wiring required.

- Cons: Requires manual charging, can be misplaced, not a permanent integrated solution.

Installation Guide: How to Equip Your Tool Box Lights Trucks

Installing tool box lights trucks is a manageable DIY project, but it requires careful planning and execution, especially when dealing with your truck’s electrical system.

-

Gather Your Materials:

- Chosen lights (LED strips, puck lights, etc.)

- Wire (16-18 gauge recommended for 12V, if not included)

- Wire cutters/strippers, crimpers

- Heat shrink tubing or electrical tape

- Inline fuse holder and appropriate fuse (e.g., 3A-5A for most LED strips)

- Connectors (butt connectors, spade connectors)

- Switch (rocker, push-button, magnetic, or pressure-activated)

- Zip ties or cable clips for wire management

- Rubbing alcohol or surface cleaner

- Optional: Soldering iron, multimeter

-

Plan Your Layout:

- Determine where you want the lights inside the toolbox for optimal illumination. Consider the lid, top edges, or even vertically along the sides.

- Map out the wiring path from the lights to your power source (truck battery or an existing accessory wire) and the switch location.

-

Prepare the Surface:

- Clean the interior surfaces of your toolbox thoroughly with rubbing alcohol. This is crucial for adhesive-backed lights to stick securely. Let it dry completely.

-

Mount the Lights:

- LED Strips: Peel off the adhesive backing and carefully press the strip firmly onto the chosen surface. For added security, use small mounting clips or a dab of silicone adhesive, especially in high-vibration environments.

- Puck Lights: Follow the manufacturer’s instructions, usually peel-and-stick or screw mounting.

- Under-Lid Lights: Mount according to instructions, ensuring the integrated switch aligns correctly to activate when the lid opens.

-

Wiring (for 12V DC lights):

- Power Source: The safest and most common method is to run a dedicated wire from your truck’s battery. ALWAYS include an inline fuse holder with an appropriately sized fuse (e.g., 3-5 amps) as close to the battery as possible. Connect the positive wire from the battery to one side of your switch.

- Switch Installation: Mount your chosen switch (rocker, push-button, etc.) in a convenient, accessible location. Run the fused positive wire to one terminal of the switch. Run another wire from the other terminal of the switch to the positive lead of your lights.

- Ground Connection: Connect the negative wire from your lights directly to a good chassis ground point on your truck (a clean, unpainted metal surface) or directly to the negative terminal of your battery.

- Magnetic/Pressure Switches: If using an automatic switch, follow its specific wiring diagram. These often interrupt the positive wire to the lights when the lid is closed.

-

Test the System:

- Before tidying up, connect everything and test the lights. Ensure they turn on and off correctly with the switch and that there are no shorts.

-

Cable Management:

- Once tested, use zip ties, cable clips, or wire loom to neatly secure all wiring, preventing it from snagging, chafing, or getting pinched by the toolbox lid. Ensure wires are routed away from hot engine components or moving parts.

Key Considerations When Buying Tool Box Lights Trucks

Making an informed decision about your tool box lights trucks involves evaluating several factors:

- Brightness (Lumens): This indicates how much light the unit produces. For most truck toolboxes, 300-600 lumens per foot (for strips) or per light (for pucks) is adequate. More lumens mean brighter light.

- Durability & Weatherproofing (IP Rating): Toolboxes are exposed to dust, moisture, and vibrations. Look for an IP (Ingress Protection) rating of at least IP65 (dust-tight, protected against water jets) or IP67 (dust-tight, protected against temporary immersion).

- Power Source: Decide between 12V DC (hardwired to truck battery), self-contained battery packs (AA/AAA), or USB rechargeable options. 12V offers consistent, long-term power, while battery-powered options are easier to install but require battery replacement/recharging.

- Ease of Installation: Some systems are plug-and-play, while others require basic wiring knowledge. Consider your comfort level with electrical work.

- Switch Type:

- Manual Switch: Gives you full control.

- Magnetic Switch: Activates when the lid opens/closes (great for automatic operation).

- Pressure Switch: Activates when the lid closes on a button (less common for toolboxes).

- Color Temperature: Measured in Kelvin (K). Cool white (5000K-6500K) provides bright, crisp light ideal for task work. Warm white (2700K-3500K) is softer, more like traditional incandescent.

- Length/Coverage: Ensure the lights you choose provide adequate coverage for the size and configuration of your toolbox.

- Brand Reputation & Warranty: Opt for reputable brands that offer a warranty, ensuring product quality and support.

Maintenance and Troubleshooting for Your Tool Box Lights Trucks

Once installed, tool box lights trucks generally require minimal maintenance, but occasional checks can prolong their lifespan.

- Regular Cleaning: Periodically wipe down the light lenses and strips to remove dust, dirt, and grime that can diminish brightness.

- Wiring Inspection: Every few months, visually inspect all wiring connections for corrosion, fraying, or loose terminals. Re-secure or replace as needed.

- Fuse Check: If your lights stop working, the first thing to check is the inline fuse. A blown fuse indicates an overload or short circuit. Replace it with a fuse of the same amperage.

- Battery Replacement/Recharge: For battery-powered lights, replace batteries as soon as they dim or fail, or ensure rechargeable units are topped up.

- Adhesive Integrity: Over time, adhesive backings can weaken. If your LED strips start to peel, re-secure them with a stronger adhesive or small mounting clips.

Common Troubleshooting:

- Lights not turning on: Check fuse, check all connections (positive, negative, switch), test switch functionality, ensure power source is live.

- Lights flickering/dim: Could indicate a loose connection, low battery (if applicable), or an overloaded circuit (unlikely with LEDs, but possible if other accessories are added).

Price Table: A Snapshot of Tool Box Lights Trucks Options

This table provides general price ranges and characteristics for various tool box lights trucks options. Prices can vary significantly based on brand, features, and quality.

| Light Type | Typical Price Range (USD) | Key Features | Pros | Cons |

|---|---|---|---|---|

| LED Strip Lights | $15 – $60 | 1-5 meters, IP65/IP67, 12V DC, adhesive backing | Flexible, even light, energy-efficient, customizable | Wiring required, adhesive can fail, less robust |

| LED Puck Lights | $10 – $35 (for 2-4 pack) | Battery-powered (AA/AAA), push-button/remote, magnetic | Wire-free, easy install, portable | Battery life, less uniform light, lower brightness |

| Under-Lid LED Bars | $30 – $80 | Integrated magnetic/pressure switch, durable housing | Automatic operation, neat, good full-lid coverage | Less flexible placement, specific to lid mounting |

| Rechargeable LED Work Light | $20 – $100+ | USB rechargeable, magnetic base, multi-mode, high lumens | Highly versatile, portable, no wiring needed | Not permanently installed, requires manual charging |

Note: Prices are estimates and can vary based on brand, quality, and specific features.

Frequently Asked Questions (FAQ) about Tool Box Lights Trucks

Q1: Are LED strip lights waterproof enough for a truck toolbox?

A1: Look for LED strips with an IP (Ingress Protection) rating of IP65 or higher. IP65 means they are protected against dust and low-pressure water jets, which is generally sufficient for most toolbox environments, protecting against rain and splashes. For extreme conditions, IP67 (protected against temporary immersion) is even better.

Q2: How do I power my tool box lights?

A2: Most permanent tool box lights trucks are powered by your truck’s 12V DC electrical system. This involves connecting them to the truck battery (always with an inline fuse!) or tapping into an existing accessory wire. Some simpler options use internal batteries (AA/AAA) or are USB rechargeable.

Q3: What’s the best way to turn them on/off?

A3: Common options include a manual rocker or push-button switch, a magnetic switch (activates when the toolbox lid opens), or a pressure switch (activates when the lid is lifted off a button). Magnetic switches are often preferred for their automatic, hands-free operation.

Q4: Can I install tool box lights trucks myself?

A4: Yes, most tool box lights trucks are designed for DIY installation. However, wiring to your truck’s electrical system requires basic knowledge of wiring, using fuses, and making secure connections. If you’re uncomfortable with electrical work, it’s best to consult a professional.

Q5: What brightness (lumens) do I need for my toolbox?

A5: For most standard truck toolboxes, 300-600 lumens per foot (for LED strips) or per individual light is usually sufficient to provide excellent visibility. For very large toolboxes or those with many compartments, you might want to aim for higher lumens or use multiple light sources.

Q6: Will tool box lights drain my truck battery?

A6: Modern LED tool box lights trucks are very energy-efficient and draw minimal power. If properly installed with an inline fuse and a reliable switch, they pose a very low risk of draining your battery, especially if you remember to turn them off (or if you use an automatic switch). Only very prolonged use with the engine off might have a noticeable impact.

Conclusion: Shedding Light on Productivity

Tool box lights trucks are a small investment that yields significant returns in terms of efficiency, safety, and convenience. They transform a dark, often frustrating, storage space into a well-lit, organized workstation, empowering you to find what you need instantly and work more effectively, day or night. Whether you’re a professional on a demanding job site or a weekend warrior tackling home projects, illuminating your mobile workshop is a smart upgrade that you’ll appreciate every time you open your toolbox. Embrace the light, enhance your productivity, and make your truck truly work for you.

Trucks for Sale Find the best deals on used trucks for sale across the USA. Browse pickups, semi trucks, dump trucks and more – updated daily

Trucks for Sale Find the best deals on used trucks for sale across the USA. Browse pickups, semi trucks, dump trucks and more – updated daily