DOT Lighting Requirements for Trucks: Illuminating the Path to Safety and Compliance

DOT Lighting Requirements for Trucks: Illuminating the Path to Safety and Compliance

In the vast and complex world of commercial trucking, safety is paramount. Every component of a heavy-duty vehicle plays a critical role in ensuring the well-being of the driver, other motorists, and the cargo being transported. Among these vital components, the lighting system stands out as a fundamental element of safety and regulatory compliance. The DOT lighting requirements for trucks, enforced by the Department of Transportation, are not merely suggestions; they are stringent regulations designed to ensure maximum visibility and clear communication on the road, day or night, and in all weather conditions.

Understanding and adhering to these DOT lighting requirements for trucks is not just about avoiding fines; it’s about preventing accidents, saving lives, and maintaining the operational integrity of a trucking business. This comprehensive guide will delve into the intricacies of these regulations, providing a clear, actionable understanding for truck owners, operators, and drivers alike.

I. The Foundation of Safety: Why DOT Lighting Matters

The primary purpose of DOT lighting requirements for trucks is to enhance visibility and communication, thereby significantly reducing the risk of accidents. A truck, especially a combination vehicle, is a massive presence on the road. Without proper illumination, its size, speed, and intentions (stopping, turning, changing lanes) can be dangerously obscured, particularly in low-light conditions, adverse weather, or busy traffic.

- Accident Prevention: Properly functioning and compliant lights allow other drivers to see the truck from a distance, accurately judge its size, and understand its maneuvers. This early warning system is crucial for preventing rear-end collisions, side swipes, and head-on accidents.

- Driver and Public Safety: By making the truck more conspicuous, lights protect the truck driver by reducing the likelihood of other vehicles colliding with them. They also protect the general public by ensuring that the truck’s presence and actions are clearly communicated.

- Legal and Financial Implications: Non-compliance with DOT lighting requirements for trucks can lead to severe consequences. These include hefty fines, out-of-service orders (which mean lost revenue), increased insurance premiums, and potential liability in the event of an accident. Furthermore, a poor safety record can negatively impact a carrier’s CSA (Compliance, Safety, Accountability) score, leading to more frequent inspections and scrutiny.

II. Core Lighting Requirements: What Every Truck Needs

At the heart of DOT lighting requirements for trucks are the fundamental lights necessary for basic vehicle operation and safety. These apply to virtually all motor vehicles, with specific standards for commercial trucks.

- Headlights: Essential for illuminating the road ahead. Trucks must have two white headlights, one on each side of the front. They must include both low and high beam settings, adequately illuminating the road without blinding oncoming drivers. Proper aiming is crucial.

- Taillights: Two red taillights are required at the rear of the truck, one on each side. They must be visible from a specified distance (typically 500 feet) and remain illuminated when the headlights are on, signaling the vehicle’s presence.

- Brake Lights (Stop Lamps): Also known as stop lights, these must be two red lights at the rear, one on each side. They must illuminate brighter than the taillights when the brake pedal is pressed, clearly indicating that the truck is slowing down or stopping.

- Turn Signals (Directional Signals): Both front and rear turn signals are mandatory. Front signals must be amber, while rear signals can be either amber or red. They must flash distinctly and synchronously when activated, signaling an intended turn or lane change.

- Hazard Warning Lights (Four-Way Flashers): This system activates all turn signals simultaneously, indicating a disabled vehicle or a hazard on the road. They are crucial for safety during breakdowns or emergency stops.

- License Plate Light: A white light illuminating the rear license plate is required, making the plate legible from a distance of 50 feet at night.

- Reflectors: Passive safety devices, reflectors do not require power but bounce light back. Red reflectors are required at the rear, and amber reflectors along the sides. They provide visibility even if electrical power fails.

III. Specialized Lighting for Commercial Vehicles

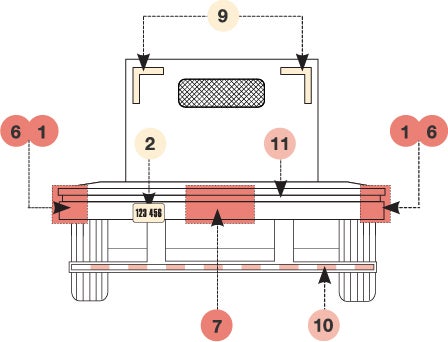

Beyond the basic requirements, DOT lighting requirements for trucks include specific provisions for the unique dimensions and operational needs of commercial vehicles, particularly those exceeding certain lengths or widths.

- Clearance Lights: These lights indicate the extreme width and height of the truck. They must be amber on the front (two) and red on the rear (two), mounted as high and wide as practicable. They ensure other drivers recognize the full dimensions of the truck, especially in low light.

- Identification Lights: Often seen on the top center of the front and rear of the cab or trailer, these consist of three amber lights (front) or three red lights (rear), spaced 6 to 12 inches apart. They signify that the vehicle is 80 inches or more in width.

- Side Marker Lights: Amber side marker lights are required along the sides of trailers and long trucks, typically at intervals of 25 feet or less. They provide continuous indication of the vehicle’s length, crucial for safe passing and maneuvering.

- Conspicuity Tape (Reflective Sheeting): A vital passive safety measure, conspicuity tape is highly reflective material applied to the sides and rear of trailers and long trucks. It must be alternating red and white, covering at least 50% of the length of the sides and across the entire lower bar of the rear. This dramatically increases visibility, especially at night or in poor weather.

- Work Lights/Auxiliary Lights: While not always strictly DOT-mandated for driving, auxiliary lights (like fog lights, spotlights, or work lights) have specific rules. They must not interfere with the visibility of required lights, nor can they be activated in a way that blinds other drivers. Generally, white or amber are acceptable colors, and they must be switched off when on public roads if they create glare.

IV. Color, Placement, and Visibility: Key Considerations

Adherence to DOT lighting requirements for trucks extends beyond merely having the correct lights; it dictates their color, precise placement, and the distance from which they must be visible.

- Color Requirements:

- White: Headlights, reverse lights, license plate light.

- Amber (Yellow): Front turn signals, side marker lights, front clearance lights, front identification lights, auxiliary lights (if applicable).

- Red: Taillights, brake lights, rear turn signals (optional, if not amber), rear clearance lights, rear identification lights, rear reflectors.

- Placement Rules: Lights must be symmetrically placed on the vehicle. There are specific height requirements (e.g., brake lights between 15 and 72 inches from the ground) and width requirements (e.g., clearance lights marking the widest points). Lights must not be obstructed by cargo, mud flaps, or other vehicle components.

- Visibility Standards: Each type of light has a minimum distance from which it must be clearly visible. For instance, headlights and taillights are typically required to be visible from 500 feet, while brake lights often require visibility from 300 feet in daylight. Reflectors must be effective from 100 to 600 feet when illuminated by high beams.

- Maintenance & Inspection: Even the best lights are useless if they don’t work. Regular cleaning of lenses, checking for cracked or broken housings, and prompt replacement of burned-out bulbs are critical. Modern LED lighting systems offer greater durability and longevity, reducing maintenance frequency but not eliminating the need for checks.

V. Practical Advice for Compliance and Maintenance

Achieving and maintaining full compliance with DOT lighting requirements for trucks is an ongoing process that requires diligence and a proactive approach.

- Regular Pre-Trip and Post-Trip Inspections: Incorporate a thorough check of all lights into your daily pre-trip and post-trip inspection routines. This includes walking around the entire vehicle, checking headlights, turn signals (front and rear), brake lights (with assistance or by backing up to a wall), clearance lights, marker lights, and identification lights. Don’t forget the license plate light and conspicuity tape.

- Use Quality, DOT-Approved Lights: Invest in lighting components that explicitly state "DOT approved" or meet FMVSS (Federal Motor Vehicle Safety Standards) 108. Cheap, non-compliant lights may fail prematurely or not meet the required brightness and visibility standards.

- Understand State-Specific Variations: While federal DOT regulations set a baseline, individual states may have additional or more stringent requirements. Always be aware of the specific regulations in the states you operate in. For example, some states may have different rules for flashing lights or auxiliary lighting.

- Documentation and Record-Keeping: Maintain records of light inspections, maintenance, and repairs. This documentation can be invaluable during roadside inspections or in the event of an accident, demonstrating a commitment to safety and compliance.

- Train Drivers: Ensure all drivers are thoroughly trained on the importance of lighting, how to perform proper light checks, and what to do if a light malfunctions on the road. Empowering drivers to identify and report issues immediately is key.

VI. Challenges and Solutions in Maintaining Compliance

Despite the clear guidelines, maintaining perfect lighting compliance can present challenges due to the harsh operating environment of commercial trucks.

- Vibration Damage: Constant vibration can loosen connections, damage filaments (in incandescent bulbs), and crack housings.

- Solution: Upgrade to LED lights, which are more resistant to vibration. Use robust, vibration-dampening mounts and ensure all wiring connections are secure and properly insulated.

- Weather Exposure: Rain, snow, ice, and road salt can cause corrosion, short circuits, and reduced visibility due to dirt accumulation.

- Solution: Opt for sealed lighting units with high IP (Ingress Protection) ratings. Regularly clean light lenses and check for water ingress. Apply dielectric grease to electrical connections.

- Electrical Issues: Fuses blowing, faulty wiring, or poor grounds can lead to intermittent or complete light failure.

- Solution: Implement a preventive maintenance schedule for the entire electrical system. Use proper gauge wiring, secure all ground connections, and promptly address any flickering or dim lights.

- Impact Damage: Lights are susceptible to damage from minor impacts, road debris, or loading/unloading operations.

- Solution: Install lights in protected areas where possible. Consider using robust, impact-resistant light housings or guards.

Summary Table of Key DOT Lighting Requirements for Trucks

| Light Type | Required Color | Minimum Quantity (per vehicle/trailer) | Typical Placement | Key Function / Notes |

|---|---|---|---|---|

| Headlights | White | 2 (1 pair) | Front, symmetrical | Illuminate road ahead (low & high beam). Must not blind oncoming traffic. |

| Taillights | Red | 2 (1 pair) | Rear, symmetrical | Indicate presence of vehicle from rear. Visible from 500 ft. |

| Brake Lights | Red | 2 (1 pair) | Rear, symmetrical (brighter than taillights) | Indicate braking/slowing. Visible from 300 ft (daylight). |

| Turn Signals (Front) | Amber | 2 (1 pair) | Front, symmetrical | Indicate intended turn/lane change. |

| Turn Signals (Rear) | Amber or Red | 2 (1 pair) | Rear, symmetrical | Indicate intended turn/lane change. |

| Hazard Lights | Amber or Red | All turn signals activated simultaneously | All turn signal locations | Indicate disabled vehicle or hazard. |

| License Plate Light | White | 1 | Rear, illuminating license plate | Make license plate legible from 50 ft at night. |

| Rear Reflectors | Red | 2 | Rear, symmetrical | Passive visibility, effective from 100-600 ft. |

| Side Reflectors | Amber | As needed | Along sides of vehicle/trailer (typically every 25 ft) | Passive visibility along vehicle length. |

| Clearance Lights | Amber (Front), Red (Rear) | 4 (2 front, 2 rear) | Top corners, widest/highest points | Indicate extreme width/height of vehicle (for vehicles over 80" wide). |

| Identification Lights | Amber (Front), Red (Rear) | 6 (3 front, 3 rear) | Top center, 6-12" apart | Indicate vehicle is 80" or more wide. |

| Side Marker Lights | Amber | As needed | Along sides of vehicle/trailer (typically every 25 ft) | Indicate full length of vehicle/trailer. |

| Conspicuity Tape | Red & White (Alternating) | As needed | Sides and rear of trailers/long trucks | Highly reflective, enhances visibility (especially at night). Covers at least 50% of length on sides, full width on rear. |

Frequently Asked Questions (FAQ) about DOT Lighting Requirements for Trucks

Q1: Can I use LED lights instead of traditional incandescent bulbs?

A1: Yes, absolutely! LED lights are fully compliant with DOT lighting requirements for trucks as long as they meet the required brightness, color, and visibility standards set by FMVSS 108. In fact, LEDs are often preferred due to their longer lifespan, lower power consumption, and greater resistance to vibration.

Q2: Are auxiliary lights, like fog lights or off-road lights, allowed?

A2: Auxiliary lights are generally permitted, but they must adhere to specific rules. They cannot interfere with the visibility or operation of required DOT lights, must be the correct color (usually white or amber), and often have restrictions on when they can be used on public roads (e.g., fog lights only in inclement weather, off-road lights only when off-road). They must also not create excessive glare for other drivers.

Q3: What are the consequences of non-compliance with DOT lighting requirements?

A3: Non-compliance can lead to severe penalties, including fines ranging from hundreds to thousands of dollars, out-of-service orders (meaning the truck cannot operate until repairs are made), negative impacts on a carrier’s CSA score, and increased liability in the event of an accident. Repeat offenses can lead to more severe penalties and even suspension of operating authority.

Q4: How often should I check my truck’s lights?

A4: All lights should be checked during the mandatory pre-trip inspection before every journey. A quick check during the post-trip inspection is also highly recommended. For long-haul operations, it’s wise to perform a quick visual check during fuel stops or rest breaks.

Q5: Do state laws differ from federal DOT lighting requirements?

A5: Federal DOT regulations (specifically FMVSS 108) set the minimum standard for all commercial vehicles operating in the U.S. While states cannot enforce less stringent rules, they can, and sometimes do, impose additional or more specific requirements (e.g., regarding flashing lights, additional auxiliary lights, or specific light aiming standards). It’s crucial for drivers and carriers to be aware of the laws in all states they operate within.

Conclusion

The DOT lighting requirements for trucks are a cornerstone of road safety in the commercial trucking industry. Far from being a mere bureaucratic hurdle, these regulations are meticulously designed to ensure that every large vehicle on our highways is highly visible and communicates its intentions clearly to everyone around it.

For truck owners, operators, and drivers, a thorough understanding and unwavering commitment to these requirements are non-negotiable. Proactive maintenance, regular inspections, and investing in quality, compliant lighting components are not just good practices; they are essential for protecting lives, safeguarding livelihoods, and ensuring the smooth, safe flow of commerce across the nation. By illuminating the path, trucks can continue to be the backbone of our economy, safely and reliably.