Side Marker Lights for Trucks: Illuminating Safety and Style

Side Marker Lights for Trucks: Illuminating Safety and Style

In the vast landscape of truck accessories and safety features, side marker lights often go unnoticed until their absence becomes a glaring issue. More than just decorative elements, these small but mighty lights play a critical role in the visibility, safety, and legal compliance of trucks, particularly larger commercial vehicles. This comprehensive guide will delve into every aspect of side marker lights for trucks, from their fundamental purpose to installation, maintenance, and the legalities surrounding them, ensuring you’re well-equipped to make informed decisions for your rig.

The Crucial Role of Side Marker Lights

Side marker lights are essentially small lights mounted on the sides of a truck, typically along its length, designed to indicate the vehicle’s presence, length, and width to other drivers, especially in low-light conditions or at night. They serve multiple vital functions that extend far beyond mere aesthetics.

Enhancing Safety Through Visibility

The primary purpose of side marker lights is to drastically improve a truck’s visibility. Trucks, especially semi-trucks, trailers, and other long vehicles, can be notoriously difficult to gauge in terms of their overall length and width, particularly when turning, changing lanes, or navigating tight spaces. Side marker lights create a clear visual outline of the vehicle, allowing other motorists to:

- Accurately perceive the truck’s dimensions: This prevents other drivers from misjudging the truck’s size, reducing the risk of side-swipe collisions.

- Identify the vehicle from a distance: Even in foggy or rainy conditions, the distinct pattern of side markers helps identify a large vehicle long before its headlights or taillights become fully discernible.

- Understand the truck’s movement: When a truck turns, the pattern of its side markers shifts, providing an early warning to surrounding traffic about its intended path.

Ensuring Legal Compliance

Beyond safety, side marker lights are a non-negotiable legal requirement for most commercial vehicles and trailers in many regions, including the United States (under Department of Transportation – DOT regulations) and Canada. These regulations specify the color (amber for the front and mid-sections, red for the rear), placement, and often the spacing of these lights. Failing to comply can result in hefty fines, vehicle impoundment, and even contribute to liability in the event of an accident. Understanding and adhering to these regulations is paramount for any truck owner or operator.

Adding Aesthetic Appeal

While safety and legality are paramount, side marker lights also offer a significant opportunity for customization and aesthetic enhancement. Modern LED side markers come in various designs, from sleek slimline bars to classic bullet-style lights, allowing truck owners to add a personal touch and give their rig a distinct, professional, or even aggressive look. The uniform glow of well-placed LED markers can transform a truck’s nighttime presence, making it stand out on the road.

Types and Technologies of Side Marker Lights

The evolution of lighting technology has brought significant advancements to side marker lights. Understanding the different types available is crucial for selecting the best fit for your truck.

Incandescent vs. LED Lights

- Incandescent: These are the traditional choice, using a filament bulb to produce light.

- Pros: Lower initial cost, easily replaceable bulbs, warm glow.

- Cons: Higher power consumption, shorter lifespan (filaments can break from vibration), produce heat, less bright, slower illumination.

- LED (Light Emitting Diode): The modern standard, offering superior performance.

- Pros: Extremely long lifespan (50,000+ hours), significantly lower power draw, instant illumination, brighter and more vibrant light, highly durable (no filament to break), resistant to vibration and moisture.

- Cons: Higher initial cost, usually requires replacement of the entire unit if an LED fails.

For trucks, especially those exposed to harsh conditions and constant vibration, LED side marker lights are overwhelmingly recommended due to their durability, efficiency, and longevity, ultimately offering a better return on investment despite a higher upfront cost.

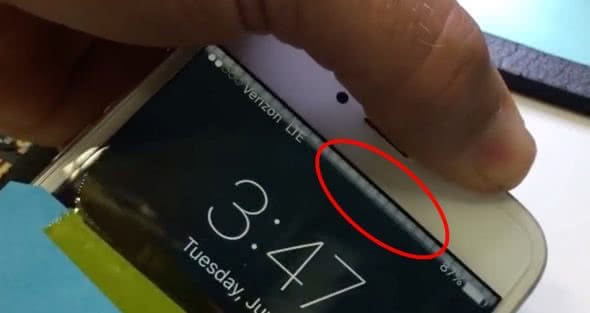

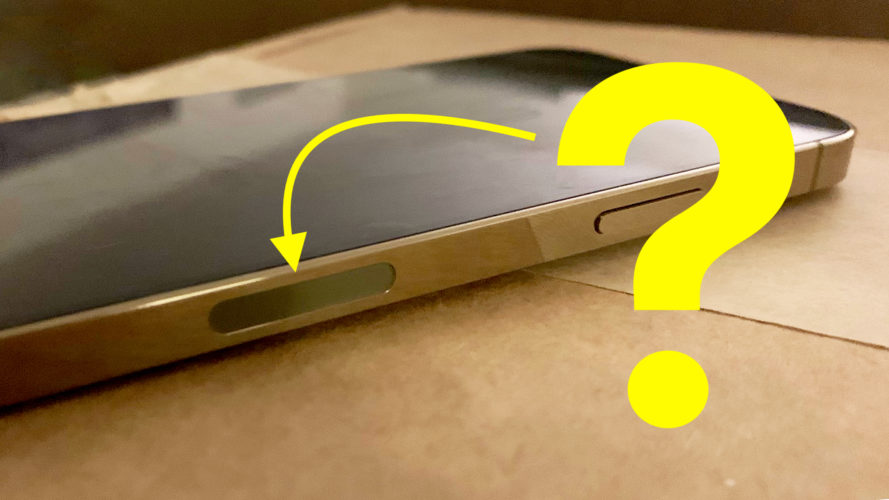

Mounting Styles

Side marker lights come in various mounting configurations to suit different truck body types and aesthetic preferences:

- Surface Mount: The most common type, where the light unit sits on top of the mounting surface. Easy to install.

- Flush Mount: Designed to sit nearly flush with the mounting surface, offering a sleek, integrated look. Requires cutting a hole in the mounting surface.

- Pedestal Mount: Lights mounted on a small stem or bracket, often used for clearance lights but sometimes for side markers on specific truck designs.

- Stud Mount: Features mounting studs on the back that pass through holes in the surface, secured with nuts from the inside.

Lens Colors and Functions

- Amber: Legally required for side markers at the front and along the mid-section of the truck and trailer.

- Red: Legally required for side markers at the rear of the truck and trailer.

- Marker Only: The most basic function, simply illuminates when the truck’s running lights are on.

- Marker with Turn Signal: Some advanced LED side markers can also function as supplemental turn signals, flashing in conjunction with the truck’s primary turn signals for enhanced visibility during lane changes or turns.

- Sequential Turn Signal: A more modern and eye-catching feature where individual LEDs illuminate in sequence, creating a dynamic "flowing" effect when the turn signal is activated.

Installation Guide: A Step-by-Step Approach

Installing side marker lights can be a straightforward DIY project, but it requires careful attention to detail to ensure proper function and legal compliance.

-

Preparation and Planning:

- Check Local Regulations: Before starting, confirm the specific requirements for side marker placement, spacing, and color in your region.

- Gather Tools: You’ll typically need a drill, drill bits, wire strippers, crimpers, heat shrink tubing or electrical tape, a measuring tape, marker, screwdriver, and the new lights.

- Disconnect Power: Always disconnect the truck’s battery before working on electrical systems to prevent short circuits or shocks.

- Determine Placement: Measure and mark the exact locations where each light will be installed, ensuring even spacing and compliance with legal requirements (e.g., maximum distance from the front/rear, maximum spacing between lights).

-

Mounting the Lights:

- Drill Pilot Holes: Carefully drill pilot holes for the mounting screws according to the light’s specifications. For flush-mount lights, you’ll need to cut a larger opening.

- Secure the Lights: Attach the light units to the truck’s frame or body using the provided screws or mounting hardware. Ensure they are firmly secured and won’t vibrate loose.

-

Wiring the Lights:

- Identify Wires: Most side marker lights have two wires: a positive (+) and a negative (-) or ground. Some multi-function lights may have a third wire for a turn signal function.

- Tap into Existing Circuit: Locate an existing running light circuit that powers your truck’s other marker or clearance lights. This ensures the new side markers illuminate when your other lights are on. Use a multimeter to confirm the correct wire.

- Strip Wires: Carefully strip a small section of insulation from both the truck’s existing wire and the new light’s wires.

- Make Connections:

- Positive to Positive: Connect the positive wire from the new light to the positive wire of the existing running light circuit.

- Negative to Ground: Connect the negative (ground) wire from the new light to a clean, unpainted metal surface on the truck’s chassis (frame ground) or directly to the truck’s main ground wire.

- Optional Third Wire: If your lights have a turn signal function, connect this wire to the corresponding turn signal wire of your truck.

- Secure Connections: Use crimp connectors or solder for secure and durable connections.

- Insulate Connections: Cover all exposed wires and connections with heat shrink tubing or high-quality electrical tape to prevent short circuits and protect against moisture.

-

Testing and Sealing:

- Reconnect Battery: Reconnect the truck’s battery.

- Test Functionality: Turn on your truck’s running lights and test all newly installed side markers to ensure they illuminate correctly. Test turn signals if applicable.

- Weatherproof: Apply a bead of silicone sealant around the edges of surface-mounted lights, especially if not pre-gasketed, to prevent water intrusion. Ensure all wire entry points are sealed.

Important Considerations Before Purchase & Installation

Making the right choice for side marker lights involves more than just picking a color.

- Legal Compliance (DOT/FMVSS): Always ensure the lights are DOT compliant. Look for the "DOT" stamp or marking on the lens. Non-compliant lights can lead to fines and safety risks.

- Durability and Weather Resistance: Trucks operate in harsh environments. Look for lights with an IP (Ingress Protection) rating of IP67 or higher, indicating strong resistance to dust and water. High-quality materials like polycarbonate lenses and robust housings are crucial.

- Brightness and Beam Pattern: While brighter is generally better for visibility, ensure the light isn’t so intense that it blinds other drivers. A wide beam pattern ensures maximum coverage.

- Power Consumption: LED lights are highly efficient, which is beneficial for your truck’s electrical system, especially if you’re adding many lights.

- Compatibility: Ensure the lights are compatible with your truck’s voltage system (typically 12V or 24V).

- Warranty and Brand Reputation: Invest in lights from reputable manufacturers that offer a warranty, indicating confidence in their product’s quality and lifespan.

Maintenance and Troubleshooting

Maintaining your side marker lights is simple and ensures their continued effectiveness.

- Regular Inspection: Periodically check all side markers for cracks, discoloration, dimness, or non-functionality. This is particularly important during pre-trip inspections.

- Cleaning: Keep the lenses clean from dirt, grime, and road salt to ensure maximum light output. Use a mild soap and water solution.

- Replacing Incandescent Bulbs: If you have incandescent markers, replace burnt-out bulbs promptly. Keep spares on hand.

- Troubleshooting LED Issues:

- Flickering/Dimming: Could indicate a loose connection, a failing ground, or an issue with the truck’s voltage regulator.

- Not Working: Check the fuse for the circuit, then inspect all wiring connections for corrosion or breaks. A multimeter can help trace power. If individual LEDs are out, the entire unit usually needs replacement.

Practical Advice and Actionable Insights

- Don’t Skimp on Quality: While budget options exist, investing in high-quality, durable LED side markers from reputable brands will save you money and headaches in the long run. Cheap lights often fail quickly due to vibration and moisture.

- Consider Future Upgrades: If you’re doing a full rewire, consider running extra wires or using larger gauge wire for future additions like sequential turn signals or additional marker lights.

- Always Check Local Regulations: Even if a light is DOT compliant, specific state or provincial laws might have additional nuances regarding placement or quantity.

- Professional Installation for Complex Setups: While basic installation is DIY-friendly, if you’re integrating multi-function lights, complex wiring, or don’t feel confident, a professional auto electrician or truck shop can ensure a safe and compliant installation.

Side Marker Lights for Trucks: Price Table

| Type/Style | Material | Features | Price Range (USD) | Notes |

|---|---|---|---|---|

| Standard LED Marker | Polycarbonate Lens, ABS Base | Amber/Red, Waterproof (IP67), 2-wire | $5 – $15 | Basic, reliable, single-function |

| Slimline LED Marker | Polycarbonate Lens, Aluminum Base | Low Profile, Waterproof (IP67), 2-wire | $8 – $20 | Sleek design, ideal for tight spaces |

| Heavy-Duty LED Marker | Reinforced Polycarbonate, Rubber Base | Vibration Resistant, Extra Durable, IP68 | $12 – $30 | Built for extreme conditions, longer lifespan |

| LED Marker w/ Turn Signal | Polycarbonate Lens, ABS Base | Marker + Flashing Turn Signal, 3-wire | $15 – $35 | Enhanced visibility for lane changes/turns |

| Sequential LED Marker | Polycarbonate Lens, ABS Base | Marker + Dynamic Sequential Turn Signal, 3-wire | $25 – $60+ | Modern aesthetic, highly visible turn indicator |

| Incandescent Marker | Acrylic Lens, Metal Base | Amber/Red, Replaceable Bulb | $3 – $10 | Traditional, lower initial cost, higher maintenance |

| Multi-Function LED Bar | Aluminum Housing, Polycarbonate Lens | Multiple LEDs, Integrated Marker/Turn/Brake | $40 – $100+ | Often used for rear or side-skirts, high visibility |

Note: Prices are approximate and can vary based on brand, quality, quantity purchased, and retailer.

Frequently Asked Questions (FAQ)

Q1: Are side marker lights legally required on all trucks?

A1: Yes, in most jurisdictions, including the U.S. (under DOT regulations), side marker lights are legally required for commercial trucks, trailers, and other vehicles exceeding certain length or width specifications. Always check your local and federal regulations.

Q2: Can I use any color for my side marker lights?

A2: No. Legally, side marker lights must be amber for the front and mid-sections of the vehicle and red for the rear. Using other colors (like blue or green) is illegal and can lead to fines.

Q3: What’s the difference between side marker lights and clearance lights?

A3: Side marker lights illuminate the sides of the vehicle to indicate its length and presence. Clearance lights, often found on the top corners of large vehicles, indicate the vehicle’s overall width and height. While they serve similar visibility functions, their placement and specific regulatory definitions differ.

Q4: How often should I check my side marker lights?

A4: Side marker lights should be checked as part of your regular pre-trip inspection, ideally every time before you operate the truck, especially for commercial vehicles. This ensures they are always functioning correctly for safety and legal compliance.

Q5: Can I install side marker lights myself, or do I need a professional?

A5: Basic side marker light installation is a common DIY project for those with basic electrical knowledge and tools. However, for complex wiring, multi-function lights, or if you’re unsure, professional installation is recommended to ensure safety, proper function, and legal compliance.

Q6: Why are my LED side marker lights flickering or dimming?

A6: Flickering or dimming in LED lights can indicate a few issues: a loose or corroded wire connection, a poor ground connection, insufficient voltage, or a failing voltage regulator in the truck’s electrical system. Less commonly, it could be a sign of a failing LED unit itself.

Conclusion

Side marker lights are far more than just small bulbs on the side of a truck; they are integral safety components that play a vital role in preventing accidents, ensuring legal compliance, and enhancing a truck’s overall presence on the road. Investing in high-quality, durable LED side markers, understanding their proper installation, and adhering to legal requirements are crucial steps for any truck owner or operator. By illuminating your truck effectively, you not only protect your investment but, more importantly, contribute to the safety of everyone sharing the road.