Extended Brake Hoses for Lifted Trucks: A Comprehensive Guide to Safety and Performance

Extended Brake Hoses for Lifted Trucks: A Comprehensive Guide to Safety and Performance

Lifting your truck transforms its appearance and enhances its off-road capability, allowing you to conquer challenging terrains with greater ease. However, this modification also necessitates careful consideration of several critical components, one of the most vital being your brake system. Specifically, extended brake hoses for lifted trucks are not merely an upgrade but a fundamental requirement for maintaining safety and optimal braking performance.

This comprehensive guide will delve into every aspect of extended brake hoses, from understanding their necessity to choosing, installing, and maintaining them. Whether you’re planning a lift or already driving a lifted rig, ensuring your brake lines can handle the increased suspension travel is paramount.

Understanding the Critical Need for Extended Brake Hoses

When a truck’s suspension is lifted, the distance between the chassis (where the hard brake lines are mounted) and the axles (where the calipers and wheel cylinders are located) increases. Standard, factory-length brake hoses are designed for the stock suspension travel. Once a lift kit is installed, especially one that significantly increases wheel articulation and droop (the downward travel of the suspension), these stock hoses become dangerously short.

At full suspension droop – when a wheel is extended downwards, such as when traversing uneven terrain or going over a bump – the original brake hoses can stretch taut. This over-extension places immense stress on the hose material and its fittings. The consequences can range from premature wear and cracking of the hose to a sudden, catastrophic rupture. A snapped brake hose means an immediate loss of hydraulic pressure to that wheel, leading to a significant reduction in braking power, a spongy pedal, and potentially a complete loss of braking capability, putting you and others at severe risk.

Extended brake hoses for lifted trucks address this critical issue by providing the necessary additional length to accommodate the increased suspension travel. They ensure that even at maximum droop or articulation, the brake lines remain slack, preventing dangerous stretching, kinking, or tearing, and preserving the integrity of your braking system.

The Undeniable Benefits of Extended Brake Hoses

Investing in the correct extended brake hoses offers a multitude of advantages that go beyond mere compliance with your lift kit:

- Enhanced Safety: This is the primary and most crucial benefit. By preventing brake hose over-extension and potential rupture, extended hoses directly safeguard your ability to stop your truck effectively, under all driving conditions.

- Optimal Braking Performance: With hoses that can freely move with your suspension, hydraulic pressure is consistently maintained, ensuring a firm brake pedal and responsive stopping power. Stock hoses, when stretched, can subtly restrict fluid flow, leading to a less efficient brake system.

- Increased Durability and Longevity: Designed to withstand the rigors of lifted applications, extended hoses are built to last. They reduce stress on the hose material and fittings, extending the lifespan of your entire brake system components.

- Full Suspension Articulation: For off-road enthusiasts, extended hoses are non-negotiable. They allow your suspension to achieve its full intended articulation without any restriction from the brake lines, maximizing traction and control on uneven terrain.

- Peace of Mind: Knowing that your braking system is properly configured for your lifted truck provides invaluable peace of mind, whether you’re navigating city streets or tackling a challenging trail.

Types of Extended Brake Hoses

When selecting extended brake hoses, you’ll generally encounter two main material types, each with its own characteristics:

-

DOT-Approved Rubber Hoses:

- Material: Similar to factory hoses, these are constructed from multiple layers of synthetic rubber reinforced with fabric braiding.

- Pros: Cost-effective, good flexibility, generally quiet, and provide a comfortable pedal feel. They meet Department of Transportation (DOT) safety standards.

- Cons: Can be susceptible to expansion under extreme pressure (leading to a slightly "softer" pedal feel compared to stainless steel), and over time, UV exposure and environmental factors can degrade the rubber.

-

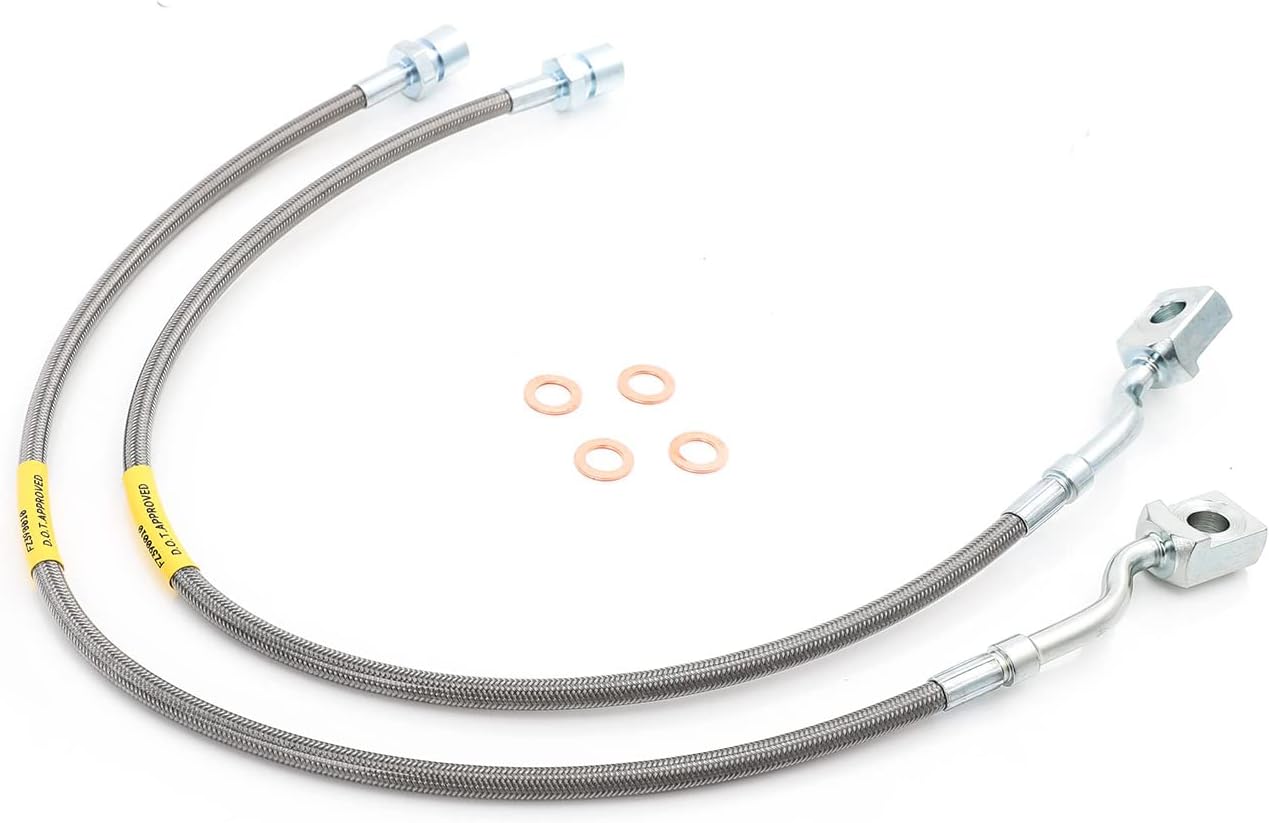

Braided Stainless Steel (PTFE/Teflon Core) Hoses:

- Material: These hoses feature a PTFE (Teflon) inner core, which is highly resistant to heat and chemicals, surrounded by a layer of stainless steel braiding, and often an outer PVC or urethane protective coating.

- Pros: Significantly stronger and more durable than rubber, highly resistant to expansion under pressure (resulting in a firmer, more consistent pedal feel), excellent resistance to abrasion, impact, and UV degradation. Often preferred for performance and heavy off-road use.

- Cons: Typically more expensive than rubber hoses, and some users might find the firmer pedal feel less "comfortable" initially.

For most lifted truck applications, especially those used for off-roading, braided stainless steel lines are often the preferred choice due to their superior durability and performance benefits. However, high-quality DOT-approved rubber hoses are perfectly adequate for many applications.

Choosing the Right Extended Brake Hoses: Key Considerations

Selecting the correct extended brake hoses for lifted trucks is paramount. Here’s what you need to consider:

- Determine the Correct Length: This is the most critical factor.

- Method 1 (Measurement): Jack up your truck until the suspension is at its absolute maximum droop (wheels hanging freely). Measure the distance from your hard brake line connection point on the chassis to the caliper/wheel cylinder, accounting for the path the hose will take. Add an additional 1-2 inches for slack and articulation.

- Method 2 (Lift Kit Recommendation): Many reputable lift kit manufacturers will specify the recommended extended brake hose length for their kits. Always refer to their guidelines.

- Account for Future Modifications: If you plan on adding longer shocks or modifying suspension components further, factor that into your length calculation.

- Material Choice: As discussed, decide between DOT-approved rubber or braided stainless steel based on your budget, driving style, and performance expectations.

- Correct Fittings: Ensure the new hoses come with the correct banjo bolts, crush washers, and line fittings (thread type and angle) to match your truck’s calipers/wheel cylinders and hard lines. Mismatched fittings will lead to leaks and system failure.

- DOT Approval: Always verify that the extended brake hoses are DOT (Department of Transportation) approved. This certification ensures they meet stringent safety and performance standards.

- Reputable Brand: Purchase from well-known and trusted manufacturers. This ensures quality materials, proper engineering, and reliable performance.

- Complete Kits: Many manufacturers offer complete extended brake line kits that include all necessary hoses (front and rear), banjo bolts, crush washers, and retention clips, simplifying the purchasing process.

Installation Guide: A Step-by-Step Overview

While this guide provides a general overview, if you’re not experienced with brake system work, it’s highly recommended to seek professional installation. Brake system integrity is non-negotiable for safety.

Tools and Materials:

- Jack and jack stands

- Wheel chocks

- Metric/SAE wrench set

- Flare nut wrenches (essential for brake line fittings to prevent rounding)

- Brake fluid (DOT 3 or DOT 4, as specified by your vehicle manufacturer)

- Brake bleeder kit (one-person bleeder, vacuum bleeder, or pressure bleeder)

- Drain pan for old brake fluid

- Shop rags/towels

- Gloves and eye protection

Steps:

- Safety First: Park on a level surface, engage the parking brake, and place wheel chocks. Jack up the truck and secure it firmly on jack stands. Remove the wheels.

- Prepare for Fluid Loss: Place a drain pan under the area where you’ll be disconnecting the brake lines. Have rags ready to catch drips.

- Disconnect Old Hoses: Using a flare nut wrench, carefully loosen the hard line fitting where it connects to the flexible brake hose. Then, disconnect the hose from the caliper/wheel cylinder and remove any retaining clips.

- Install New Hoses:

- Connect the new extended brake hose to the caliper/wheel cylinder, ensuring all banjo bolts and crush washers are correctly installed and torqued to manufacturer specifications.

- Route the hose carefully, ensuring it has adequate slack at full droop and compression, and that it doesn’t rub against any suspension components, frame, or tire. Use new retaining clips if provided.

- Connect the hard line to the new flexible hose fitting. Use a flare nut wrench and tighten securely, but do not overtighten, which can strip threads or crack lines.

- Repeat for All Wheels: Follow the same procedure for all brake hoses that require extension.

- Bleed the Brake System: This is a critical step. Air introduced into the brake lines during installation must be removed to restore proper brake function. Start with the wheel furthest from the master cylinder (typically rear passenger side), then rear driver, front passenger, and finally front driver. Follow your vehicle’s specific bleeding procedure, ensuring no air remains in the system.

- Inspect for Leaks: With the engine off, pump the brake pedal several times to build pressure. Hold the pedal down firmly and visually inspect all new connections for any signs of brake fluid leakage.

- Test Drive: Reinstall the wheels, lower the truck, and take it for a slow, controlled test drive in a safe area. Test the brakes gently at first, then gradually increase pressure, ensuring a firm pedal feel and effective stopping power. Listen for any unusual noises and re-check for leaks after the test drive.

Maintenance and Inspection Tips

Regular inspection of your extended brake hoses for lifted trucks is crucial for ongoing safety:

- Visual Checks: Periodically inspect the entire length of each hose for cracks, bulges, chafing, cuts, or signs of fluid leakage.

- Fittings: Ensure all fittings are tight and free from corrosion.

- Routing: Confirm that hoses are still routed correctly and aren’t rubbing against anything. Re-secure any loose clips or ties.

- Post-Off-Road Inspection: After any particularly demanding off-road excursions, give your brake lines a thorough inspection for impact damage or snags.

- Fluid Level: Regularly check your brake fluid reservoir level. A consistently low level could indicate a slow leak.

Common Challenges and Solutions

- Incorrect Hose Length:

- Challenge: Hoses are too short (stress at droop) or too long (chafing, snagging).

- Solution: Meticulous measurement is key. Always re-measure if unsure, and if necessary, order a replacement of the correct length.

- Improper Routing:

- Challenge: Hoses rubbing against tires, suspension components, or frame, leading to premature wear.

- Solution: Take your time during installation. Cycle the suspension through its full travel (if possible on a lift) to observe hose movement. Use zip ties or P-clips to secure hoses away from potential rub points, ensuring they still have enough slack.

- Air in the Brake System:

- Challenge: Spongy brake pedal, reduced braking effectiveness.

- Solution: Thorough and correct bleeding of the entire brake system. Sometimes, a vacuum bleeder or pressure bleeder is more effective than traditional two-person methods.

- Leaking Fittings:

- Challenge: Brake fluid leaks at connection points.

- Solution: Ensure fittings are properly torqued (not overtightened), crush washers are new and correctly seated, and threads are not cross-threaded.

Extended Brake Hoses for Lifted Trucks: Price Table

The price of extended brake hoses can vary significantly based on material, length, brand, and whether they are purchased individually or as a complete kit. Here’s an estimated price table:

| Type of Hose | Material | Length Range (Lift Height) | Typical Price Range (USD) | Key Features | Common Brands |

|---|---|---|---|---|---|

| Basic Rubber (Pair) | DOT-Approved Rubber | 2" – 4" Lift | $40 – $80 | OEM-style flexibility, cost-effective, standard feel. | Crown, Omix-ADA, Dorman |

| Standard Stainless Steel (Pair) | Braided Stainless Steel (PTFE Core) | 2" – 6" Lift | $70 – $150 | Firmer pedal feel, increased durability, abrasion resistance. | Skyjacker, Rough Country, Fabtech |

| Premium Stainless Steel (Kit) | Braided Stainless Steel (PTFE Core) | 4" – 8"+ Lift | $150 – $350+ | Superior strength, ultimate durability, often includes all hardware, custom lengths. | Goodridge, Russell, StopTech, Synergy |

| Custom Length/Application | Braided Stainless Steel (PTFE Core) | Variable | $80 – $150+ (per hose) | Tailored to extreme lift/articulation needs, specific fittings. | Individual fabricators, specialty shops |

Note: Prices are estimates and can vary based on vehicle make/model, retailer, and specific kit contents. Always confirm DOT approval.

Frequently Asked Questions (FAQ)

Q: Do I really need extended brake hoses for my lifted truck?

A: Absolutely. If your truck has any suspension lift that increases the distance between your chassis and axles, extended brake hoses are a critical safety component to prevent hose stretching, damage, and potential brake failure, especially during suspension articulation.

Q: How do I know what length of extended brake hose to get?

A: The most accurate way is to measure at full suspension droop (with the wheel hanging freely). Measure from the hard line connection to the caliper, following the intended hose path, and add 1-2 inches for slack. Alternatively, consult your lift kit manufacturer’s recommendations.

Q: Can I install extended brake hoses myself?

A: If you have experience working with brake systems, understand proper bleeding procedures, and have the correct tools (especially flare nut wrenches), it’s possible. However, due to the critical safety nature of brakes, if you are unsure, professional installation is strongly recommended.

Q: What’s the difference between rubber and stainless steel extended brake hoses?

A: Rubber hoses are more flexible and cost-effective, offering an OEM-like feel. Stainless steel braided hoses are more durable, resistant to expansion under pressure (providing a firmer pedal), and offer superior protection against abrasion and UV degradation.

Q: Are all extended brake hoses DOT approved?

A: No, not all. It is crucial to verify that any extended brake hoses you purchase are DOT (Department of Transportation) approved. This certification ensures they meet essential safety and performance standards.

Q: Do I need to bleed my brakes after installing extended brake hoses?

A: Yes, absolutely. Any time you open the brake system, air will be introduced. Thoroughly bleeding the entire brake system is mandatory to remove all air and restore proper braking function.

Conclusion

Upgrading to extended brake hoses for lifted trucks is a non-negotiable step for anyone modifying their vehicle’s suspension. It’s a critical safety measure that ensures your braking system can handle the increased suspension travel and articulation without compromise. By understanding the types, choosing the correct length and material, and performing a careful installation and regular maintenance, you ensure not only optimal braking performance but also peace of mind, allowing you to enjoy your lifted truck safely on any adventure. Don’t overlook this vital component – your safety depends on it.