Lights for Truck Tool Box: Illuminating Your Mobile Workshop

For anyone who relies on their truck tool box – be it a professional contractor, an avid DIYer, or an adventurous overlander – the struggle of fumbling for a specific wrench or a crucial screw in dimly lit conditions is all too familiar. Whether it’s dawn, dusk, or the dead of night, insufficient lighting can turn a simple task into a frustrating ordeal, costing valuable time and even posing safety risks. This is where lights for truck tool boxes come in, transforming a dark, cavernous space into a well-lit, organized, and highly efficient mobile workshop.

These specialized lighting solutions are designed to illuminate the interior of your truck tool box, ensuring that every tool, fastener, and piece of equipment is clearly visible. Far from being a mere luxury, integrating lights into your truck tool box is a practical upgrade that enhances visibility, improves efficiency, boosts safety, and adds a touch of professionalism to your mobile setup. This comprehensive guide will delve into the world of truck tool box lighting, covering everything from why you need them to how to choose, install, and maintain the perfect setup for your needs.

Why You Need Lights for Your Truck Tool Box

The benefits of illuminating your truck tool box extend far beyond simply seeing what’s inside. They contribute significantly to your productivity, safety, and overall convenience.

- Enhanced Visibility: This is the most obvious benefit. No more guessing games or relying on your phone’s flashlight. With proper lighting, every item in your tool box is instantly visible, regardless of ambient light conditions. This is invaluable when working early in the morning, late at night, in a dark garage, or on a remote job site.

- Increased Efficiency & Productivity: Time is money, and fumbling for tools wastes both. A well-lit tool box allows you to quickly locate and retrieve the exact item you need, minimizing downtime and maximizing your work output. This improved efficiency translates directly to higher productivity on any task.

- Improved Safety: Sharp tools, small parts, and unseen obstacles can lead to cuts, scrapes, or dropped items in the dark. Adequate lighting significantly reduces these risks by ensuring you have a clear view of your workspace and its contents, protecting both you and your equipment.

- Professionalism: A tidy, well-lit tool box reflects a professional who takes pride in their work and is prepared for any situation. It conveys an image of organization and readiness, which can leave a positive impression on clients or colleagues.

- Versatility: Whether you’re a plumber, electrician, carpenter, mechanic, or simply someone who frequently uses tools, the ability to access them quickly and safely in any lighting condition makes your work easier and more enjoyable.

Types of Lights for Truck Tool Boxes

The market offers a variety of lighting solutions, each with its own advantages, suited for different needs and preferences.

-

LED Strip Lights: These are arguably the most popular choice due to their versatility and efficiency.

- Pros: Highly flexible, can be cut to custom lengths to fit any tool box dimension, provide uniform illumination, very low power consumption, and long lifespan. Often come with adhesive backing for easy installation. Available in various brightness levels and color temperatures.

- Cons: Some require basic wiring if connecting to a 12V vehicle system. Not all are fully waterproof, so an IP67 rating is crucial for outdoor or moisture-prone environments.

- Installation: Typically peel-and-stick, often run along the underside of the lid or inside the box perimeter.

-

Puck Lights / Disk Lights: These are small, self-contained units that offer focused illumination.

- Pros: Compact, usually battery-powered (AA/AAA or rechargeable), extremely easy to install with adhesive or magnets, and good for spot lighting specific compartments.

- Cons: Provide less diffused light than strips, requiring multiple units for full coverage. Battery replacement can be frequent depending on usage.

- Installation: Simple peel-and-stick or magnetic attachment to any flat metal surface.

-

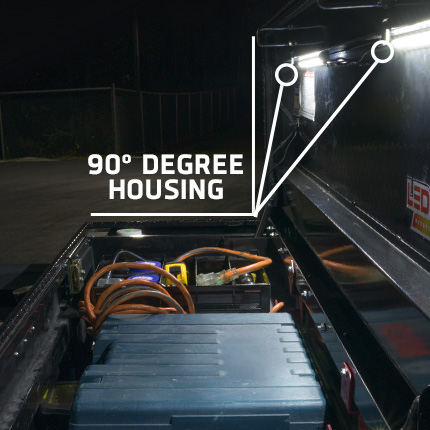

Under-Lid Lights (Integrated Systems): Some high-end tool boxes come with pre-installed lighting, or specific kits are designed to fit certain models.

- Pros: Seamless appearance, often designed for optimal fit and function, can be wired directly into the truck’s electrical system.

- Cons: Less flexible for custom layouts, may be more expensive or proprietary.

- Installation: Follow manufacturer’s instructions, usually straightforward.

-

Magnetic Lights: These are highly portable and repositionable lights, often incorporating LED technology.

- Pros: No permanent installation required, can be moved between different tool boxes or even used as a portable work light. Often rechargeable via USB.

- Cons: Can sometimes fall off if subjected to strong vibrations or if the magnet isn’t strong enough. Requires regular recharging.

- Installation: Simply attach to any ferrous metal surface.

-

Motion-Activated Lights: While not a distinct type of light, motion sensors are a common feature integrated into strip lights or puck lights.

- Pros: Hands-free operation – lights turn on automatically when the lid is opened or motion is detected, saving battery life.

- Cons: Can sometimes be triggered accidentally by vibrations or movement, and sensor reliability can vary.

Key Features and Considerations When Choosing Lights

Selecting the right lighting solution involves evaluating several crucial factors to ensure it meets your specific needs and the demanding environment of a truck tool box.

-

Power Source:

- Battery-Powered (AA/AAA, Lithium-ion Rechargeable): Offers maximum portability and ease of installation (no wiring). Ideal for those who don’t want to tap into their truck’s electrical system. Downsides include finite battery life, requiring replacements or regular recharging. Rechargeable options are more eco-friendly and cost-effective in the long run.

- 12V DC (Vehicle Power): Connects directly to your truck’s electrical system. Provides a constant, reliable power source without battery concerns. Requires more complex installation (wiring, fuses, switches) and careful management to avoid draining your truck battery if left on for extended periods.

-

Brightness (Lumens): Lumens measure the total amount of visible light emitted. For a tool box, you’ll want sufficient brightness to illuminate all corners without being blinding.

- Puck lights: Often range from 30-100 lumens per unit.

- LED strip lights: Can range from 200-1000+ lumens per meter, depending on the LED density and type. Consider the overall size of your tool box when determining the required lumen output.

-

Durability & Weatherproofing (IP Rating): Truck tool boxes are exposed to dust, dirt, moisture, and vibrations. An Ingress Protection (IP) rating indicates a light’s resistance to these elements.

- IP65: Dust tight, protected against low-pressure water jets. Good for most tool boxes.

- IP67: Dust tight, protected against temporary immersion in water (up to 1 meter for 30 minutes). Highly recommended for tool boxes frequently exposed to rain, snow, or high humidity.

- IP68: Dust tight, protected against continuous immersion in water. Overkill for most tool boxes but offers maximum protection.

-

Installation Method:

- Adhesive Backing: Common for LED strips and puck lights. Ensure the adhesive is strong and rated for temperature extremes.

- Magnetic Mounts: Offer flexibility for repositioning. Ensure the magnet is robust enough to hold securely through vibrations.

- Screws/Clips: Provide a more permanent and secure installation, often used with rigid LED bars or custom setups.

-

Switching Mechanism:

- Manual On/Off Switch: Simple, reliable, but requires conscious effort.

- Motion Sensor: Automatically turns lights on when the lid is opened or motion is detected. Conserves battery power.

- Pressure Switch (Door-Activated): Mounts near the lid’s hinge or latch, activating lights when the lid opens and turning them off when it closes. Highly convenient.

-

Color Temperature: Measured in Kelvin (K).

- Cool White (5000K-6500K): Brighter, more "daylight" feel, excellent for task lighting and seeing true colors. Most common for tool box lights.

- Warm White (2700K-3500K): Softer, yellowish light, less common for utility lighting.

Installation Guide: Lighting Up Your Tool Box

Installing lights in your truck tool box can be a straightforward DIY project, especially with battery-powered options. For 12V systems, a basic understanding of automotive wiring is beneficial.

-

Plan Your Layout:

- Open your tool box and consider where you want the light. The underside of the lid is a popular choice for full illumination.

- Measure the lengths needed for LED strips.

- Identify potential power source locations if wiring to 12V.

-

Clean the Surface:

- For adhesive-backed lights, thoroughly clean the mounting surface with rubbing alcohol. Ensure it’s dry and free of grease, dust, or dirt. This is crucial for long-lasting adhesion.

-

Mount the Lights:

- LED Strips: Peel off the adhesive backing and firmly press the strip into place. For corners, use flexible connectors or carefully bend the strip (if designed for it). Secure with clips if desired for extra hold.

- Puck/Magnetic Lights: Simply peel and stick, or magnetically attach them to desired locations.

-

Wiring (for 12V Systems):

- Power Source: The easiest way is to tap into an existing 12V accessory circuit that’s only live when the ignition is on, or a constant 12V source if you want lights available even with the truck off. Common points include the dome light circuit (if accessible and appropriate), a trailer wiring harness, or directly from the battery (with a proper fuse).

- Fusing: ALWAYS install an inline fuse (e.g., 2A-5A) near the power source to protect your wiring and truck’s electrical system from shorts.

- Switching:

- Manual Switch: Mount a simple toggle or push-button switch in an accessible location on the tool box or near the truck cab.

- Pressure/Door Switch: These are ideal for automatic operation. Mount the switch so that it is pressed when the lid is closed, breaking the circuit, and releases when the lid opens, completing the circuit and turning on the lights.

- Routing Wires: Carefully route the wires, keeping them away from moving parts, sharp edges, and excessive heat. Use zip ties or wire clips to secure them. Ensure waterproof connectors are used if any part of the wiring is exposed to the elements.

- Connections: Use proper crimp connectors or solder connections for secure and reliable electrical contact. Insulate all connections with heat shrink tubing or electrical tape.

-

Test:

- Before fully securing all wires or closing up panels, test the lights to ensure they function correctly. Check brightness, consistency, and switch operation.

-

Final Touches:

- Secure any loose wires.

- If using battery-powered lights, ensure batteries are fresh.

Maintenance and Tips for Longevity

To ensure your truck tool box lights continue to perform optimally for years, a little maintenance goes a long way.

- Keep Them Clean: Dust, dirt, and grime can accumulate on the light surfaces, reducing their output. Wipe them down periodically with a damp cloth.

- Check Connections: For wired systems, periodically inspect connections for corrosion or looseness, especially after heavy vibrations or exposure to moisture.

- Battery Management: If using battery-powered lights, replace batteries promptly when they dim. For rechargeable units, establish a charging schedule based on usage.

- Protect from Extremes: While IP-rated, prolonged exposure to extreme temperatures (both hot and cold) or direct sunlight can degrade adhesives and electronic components over time.

- Use Proper Adhesives: If original adhesive fails, use a high-quality, outdoor-rated, weather-resistant adhesive or double-sided tape specifically designed for automotive or outdoor use.

Price Table: Lights for Truck Tool Box

| Type of Light | Power Source | Brightness (Lumens) | Key Features | Price Range (USD) |

|---|---|---|---|---|

| LED Strip Light | 12V DC / Battery | 300-1200+ | Customizable length, uniform light, low profile | $20 – $80 |

| LED Puck Light | Battery (AA/AAA/Rechargeable) | 30-100 per unit | Compact, easy install, spot illumination | $15 – $50 (for a multi-pack) |

| Magnetic LED Light | Rechargeable Battery | 150-500 | Portable, repositionable, often rechargeable | $25 – $75 |

| Under-Lid Kit (Specific) | 12V DC | 500-1000 | Integrated design, often vehicle-specific | $50 – $150+ |

| Motion-Activated Light | Battery (integrated) | 100-300 | Hands-free operation, battery saving | $20 – $60 |

Note: Prices are approximate and can vary widely based on brand, features, quality, and where purchased.

Frequently Asked Questions (FAQ)

Q: Are battery-powered lights bright enough for a truck tool box?

A: Yes, many modern battery-powered LED lights are surprisingly bright. For general use, they are often more than sufficient. However, for maximum illumination or continuous use, a 12V wired system might be preferred.

Q: How do I wire lights to my truck’s battery without draining it?

A: Connect them to a switched 12V source (e.g., an accessory circuit that turns off with the ignition) or use a pressure switch that automatically turns the lights off when the tool box lid is closed. Always include an inline fuse for safety. For direct battery connections, consider a low-voltage cut-off switch or a timer.

Q: What IP rating should I look for?

A: An IP65 rating is generally good, offering protection against dust and water splashes. For tool boxes frequently exposed to rain, snow, or high humidity, an IP67 rating provides superior protection against temporary immersion.

Q: Can I use regular LED strips that aren’t specifically for automotive use?

A: You can, but ensure they are rated for 12V (if connecting to your truck’s system) and, crucially, that they have an adequate IP rating (IP65 or IP67) for outdoor or semi-outdoor use. Non-waterproof strips will fail quickly in a tool box environment.

Q: How long do the batteries last in wireless lights?

A: Battery life varies greatly depending on the light’s brightness, usage frequency, battery capacity, and type (alkaline vs. rechargeable lithium-ion). Some can last months with occasional use, while others might need weekly recharging if used extensively.

Q: Will installing lights void my truck’s warranty?

A: Generally, adding accessories like lights won’t void your entire truck’s warranty, but improper installation that damages the vehicle’s electrical system could potentially void the warranty specifically for that damaged system. It’s best to use proper wiring techniques, fuses, and, if unsure, consult a professional.

Conclusion

Illuminating your truck tool box is a small investment that yields significant returns in convenience, efficiency, and safety. No longer will you dread reaching into a dark abyss, searching blindly for tools. With the right lighting solution – be it flexible LED strips, convenient puck lights, or robust magnetic units – your mobile workshop will be transformed into a productive and inviting space, ready for any task, day or night. By considering the types of lights available, key features like power source and durability, and following proper installation techniques, you can easily light up your truck tool box and bring a new level of functionality to your work or hobbies on the go.

Trucks for Sale Find the best deals on used trucks for sale across the USA. Browse pickups, semi trucks, dump trucks and more – updated daily

Trucks for Sale Find the best deals on used trucks for sale across the USA. Browse pickups, semi trucks, dump trucks and more – updated daily