The Essential Guide to Light Truck Tire Load Inflation Tables: Optimizing Performance, Safety, and Longevity

The Essential Guide to Light Truck Tire Load Inflation Tables: Optimizing Performance, Safety, and Longevity

In the world of light trucks, SUVs, and vans, where versatility often means carrying heavy loads, towing trailers, or navigating challenging terrain, tires are the unsung heroes. More specifically, the correct inflation of these tires is paramount to safety, performance, and the longevity of both the tires and the vehicle itself. This is where the Light Truck Tire Load Inflation Table becomes an indispensable tool.

A light truck tire load inflation table is a detailed chart, typically provided by tire manufacturers, that correlates specific tire sizes and types with the maximum load they can safely carry at various cold inflation pressures. Unlike the simplified tire pressure placard found on your vehicle’s door jamb (which typically indicates the minimum pressure for the vehicle’s Gross Vehicle Weight Rating or a lightly loaded condition), the load inflation table offers a dynamic guide. It empowers truck owners to precisely adjust their tire pressure based on the actual load being carried, ensuring optimal performance, preventing premature wear, and most critically, maintaining safety margins when operating at or near a truck’s maximum payload or towing capacity. Understanding and utilizing this table is not just about extending tire life; it’s about making informed decisions that directly impact the handling, stability, and overall safety of your light truck.

Understanding the Basics: What is a Load Inflation Table?

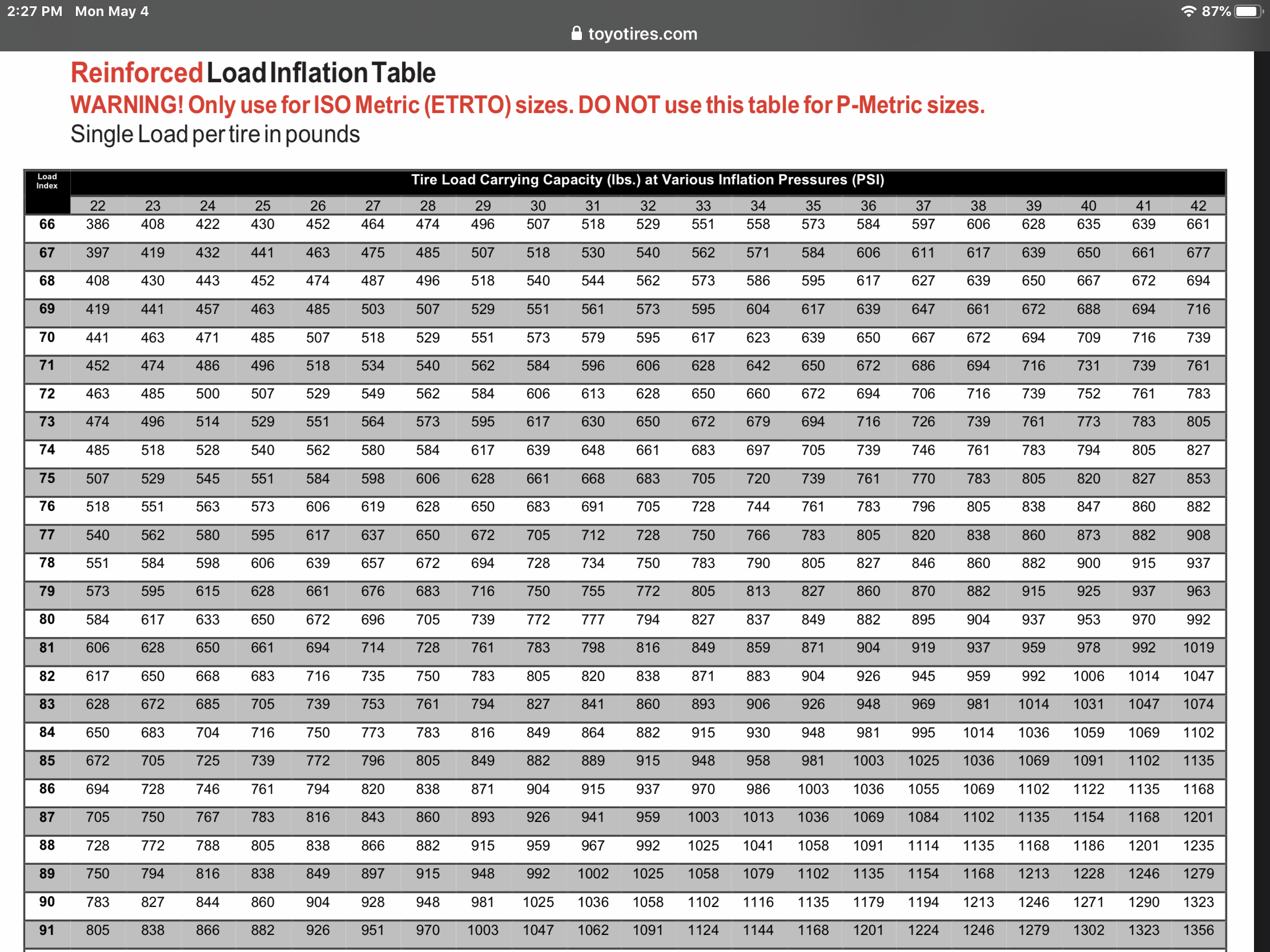

At its core, a light truck tire load inflation table is a data matrix. It typically lists a range of cold inflation pressures (in PSI or kPa) across the top row and corresponding load capacities (in pounds or kilograms) for specific tire sizes and load ranges in the columns below. These tables are developed based on extensive engineering, testing, and industry standards set by organizations like the Tire and Rim Association (TRA) in North America or the European Tyre and Rim Technical Organisation (ETRTO) in Europe.

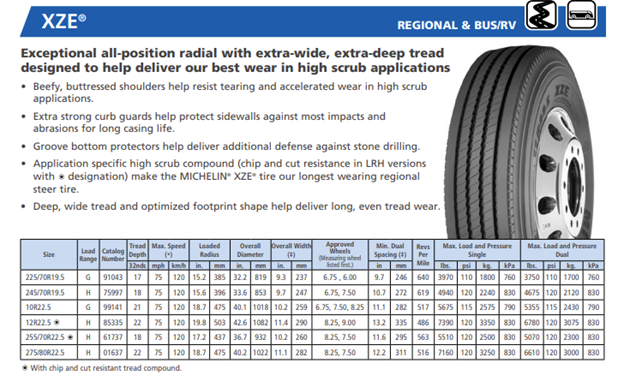

For instance, an LT-metric tire (e.g., LT265/75R16) or a flotation tire (e.g., 33×12.50R17LT) will have a specific load range (e.g., Load Range E, often signifying a 10-ply equivalent construction). The table will then show that at 35 PSI, this tire might support X pounds, but at 65 PSI, it can support Y pounds, and at its maximum rated pressure (e.g., 80 PSI for Load Range E), it can support its maximum rated load. Crucially, many tables also differentiate between single and dual applications, as tires used in a dual configuration (like on dually trucks) have a slightly reduced individual load capacity due to heat generation and load sharing.

It’s vital to distinguish this table from the tire’s sidewall information or the vehicle’s door placard. The tire sidewall lists the maximum cold inflation pressure and the maximum load capacity for that specific tire. The vehicle door placard provides the recommended minimum cold inflation pressure for the original equipment tires to achieve the vehicle’s Gross Vehicle Weight Rating (GVWR) under normal driving conditions. The load inflation table bridges the gap, allowing you to tailor pressure to your actual load, which can fluctuate significantly in a light truck.

Why Load Inflation Tables are Crucial for Light Trucks

The fluctuating nature of a light truck’s payload and towing demands makes the load inflation table indispensable. Here’s why:

- Enhanced Safety: Improper tire inflation is a leading cause of tire failure, which can lead to blowouts, loss of control, and accidents. Under-inflated tires generate excessive heat, increasing the risk of a blowout. Over-inflated tires reduce the contact patch with the road, leading to less traction, especially in braking and cornering, and can make the ride harsh. Using the table ensures tires are inflated to safely support the load, maintaining vehicle stability and handling.

- Optimized Performance: Correctly inflated tires provide the intended footprint on the road, distributing weight evenly across the tread. This results in predictable handling, improved steering response, and optimal braking performance.

- Extended Tire Longevity: Both under-inflation and over-inflation lead to uneven and accelerated tread wear. Under-inflation causes excessive wear on the outer edges of the tread, while over-inflation causes wear down the center. By matching pressure to load, you ensure even wear across the entire tread surface, maximizing the tire’s lifespan and saving you money on premature replacements.

- Improved Fuel Efficiency: Under-inflated tires have increased rolling resistance, meaning the engine has to work harder to move the vehicle. This directly translates to reduced fuel economy. Maintaining proper inflation according to the load helps minimize rolling resistance and optimize fuel consumption.

- Maximizing Payload & Towing Capacity: While you should never exceed your truck’s Gross Vehicle Weight Rating (GVWR) or Gross Combined Weight Rating (GCWR), understanding the load inflation table allows you to safely utilize your vehicle’s rated capacities. It ensures your tires can handle the weight you’re asking them to carry, preventing tire-related limitations from becoming a safety hazard.

Deciphering the Light Truck Tire Load Inflation Table: A How-To Guide

Using a load inflation table is straightforward once you understand its components.

- Locate Your Table: Tire manufacturers typically provide these tables on their websites, often in the technical specifications section for their light truck tires. You might also find general tables in industry publications like the TRA manual.

- Identify Your Tire Information: Note down your exact tire size (e.g., LT275/70R18) and its Load Range (e.g., E, D, C). This will help you find the correct row or section in the table.

- Determine Your Actual Load: This is the most critical step. You need to know the weight resting on your tires.

- Unloaded/Lightly Loaded: For everyday driving with minimal cargo, refer to your vehicle’s door jamb placard. This is the manufacturer’s recommended minimum for the truck’s GVWR.

- Loaded/Towing: Ideally, weigh your truck (and trailer, if applicable) at a public scale (like those at truck stops or landfills). Get individual axle weights if possible. If weighing isn’t feasible, accurately estimate your payload (cargo, passengers, tongue weight of a trailer).

- Consult the Table:

- Find your tire size and load range.

- Locate the column for your desired inflation pressure (or the closest increment).

- Read across to see the corresponding load capacity per tire.

- If you know your axle weight, divide that by two (for single axle applications) to get the load per tire. Find this load capacity in the table and then read up to find the minimum required pressure.

- Crucial Note for Dual Applications: If you have a dually truck, ensure you use the "Dual" load capacity column, as the capacity per tire is slightly reduced compared to a single application.

- Adjust and Monitor: Inflate your tires to the determined cold pressure. Always check pressure when tires are "cold" (driven less than a mile or sitting for at least three hours). Re-check periodically, especially before long trips or when changing loads.

Important Considerations and Practical Advice

- Vehicle Placard vs. Tire Sidewall vs. Load Table:

- Vehicle Placard: The minimum recommended pressure for your OEM tire size and vehicle GVWR, usually for unloaded or lightly loaded conditions. Always start here for baseline.

- Tire Sidewall: The maximum cold inflation pressure and corresponding maximum load the tire can carry. Never exceed this PSI.

- Load Inflation Table: The dynamic guide allowing you to adjust pressure between the placard minimum and the sidewall maximum, based on actual load.

- Never Exceed Axle Ratings: While the tire may be capable of carrying a certain load, you must never exceed your vehicle’s Gross Axle Weight Ratings (GAWR) or Gross Vehicle Weight Rating (GVWR) as specified by the vehicle manufacturer. The tires are just one component of the vehicle’s load-carrying system.

- Axle Weight Distribution: When towing or hauling, the rear axle typically bears a significantly higher load. It’s common to see higher inflation pressures recommended for rear tires than front tires in these scenarios.

- Temperature Effects: Tire pressure changes with temperature (approximately 1 PSI for every 10°F change). Check pressure when tires are cold. If you check them after driving, they will show a higher pressure due to heat buildup.

- Off-Roading: Load inflation tables are for on-road use. For serious off-roading, airing down is common to increase traction and ride comfort, but remember to re-inflate to appropriate on-road pressures before returning to pavement.

- Regular Checks: Tire pressure is not a set-it-and-forget-it parameter. Check your tire pressure at least once a month and always before a long trip or when you anticipate carrying a significant load. Invest in a good quality tire pressure gauge.

Challenges and Solutions

- Estimating Load: It’s often difficult to precisely know your vehicle’s weight without a scale.

- Solution: When in doubt, err on the side of slightly higher pressure (but never exceeding the tire’s max PSI or vehicle’s placard max for a given axle). Better yet, utilize public scales at truck stops or recycling centers to get accurate axle weights.

- Conflicting Information with Aftermarket Tires: If you’ve changed tire sizes or types from the OEM, the door placard may no longer be fully accurate for your new tires.

- Solution: Consult the tire manufacturer’s load inflation table for your specific aftermarket tires. However, still respect the vehicle manufacturer’s maximum axle weight ratings. A reputable tire shop can often help you determine appropriate pressures for your setup.

- Inconsistent Pressure Maintenance: It’s easy to forget to check pressures regularly.

- Solution: Make it a habit. Set a monthly reminder. Consider installing a Tire Pressure Monitoring System (TPMS) that provides real-time readings, especially beneficial for trailers.

Illustrative Example: Light Truck Tire Load Inflation Table (Conceptual)

This table demonstrates how load capacity changes with inflation pressure for a common LT tire size. This is a conceptual example; always refer to your specific tire manufacturer’s official table.

| Tire Size / Load Range | Max PSI (Cold) | Max Load (Single) LBS | Max Load (Dual) LBS | Load @ 35 PSI (LBS) | Load @ 45 PSI (LBS) | Load @ 65 PSI (LBS) | Load @ 80 PSI (LBS) |

|---|---|---|---|---|---|---|---|

| LT265/75R16 Load Range E | 80 | 3415 | 3030 | 2035 | 2420 | 3040 | 3415 |

| LT285/70R17 Load Range D | 65 | 3195 | 2835 | 2050 | 2425 | 3195 | N/A (Max 65 PSI) |

| LT245/75R17 Load Range E | 80 | 3195 | 2835 | 1910 | 2265 | 2840 | 3195 |

| 33×12.50R17LT Load Range C | 35 | 2535 | 2270 | 2535 | N/A (Max 35 PSI) | N/A | N/A |

Note: "N/A" indicates that the pressure exceeds the tire’s maximum recommended cold inflation pressure for that load range.

Frequently Asked Questions (FAQ)

Q1: Should I always inflate my LT tires to the maximum PSI listed on the sidewall?

A1: No. The maximum PSI on the sidewall is the pressure required to carry the tire’s maximum rated load. If you are driving an unloaded or lightly loaded truck, inflating to this maximum will result in a harsh ride, reduced traction, and premature wear in the center of the tread. Always refer to your vehicle’s door placard for minimum unloaded pressure, and use a load inflation table to adjust for actual loads.

Q2: My truck’s door sticker says 40 PSI, but my new LT tires say 80 PSI max. What should I do?

A2: For everyday driving with a light load, start with the 40 PSI indicated on your door placard. This pressure is optimized for your vehicle’s handling and ride quality in that condition. When you anticipate carrying heavy loads or towing, consult the load inflation table for your specific new tires. You will likely need to increase the pressure, potentially up to 65-80 PSI for the rear tires, to safely support the increased weight, but never exceed the 80 PSI maximum on the tire sidewall.

Q3: How often should I check my tire pressure?

A3: You should check your tire pressure at least once a month, and always before a long trip or whenever you plan to carry a significant load or tow a trailer. Check when the tires are cold.

Q4: What happens if I underinflate my LT tires?

A4: Under-inflation is extremely dangerous. It causes excessive heat buildup within the tire, which can lead to tread separation, tire failure, and blowouts. It also results in poor handling, increased rolling resistance (worse fuel economy), and premature wear on the outer edges of the tread.

Q5: What happens if I overinflate my LT tires?

A5: Over-inflation leads to a harsher ride, reduced tire contact patch with the road (which decreases traction and braking performance), and premature wear down the center of the tire’s tread. While generally less dangerous than severe under-inflation, it compromises safety and comfort.

Conclusion

The Light Truck Tire Load Inflation Table is far more than just a chart of numbers; it’s a critical safety and performance tool for any light truck owner. By understanding and actively using these tables, you gain the ability to precisely match your tire pressure to your vehicle’s demands, whether you’re commuting empty or hauling a maximum payload. This diligent approach not only enhances the safety and handling of your truck but also significantly extends the life of your tires, saving you money in the long run and ensuring you get the most out of your vehicle. Make regular pressure checks and intelligent use of your load inflation table a cornerstone of your light truck maintenance routine – it’s an investment in peace of mind and optimal performance.