LED Brake Light Strip with Turn Signals for Trucks: Elevate Your Truck’s Safety and Style

LED Brake Light Strip with Turn Signals for Trucks: Elevate Your Truck’s Safety and Style

In the vast landscape of automotive accessories, few innovations offer the dual benefits of enhanced safety and striking aesthetics quite like the LED brake light strip with integrated turn signals for trucks. Far more than just an add-on, these versatile lighting solutions are transforming how trucks communicate their intentions on the road, providing a brighter, faster, and more dynamic visual warning to fellow motorists. Whether you’re a professional driver, an off-road enthusiast, or simply a truck owner who values both form and function, understanding the power of these LED strips is the first step towards a safer and more stylish ride.

This comprehensive guide will delve into every aspect of LED brake light strips with turn signals, from their fundamental benefits and diverse types to detailed installation insights, crucial buying considerations, and essential maintenance tips. Prepare to illuminate your understanding and empower your truck with the cutting-edge visibility it deserves.

What Are LED Brake Light Strips with Turn Signals?

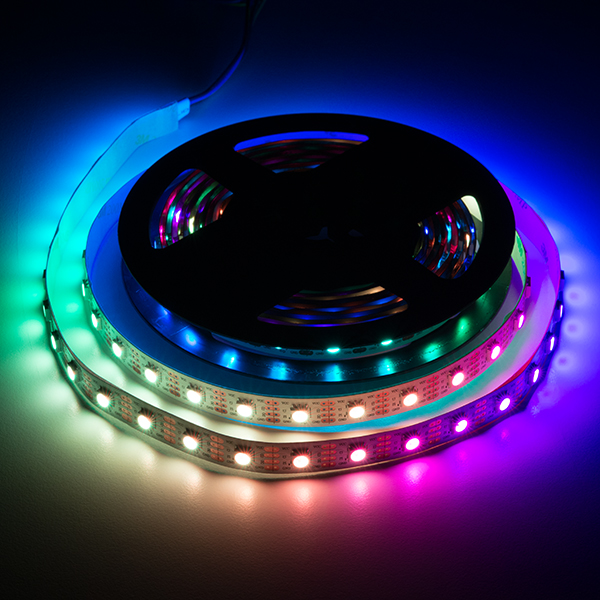

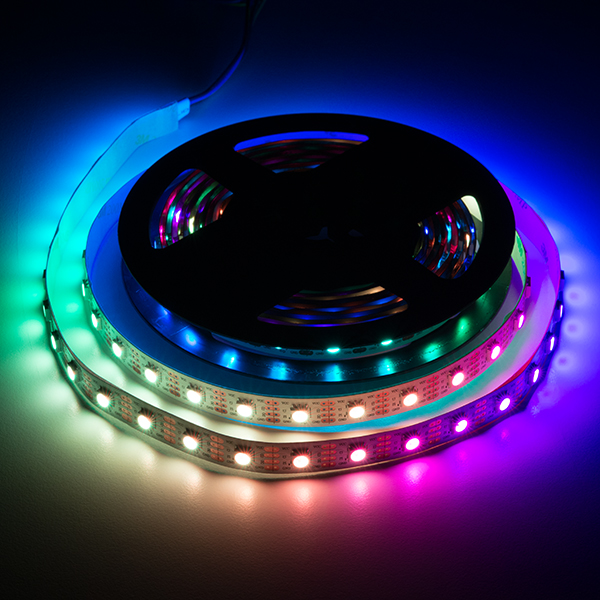

At its core, an LED brake light strip with turn signals is a flexible, weather-resistant strip embedded with numerous light-emitting diodes (LEDs) designed to be mounted on the rear of a truck, typically along the tailgate or bumper. Unlike traditional incandescent bulbs, these strips leverage LED technology to provide multiple lighting functions within a single unit:

- Running Lights: A continuous, often dim, illumination when the truck’s headlights are on, enhancing rear visibility.

- Brake Lights: A significantly brighter illumination when the brake pedal is pressed, clearly signaling deceleration.

- Turn Signals: Dynamic amber or red lights that flash to indicate a left or right turn, often with a sequential or chasing effect for added visual impact.

- Reverse Lights (Optional): Some advanced strips may include white LEDs that illuminate when the truck is put into reverse.

These strips are engineered to connect directly into your truck’s existing taillight wiring harness, drawing power from the 12-volt electrical system and synchronizing with your vehicle’s standard lighting commands. Their flexible design allows them to conform to various surfaces, making them a popular choice for a custom, yet highly functional, upgrade.

Why Upgrade? Benefits for Truck Owners

The transition from conventional lighting to LED brake light strips with turn signals offers a multitude of compelling advantages for truck owners:

- Enhanced Safety & Visibility: This is arguably the most significant benefit. LEDs illuminate instantly—milliseconds faster than incandescent bulbs. At highway speeds, this seemingly small delay translates to crucial extra feet of reaction time for following drivers. Their superior brightness and often wider light dispersion ensure your truck is seen sooner and more clearly, especially in adverse weather conditions or at night. Sequential turn signals, in particular, provide a highly intuitive visual cue, guiding the eye in the direction of the turn.

- Increased Durability & Lifespan: LEDs are solid-state devices, meaning they have no fragile filaments to break. They are highly resistant to vibration, shock, and temperature fluctuations, making them ideal for the rugged environment of a truck. This robust construction translates to a significantly longer lifespan, often tens of thousands of hours, reducing the need for frequent replacements.

- Superior Energy Efficiency: LEDs consume far less power than traditional bulbs. While this might not drastically impact your fuel economy, it reduces the load on your truck’s electrical system, potentially prolonging the life of your alternator and battery.

- Customization & Aesthetics: Beyond functionality, these strips offer a sleek, modern look that can dramatically enhance your truck’s rear profile. With various lengths, brightness levels, and lighting patterns available (from simple flash to dynamic sequential effects), you can personalize your truck’s appearance to stand out from the crowd.

- Relatively Easy Installation: While some wiring knowledge is beneficial, many LED brake light strips are designed for DIY installation, often featuring plug-and-play connectors or clearly labeled wires, making them an accessible upgrade for many truck owners.

- Compliance & Legality: Reputable LED strips are designed to meet or exceed Department of Transportation (DOT) and Society of Automotive Engineers (SAE) standards, ensuring they are legal for road use. Always verify compliance before purchasing.

Types and Features to Look For

When selecting an LED brake light strip, consider these key features:

- Length and Flexibility: Strips typically range from 48 to 60 inches to fit various tailgate widths. Ensure the length matches your truck. Flexibility is crucial for conforming to curved surfaces.

- Brightness (Lumens & LED Count): More LEDs and higher lumen output generally mean brighter illumination. Look for strips with high-intensity LEDs for maximum visibility.

- Waterproofing (IP Rating): Trucks are exposed to the elements. An IP (Ingress Protection) rating of IP67 or IP68 indicates excellent resistance to dust and water immersion, crucial for longevity.

- Wiring Harness & Connector Type: Some strips come with a standard 4-pin flat trailer connector for easy plug-and-play installation if your truck has one. Others require splicing into the existing taillight wires. Look for durable, well-insulated wiring.

- Lighting Modes:

- Standard: Basic running, brake, and flashing turn signals.

- Sequential Turn Signals: LEDs illuminate in a flowing sequence from the inside out, providing a distinct and modern look.

- Brake Flash: Some strips offer a rapid flash when brakes are first applied, drawing immediate attention before solid illumination.

- Reverse Light Integration: White LEDs for backing up.

- Mounting Options: Most strips use strong adhesive backing (3M VHB tape is common) for primary attachment, often supplemented with screws for added security.

Installation Guide: A Step-by-Step Approach

Installing an LED brake light strip can be a straightforward DIY project with the right tools and patience.

Tools You’ll Need:

- Wire strippers/crimpers

- Electrical tape or heat-shrink tubing

- Zip ties or cable clips

- Rubbing alcohol and a clean cloth

- Measuring tape

- Drill (if using screws)

- Multimeter (optional, but highly recommended for identifying wires)

- Load resistors (if experiencing hyper-flashing after installation)

Installation Steps:

-

Preparation & Test Fit:

- Clean the mounting surface thoroughly with rubbing alcohol to ensure optimal adhesive bonding. Let it dry completely.

- Temporarily position the LED strip to determine the ideal placement (usually along the bottom edge of the tailgate or bumper) and ensure it doesn’t interfere with tailgate operation.

- Route the wiring harness to where you’ll connect it to your truck’s existing taillight wiring.

-

Identify Wiring: This is the most critical step. Your truck’s taillight harness will have wires for:

- Ground (-)

- Running Lights (+)

- Brake Lights (+)

- Left Turn Signal (+)

- Right Turn Signal (+)

- Reverse Lights (+) (if applicable)

- Use your truck’s owner’s manual or a wiring diagram specific to your make/model. Alternatively, a multimeter is invaluable:

- Connect the multimeter’s black lead to a known ground.

- With the truck on (engine off, parking brake engaged), test each wire in the taillight harness while having a helper activate running lights, brakes, left turn, right turn, and reverse. Note which wire corresponds to which function by the voltage reading.

-

Wire Connection:

- Most LED strips come with color-coded wires. Match them to the corresponding wires on your truck’s harness.

- Strip a small section of insulation from both the truck’s wires and the LED strip’s wires.

- Use crimp connectors, solder, or high-quality T-taps to create secure electrical connections.

- Insulate all connections thoroughly with electrical tape or, ideally, heat-shrink tubing to prevent shorts and protect against moisture.

-

Mounting the Strip:

- Carefully peel the backing from the adhesive strip on the LED light bar.

- Align the strip precisely and press firmly along its entire length to ensure good contact.

- If your strip comes with mounting clips or screws, install them now for added security.

-

Test All Functions:

- Before tidying up the wiring, turn on your truck and test every function: running lights, brake lights, left turn, right turn, and reverse (if applicable).

- Ensure all LEDs illuminate correctly and in the intended sequence.

-

Secure Wiring:

- Use zip ties or cable clips to neatly route and secure the wiring harness, keeping it away from moving parts, exhaust, and sharp edges. This prevents damage and ensures a clean installation.

Troubleshooting Common Issues:

- No Power/Partial Lighting: Check all connections, especially the ground wire. Ensure the fuse for your taillights isn’t blown.

- Hyper-Flashing (Turn Signals Flash Too Fast): This occurs because LEDs draw less power, making the truck’s system think a bulb is out. Install load resistors (one per turn signal circuit) to simulate the resistance of a traditional bulb.

- Flickering/Dimming: Could be a loose connection, inadequate ground, or faulty wiring. Re-check all points.

Important Considerations Before Purchase

- Vehicle Compatibility: Ensure the strip is 12V compatible (standard for trucks). Check the length to match your tailgate width.

- Legal Requirements: Verify that the product is DOT compliant. Some regions may have specific regulations regarding sequential turn signals or brake light patterns.

- Quality of Materials: Invest in a strip made with high-quality LEDs, durable housing, and strong, weather-resistant adhesive. Cheap products often fail quickly.

- Warranty & Customer Support: A good warranty indicates manufacturer confidence. Reliable customer support can be invaluable if you encounter installation issues or product defects.

- Budget: Prices vary widely based on features, quality, and brand. Balance desired features with your budget, prioritizing safety and durability.

Maintenance Tips for Longevity

LED brake light strips are generally low-maintenance, but a few simple practices can extend their life:

- Regular Cleaning: Keep the strip free of dirt, mud, and road grime. Use a soft cloth and mild soap and water. Avoid abrasive cleaners.

- Check Connections: Periodically inspect wiring connections for corrosion or looseness, especially after off-road adventures or harsh weather.

- Inspect for Damage: Look for any cracks in the housing, frayed wires, or signs of impact that could compromise waterproofing or performance.

Potential Challenges and Solutions

- Wiring Confusion:

- Solution: Always use a multimeter to verify wires. Refer to truck-specific wiring diagrams. Take pictures before disconnecting anything.

- Adhesive Failure:

- Solution: Thoroughly clean and degrease the mounting surface. Apply an adhesion promoter if available. Consider supplementing with screws if the surface allows.

- Flickering/Inconsistent Operation:

- Solution: Check for a poor ground connection first. Ensure all splices are secure and insulated. Test the strip directly to a 12V power source to rule out a product defect.

- Hyper-Flashing:

- Solution: Install appropriate load resistors. They get hot, so mount them away from plastic or sensitive components.

Price Table: LED Brake Light Strip with Turn Signals for Trucks

| Product Type/Feature | Brightness/Length | Special Features | Price Range (USD) |

|---|---|---|---|

| Basic Red/Amber Strip | 48" – 60", Standard | Running, Brake, Turn Signal (Flash) | $25 – $50 |

| Standard Sequential Turn Signal Strip | 48" – 60", High | Sequential Turn, Running, Brake | $50 – $80 |

| Premium Sequential + Reverse Light Strip | 48" – 60", Very High | Sequential Turn, Running, Brake, White Reverse | $80 – $120 |

| Heavy-Duty/Off-Road Rated Strip | 48" – 60", Very High | IP68 Rated, Reinforced Wiring, Multi-Function | $100 – $150+ |

| RGB/App-Controlled Strip | 48" – 60", Adjustable | Customizable Colors, App Control, Show Modes | $120 – $200+ |

| Add-on Load Resistor Kit (Pair) | N/A | Prevents hyper-flashing for LED turn signals | $10 – $25 |

Note: Prices are estimates and can vary based on brand, retailer, specific features, and current promotions.

Frequently Asked Questions (FAQ)

Q1: Are these LED light strips legal in all states/regions?

A1: Most reputable LED brake light strips are designed to be DOT compliant, meaning they meet federal safety standards. However, local regulations can vary, especially regarding specific lighting patterns (e.g., rapid brake flash). Always check your local Department of Motor Vehicles (DMV) or equivalent authority’s regulations to ensure full compliance.

Q2: How difficult is the installation process for a DIY enthusiast?

A2: For someone with basic automotive wiring knowledge and the right tools, installation is generally manageable. The most challenging part is correctly identifying the wires in your truck’s harness. If you’re uncomfortable with electrical work, it’s always best to consult a professional installer.

Q3: Will installing this strip cause "hyper-flashing" of my turn signals?

A3: Yes, it’s a common issue. Because LEDs draw less current than incandescent bulbs, your truck’s flasher relay (or BCM/Body Control Module) may interpret the low draw as a burned-out bulb, causing the turn signals to flash rapidly (hyper-flash). This is easily fixed by installing load resistors in parallel with the LED turn signal wires.

Q4: How long do these LED brake light strips typically last?

A4: High-quality LED strips can last for tens of thousands of hours, often exceeding 50,000 hours of operation. This translates to many years of reliable use under normal conditions, far outlasting traditional incandescent bulbs. Factors like environmental exposure, vibration, and manufacturing quality influence lifespan.

Q5: Are they truly waterproof, especially for trucks exposed to harsh weather or off-roading?

A5: Reputable brands offer strips with high IP (Ingress Protection) ratings, typically IP67 or IP68, indicating excellent resistance to dust and water immersion. Look for these ratings to ensure durability in wet conditions, car washes, and off-road environments.

Q6: Can I install this on any truck model?

A6: Most LED brake light strips are designed for universal 12V truck applications. The main considerations are the length of the strip to match your tailgate/bumper width and ensuring you can access and correctly identify your truck’s taillight wiring harness.

Conclusion

The LED brake light strip with turn signals is more than just an accessory; it’s a significant upgrade that fuses advanced safety with undeniable style for any truck. By providing quicker illumination, enhanced brightness, and dynamic signaling, these strips drastically improve your truck’s visibility on the road, offering peace of mind for you and increased reaction time for others. Coupled with their impressive durability and energy efficiency, they represent a smart, long-term investment in your vehicle.

Whether you’re looking to boost safety for daily commutes, enhance your rig’s presence for weekend adventures, or simply give your truck a modern edge, embracing this LED technology is a decision that truly lights up the path ahead. Choose wisely, install confidently, and enjoy the enhanced safety and commanding presence your truck will now project on every journey.