The Unsung Hero: A Comprehensive Guide to Semi Truck Light Cords

The Unsung Hero: A Comprehensive Guide to Semi Truck Light Cords

In the intricate dance of a semi-truck and its trailer, countless components work in unison to ensure safe and efficient transit. Among these, often overlooked but critically important, is the semi truck light cord. More than just a bundle of wires, this unassuming cable serves as the vital nervous system, transmitting essential electrical signals between the tractor and the trailer. Without a reliable light cord, a semi-truck becomes a hazard on the road, incapable of signaling its intentions, illuminating its presence, or ensuring the proper function of critical safety systems like Anti-lock Braking Systems (ABS).

This comprehensive guide will delve deep into the world of semi-truck light cords, exploring their anatomy, critical importance, various types, installation best practices, common issues, and essential maintenance tips. Whether you’re a seasoned truck driver, a fleet manager, or simply curious about the mechanics of these behemoths, understanding the light cord is fundamental to appreciating the safety and operational integrity of commercial trucking.

The Anatomy of a Semi Truck Light Cord: More Than Meets the Eye

At its core, a semi-truck light cord is an electrical conduit, designed to carry power and data between the tractor’s electrical system and the trailer’s various lights and components. The most common configuration is the 7-pin J560 connector, which has become the industry standard for its robust design and comprehensive signal transmission capabilities.

Let’s break down its key components:

- The Cable Itself: This is the flexible backbone, typically made of durable PVC or rubberized material designed to withstand harsh weather, abrasion, and constant flexing. Inside, it houses multiple insulated copper wires.

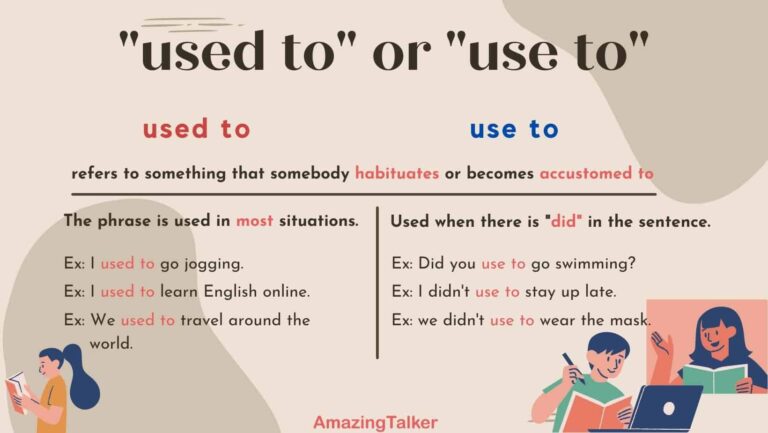

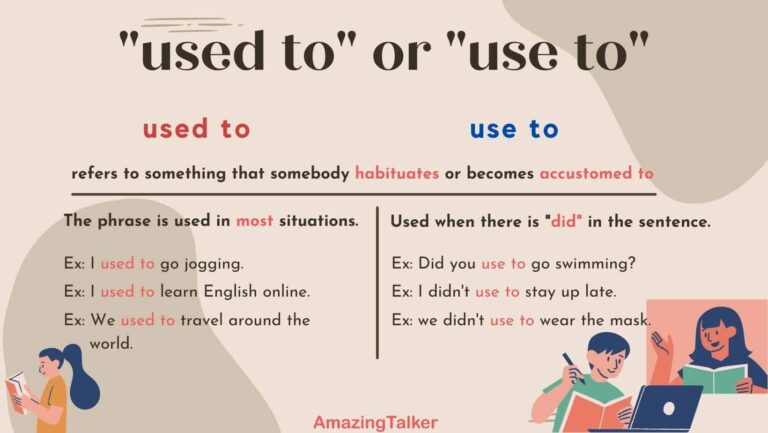

- The 7-Pin Connector (Plug): This is the business end that plugs into the corresponding receptacle on the tractor and trailer. Each of the seven pins serves a specific function, adhering to a standardized wiring diagram (J560 standard):

- Pin 1 (White): Ground (provides return path for current).

- Pin 2 (Black): Auxiliary Power / Reverse Lights (can be used for various auxiliary functions).

- Pin 3 (Yellow): Left Turn Signal / Stop Light.

- Pin 4 (Red): Constant Power / Trailer Brakes (for electric brakes).

- Pin 5 (Green): Right Turn Signal / Stop Light.

- Pin 6 (Brown): Tail Lights / Marker Lights / Clearance Lights.

- Pin 7 (Blue): ABS Warning Light / Electric Brake Control (often dedicated to ABS communication).

- The Housing/Jacket: This outer layer protects the internal wires from physical damage, moisture, UV radiation, and chemicals encountered on the road. High-quality jackets are crucial for longevity.

- Wire Conductors: Each pin connects to a specific wire, typically color-coded according to the J560 standard, ensuring proper signal transmission. The gauge (thickness) of these wires is important for handling the required current without overheating.

Understanding these components is the first step in appreciating the cord’s functionality and diagnosing potential issues.

Why the Light Cord is So Crucial: Safety, Compliance, and Efficiency

The semi-truck light cord isn’t just a convenience; it’s a critical safety device and a legal necessity. Its importance cannot be overstated for several reasons:

-

Road Safety: This is paramount. The light cord powers all the trailer’s external lights:

- Tail Lights: Make the trailer visible from behind, especially at night or in low visibility.

- Brake Lights: Indicate when the truck is slowing down or stopping, preventing rear-end collisions.

- Turn Signals: Communicate lane changes or turns, essential for maneuvering such a large vehicle.

- Marker/Clearance Lights: Define the trailer’s dimensions, particularly its width and height, crucial for other drivers to gauge safe passing distance.

- ABS Communication: For trailers equipped with ABS, the cord transmits vital data, ensuring the trailer’s brakes function correctly and preventing wheel lock-up during hard braking. This significantly reduces the risk of jackknifing.

-

Legal Compliance: Department of Transportation (DOT) regulations and state laws strictly mandate operational lighting systems on commercial vehicles. A non-functional light cord, leading to inoperable lights, can result in hefty fines, out-of-service orders, and costly delays. Regular pre-trip inspections, including checking all lights, are a legal requirement.

-

Operational Efficiency: Beyond safety and legality, a reliable light cord contributes to smooth operations. Downtime due to electrical issues or fines for non-compliance can significantly impact a trucking business’s profitability. A well-maintained cord ensures consistent performance, reduces the likelihood of roadside breakdowns, and keeps schedules on track.

-

System Integration: The cord facilitates communication beyond just lights. It can supply auxiliary power for features like liftgates, interior lights, or other trailer-specific electrical components, making it a versatile conduit for various trailer functions.

Types of Semi Truck Light Cords: Matching the Cord to the Haul

While the 7-pin J560 connector is standard, the physical form and material of the light cord can vary significantly, each designed for specific applications and environments.

-

Straight Cords:

- Description: A simple, straight length of cable, often used for shorter connections or specific setups where a coiled cord might snag.

- Pros: Generally less expensive, straightforward design.

- Cons: Can sag, drag on the ground, or get tangled if not properly secured, leading to premature wear and tear.

- Best Use: Applications where minimal slack is needed and the cord can be securely fastened to prevent dragging.

-

Coiled (Spiral) Cords:

- Description: The most common type, featuring a spiral shape that allows the cord to expand and contract with the movement of the truck and trailer.

- Pros: Naturally retracts, minimizing sag and preventing dragging, reduces tangling, provides flexibility for tight turns.

- Cons: Can sometimes become stiff in extreme cold, and the coils can collect dirt or ice.

- Best Use: Standard over-the-road trucking, where flexibility and self-retraction are highly valued. Available in various lengths to accommodate different tractor-trailer gap distances.

-

Heavy-Duty / Reinforced Cords:

- Description: Feature thicker insulation, stronger connectors, and sometimes additional strain relief. Often made with more robust materials like high-grade rubber or polyurethane.

- Pros: Superior durability, resistance to abrasion, chemicals, and extreme temperatures; longer lifespan in demanding conditions.

- Cons: Higher upfront cost, can be less flexible than standard cords.

- Best Use: Off-road applications, construction sites, refuse hauling, or any environment where the cord is exposed to severe abuse or extreme weather.

-

ABS-Specific Cords:

- Description: While all 7-pin cords can carry the ABS signal (Pin 7), some cords are specifically designed with enhanced shielding or higher-quality conductors to ensure flawless ABS communication, which is critical for safety.

- Pros: Optimized for reliable ABS data transmission.

- Cons: May be slightly more expensive.

- Best Use: Modern trailers equipped with advanced ABS and electronic braking systems.

Choosing the right type depends on the operating environment, the specific trailer requirements, and the desired lifespan and reliability.

Installation and Connection: A Step-by-Step Guide

Connecting a semi-truck light cord might seem straightforward, but proper technique ensures reliability and prevents damage.

- Inspect Both Receptacles: Before connecting, visually inspect the 7-pin receptacles on both the tractor and trailer. Look for dirt, corrosion, bent pins, or signs of damage. Clean them if necessary using a wire brush or electrical contact cleaner.

- Align the Plugs: The J560 7-pin connectors are keyed, meaning they can only be inserted in one orientation. Align the notch on the cord’s plug with the corresponding keyway on the receptacle.

- Push and Twist (if applicable): For some connectors, a firm push is sufficient. Others require a slight twist (clockwise) to lock them securely in place. Ensure it feels snug and doesn’t wiggle.

- Secure the Cord:

- Coiled Cords: Allow the cord to hang freely between the tractor and trailer, ensuring it has enough slack for turns but not so much that it sags excessively or risks dragging. Use the pogo stick or hanger if available to keep it elevated.

- Straight Cords: These must be properly routed and secured using cable ties or hangers to prevent them from dragging on the ground, getting pinched, or coming into contact with moving parts.

- Test All Lights: This is a crucial final step. With the truck running and the cord connected:

- Activate the left turn signal.

- Activate the right turn signal.

- Turn on the headlights (checking tail, marker, and clearance lights).

- Press the brake pedal (checking brake lights).

- If equipped, check reverse lights.

- Verify the ABS warning light on the dash goes out after a self-test, indicating proper ABS communication.

- Have a helper or use a reflective surface to confirm all lights are functioning correctly on the trailer.

Common Problems and Troubleshooting: Keeping the Lights On

Even the most robust light cords can encounter issues. Knowing how to identify and troubleshoot common problems can save time, money, and prevent safety hazards.

- Corrosion: The most frequent culprit. Moisture, road salt, and dirt can cause oxidation on the pins and inside the receptacle, leading to poor electrical contact.

- Solution: Regular cleaning with a wire brush or sandpaper (for pins) and electrical contact cleaner. Apply dielectric grease to the pins to prevent future corrosion.

- Frayed Wires / Damaged Insulation: Constant flexing, rubbing, or pinching can wear through the outer jacket, exposing the internal wires. This can lead to shorts or complete circuit breaks.

- Solution: Visual inspection during pre-trip. Small, isolated damage might be repaired with electrical tape or heat shrink, but extensive damage warrants cord replacement.

- Loose Connections: Vibrations and improper installation can cause the plug to come loose from the receptacle, leading to intermittent light function.

- Solution: Ensure a firm, secure connection. Check the locking mechanism on the plug.

- Bent or Broken Pins: Rough handling or improper insertion can bend or break pins, preventing specific signals from transmitting.

- Solution: Carefully attempt to straighten bent pins with needle-nose pliers (if possible without breaking). Broken pins usually require cord replacement or connector repair.

- No Power to Trailer (All Lights Out):

- Troubleshooting: Check the truck’s fuses related to trailer power. Inspect the ground wire (Pin 1) for a secure connection. Test voltage at the truck’s receptacle.

- Specific Light Not Working:

- Troubleshooting: Identify the pin for that specific light (e.g., Pin 3 for left turn). Check the corresponding wire on the cord for continuity. Inspect the bulb on the trailer. Check the trailer’s internal wiring and fuses for that light circuit.

- Flickering Lights: Often indicates a loose connection, partial corrosion, or a compromised wire.

- Troubleshooting: Wiggle the cord at the connection point. Clean and apply dielectric grease. Inspect the cord for internal breaks (flexing it might reveal the issue).

For more complex electrical issues, a multimeter is an invaluable tool for testing continuity and voltage at various points in the circuit.

Maintenance and Longevity: Extending Your Cord’s Lifespan

Proactive maintenance is key to maximizing the lifespan of your semi-truck light cord and ensuring reliable performance.

- Regular Inspections: Make inspecting the cord a part of your daily pre-trip routine. Look for cracks, abrasions, fraying, kinks, and signs of corrosion on the plugs.

- Keep it Clean: Regularly clean the pins and inside the receptacle with a non-abrasive brush and electrical contact cleaner. Road grime, salt, and moisture are enemies of electrical connections.

- Apply Dielectric Grease: After cleaning, apply a thin layer of dielectric grease to the pins of both the cord and the receptacle. This silicone-based grease repels moisture, prevents corrosion, and improves electrical conductivity without conducting electricity itself.

- Proper Handling:

- Avoid Dragging: Never let the cord drag on the ground. This causes rapid abrasion and damage to the outer jacket.

- Prevent Kinking: Avoid sharp bends or kinks, especially near the connectors, as this can break internal wires.

- Don’t Overstretch: Ensure the cord (especially coiled ones) has sufficient length for all turning angles without being pulled taut.

- Secure Mounting: Ensure any pogo sticks or hangers used to support coiled cords are in good condition and positioned correctly to prevent excessive sag.

- Store Properly: If you remove the cord or have spares, coil them neatly and store them in a clean, dry place, away from extreme temperatures or sharp objects.

- Replace When Necessary: While minor repairs are possible, a severely damaged or extensively corroded cord should be replaced. The cost of a new cord is minimal compared to the potential fines, downtime, or, worse, an accident caused by faulty lighting.

Choosing the Right Light Cord: Important Considerations

Selecting the correct semi-truck light cord involves more than just picking the cheapest option. Consider these factors:

- Length: Ensure the cord is long enough to accommodate the maximum turning radius and the specific gap between your tractor and trailer, with sufficient slack. Too short, and it will be strained; too long, and it might drag.

- Material Quality: Look for cords made with high-quality, flexible materials like durable rubber or robust polyurethane. These offer better resistance to temperature extremes, abrasion, and chemicals than cheaper PVC alternatives.

- Connector Quality: The plugs themselves should be robust, with strong strain relief where the cable enters the plug. Metal housings are often more durable than plastic ones.

- Operating Environment: If you operate in harsh conditions (e.g., extreme cold, excessive road salt, construction sites), invest in a heavy-duty or reinforced cord.

- Brand Reputation: Stick with reputable brands known for producing quality truck parts. They often use better materials and adhere to stricter manufacturing standards.

- Budget vs. Quality: While cost is a factor, prioritizing a slightly more expensive, higher-quality cord often pays off in terms of longevity, reliability, and reduced maintenance.

Semi Truck Light Cord: Estimated Price Guide

Please note that prices can vary significantly based on brand, material quality, length, features, and supplier. This table provides estimated ranges for common types.

| Cord Type | Length Range (feet) | Material Type | Key Features | Estimated Price Range (USD) |

|---|---|---|---|---|

| Standard Straight Cord | 10 – 20 | PVC / Rubber | Basic 7-pin, general purpose | $20 – $50 |

| Standard Coiled Cord | 12 – 15 (working) | PVC / Rubber | Retracts, prevents dragging | $40 – $80 |

| Heavy-Duty Coiled Cord | 12 – 15 (working) | Rubber / Polyurethane | Thicker jacket, enhanced durability, cold-rated | $70 – $150 |

| ABS-Specific Coiled Cord | 12 – 15 (working) | Rubber / Polyurethane | Enhanced shielding for reliable ABS signals | $90 – $180 |

| Extended Length Coiled Cord | 20 – 25 (working) | Rubber / Polyurethane | For longer trailer combinations | $100 – $250 |

| Replacement 7-Pin Plug | N/A | Metal / Plastic | Individual plug for repair/replacement | $15 – $40 |

| Replacement 7-Pin Receptacle | N/A | Metal / Plastic | Trailer/Tractor side receptacle | $20 – $50 |

Note: Prices are estimates and subject to change. Always check with reputable suppliers for current pricing.

Frequently Asked Questions (FAQ)

Q1: How often should I inspect my semi-truck light cord?

A1: You should visually inspect your light cord as part of your daily pre-trip inspection. A more thorough inspection, including cleaning and applying dielectric grease, should be done weekly or monthly, depending on your operating conditions.

Q2: Can I repair a damaged light cord, or should I always replace it?

A2: Minor damage, like a small nick in the outer jacket away from the connectors, can sometimes be repaired with high-quality electrical tape or heat shrink. However, if there’s significant fraying, exposed wires near the connectors, bent/broken pins, or widespread cracking, it’s safer and more reliable to replace the entire cord.

Q3: What is dielectric grease used for, and how do I apply it?

A3: Dielectric grease is a silicone-based compound that repels moisture and prevents corrosion on electrical connections. It does not conduct electricity itself but improves contact by excluding contaminants. Apply a thin layer to the pins of both the cord and the receptacle after cleaning them.

Q4: What are the 7 pins for on a J560 connector?

A4: The 7 pins are standardized: Ground, Auxiliary/Reverse, Left Turn/Stop, Constant Power/Brakes, Right Turn/Stop, Tail/Marker/Clearance, and ABS Warning/Electric Brake Control.

Q5: Why do my trailer lights flicker intermittently?

A5: Flickering lights usually indicate a poor or intermittent connection. Common causes include corrosion on the pins, a loose plug, a partially frayed or broken wire inside the cord, or issues with the trailer’s grounding. Start by cleaning and securing the connection.

Q6: What’s the main difference between a straight and a coiled light cord?

A6: The main difference is flexibility and retraction. Coiled cords naturally expand and contract, preventing dragging and tangling. Straight cords are simpler but require careful routing and securing to avoid damage. Coiled cords are generally preferred for most over-the-road applications.

Q7: Are all 7-pin connectors the same?

A7: While the pin configuration (J560 standard) is the same, the quality of the connector housing and internal components can vary. Some are made of more durable materials (e.g., metal vs. plastic) and offer better weather sealing or strain relief.

Conclusion

The semi-truck light cord, though often out of sight and out of mind, is undeniably one of the most vital components connecting a tractor to its trailer. It is the silent workhorse that ensures visibility, enables critical safety systems like ABS, and keeps commercial vehicles compliant with strict road regulations. Neglecting this crucial link can lead to dangerous situations, costly fines, and unnecessary downtime.

By understanding its anatomy, recognizing its importance, performing diligent maintenance, and knowing when to replace it with a quality alternative, drivers and fleet managers can significantly enhance the safety, reliability, and efficiency of their operations. Investing in a high-quality light cord and adhering to best practices for its care is not just a matter of convenience; it’s an investment in safety on our roads.