How to Wire Trailer Lights to Truck: A Comprehensive Guide for Safe Towing

How to Wire Trailer Lights to Truck: A Comprehensive Guide for Safe Towing

Towing a trailer, whether for work or recreation, opens up a world of possibilities. From hauling equipment to embarking on a camping adventure, a trailer can significantly extend your vehicle’s capabilities. However, before you hit the road, one crucial aspect demands your attention: ensuring your trailer lights are properly wired to your truck. This isn’t just a matter of convenience; it’s a fundamental requirement for safety and legal compliance.

Learning how to wire trailer lights to truck is a skill that empowers you to tow confidently, knowing that your turn signals, brake lights, and running lights are clearly communicating your intentions to other drivers. A correctly wired system prevents accidents, avoids costly fines, and ensures a smooth, worry-free journey. This comprehensive guide will walk you through every step of how to wire trailer lights to truck, from understanding the basics to troubleshooting common issues, ensuring your setup is safe, reliable, and road-ready.

Understanding the Basics of Trailer Wiring

Before diving into the practical steps of how to wire trailer lights to truck, it’s essential to grasp the fundamental principles. Trailer lights serve the same purpose as your vehicle’s lights: to signal turns, indicate braking, and make your presence known, especially at night. Without proper illumination, your trailer becomes a significant hazard.

The core of trailer wiring revolves around a standardized connector system that transmits electrical signals from your truck to the trailer’s lights. The most common types you’ll encounter are:

- 4-Pin Connector: This is the simplest and most common connector, typically found on small utility trailers or boat trailers that don’t have electric brakes or auxiliary power needs. It provides connections for:

- Brown: Taillights, running lights, and side marker lights.

- Yellow: Left turn signal and brake light.

- Green: Right turn signal and brake light.

- White: Ground.

- 5-Pin Connector: Adds a wire for a reverse light or a hydraulic brake lockout function for boat trailers.

- 6-Pin Connector: Less common, but can offer additional functions like auxiliary power or reverse lights.

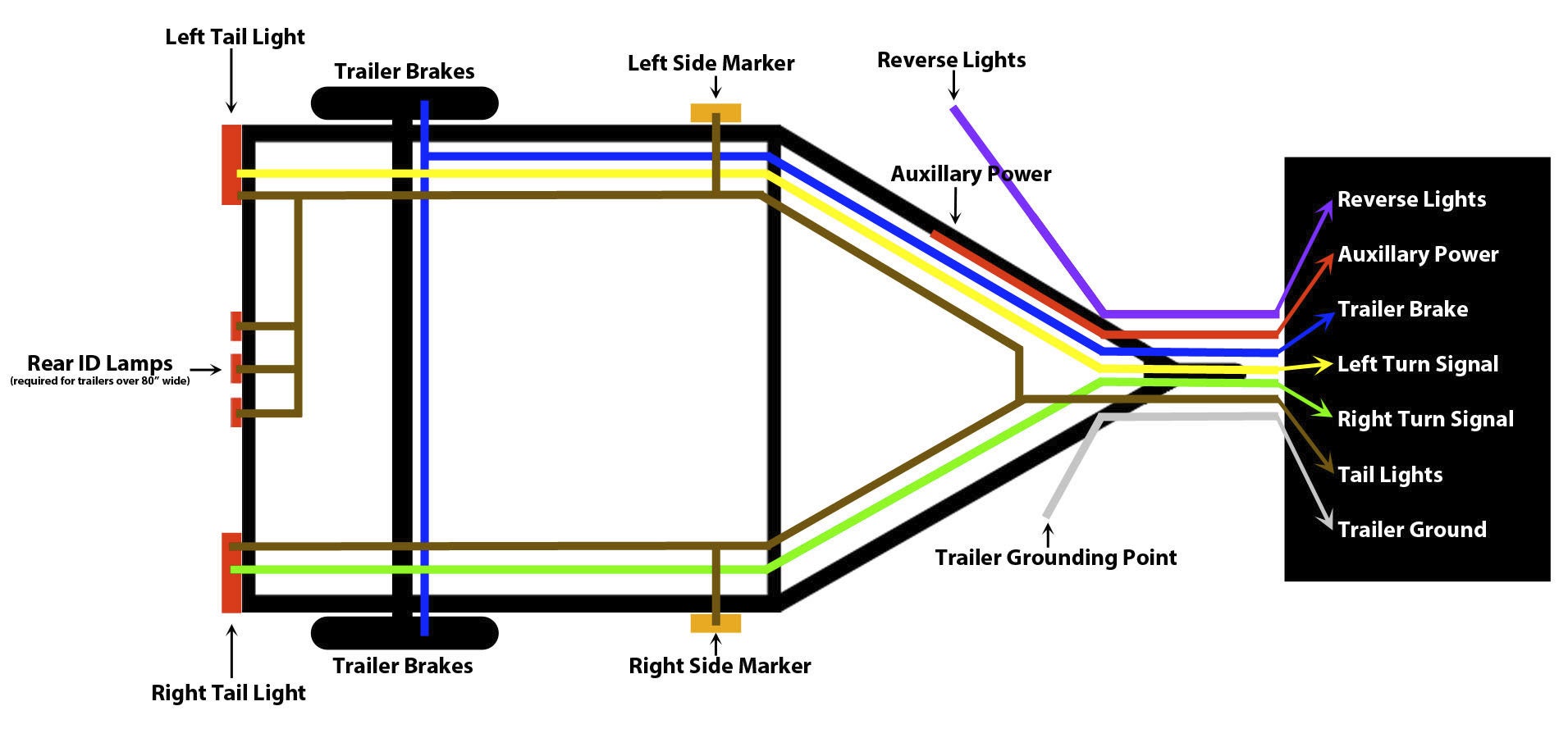

- 7-Pin RV Blade Connector: The most comprehensive connector, prevalent on larger travel trailers, enclosed trailers, and fifth-wheel campers. It includes all the functions of a 4-pin, plus:

- Blue: Electric trailer brakes.

- Black: 12-volt auxiliary power (for charging batteries or powering interior lights).

- Purple/Red (or sometimes Yellow): Reverse lights.

For the purpose of how to wire trailer lights to truck, we will primarily focus on the 4-pin and 7-pin systems, as they cover the vast majority of towing scenarios.

Pre-Installation Checklist and Safety First

Before you begin the process of how to wire trailer lights to truck, thorough preparation is key. Safety should always be your top priority.

- Vehicle and Trailer Compatibility: Ensure your truck is equipped for towing. Many modern trucks come with a factory towing package, which simplifies the wiring process significantly. If not, you may need to install a T-connector wiring harness or a universal kit.

- Check Existing Wiring: Inspect your truck’s rear for any existing trailer wiring connectors. Sometimes they’re tucked away behind the bumper or in the spare tire well.

- Gather Your Tools and Materials:

- Wire Strippers/Cutters: For precise wire preparation.

- Crimping Tool: For secure, solderless connections.

- Heat Gun (optional but recommended): For heat-shrink tubing.

- Multimeter or Circuit Tester: Essential for identifying vehicle wires and troubleshooting.

- Wire Connectors: Butt connectors, quick splices, or solder and heat shrink tubing.

- Electrical Tape: For added insulation and protection.

- Zip Ties or Wire Loom: For neat and secure cable management.

- Dielectric Grease: To protect connections from moisture and corrosion.

- Safety Glasses and Gloves: Always protect your eyes and hands.

- Jack Stands (if working under the vehicle): Never rely solely on a jack.

- Disconnect the Battery: Always disconnect your truck’s negative battery terminal before working on any electrical system. This prevents accidental shorts and electrical shocks.

Step-by-Step Guide: How to Wire Trailer Lights to Truck (4-Pin Connector)

Wiring a 4-pin connector is the most straightforward method for how to wire trailer lights to truck.

-

Locate Your Truck’s Tail Light Wires:

- Open your truck’s tailgate and locate the tail light assemblies. You’ll typically find a bundle of wires leading to them.

- The easiest way to identify the correct wires is by using a circuit tester or multimeter.

- Turn on your truck’s headlights/parking lights and test each wire until you find the one that shows voltage. This is your tail/running light wire (brown).

- Turn on your left turn signal and test wires until you find the one that flashes with the signal. This is your left turn/brake wire (yellow).

- Repeat for the right turn signal to find your right turn/brake wire (green).

- The ground wire (white) can usually be attached to a clean, unpainted metal surface on the truck’s frame, or to an existing ground wire if one is readily available.

- Pro Tip: Many vehicles have specific wiring harnesses or "T-connectors" available that plug directly into your tail light assembly, simplifying this step immensely. If available for your vehicle, this is highly recommended.

-

Make the Connections:

- Once you’ve identified the corresponding wires on your truck, you’ll connect them to the wires on your trailer wiring harness.

- Brown to Brown: Truck’s tail/running light wire to the trailer harness brown wire.

- Yellow to Yellow: Truck’s left turn/brake wire to the trailer harness yellow wire.

- Green to Green: Truck’s right turn/brake wire to the trailer harness green wire.

- White to a Clean Ground: Securely attach the trailer harness white wire to a clean, unpainted metal part of your truck’s frame, or a factory ground point. Sand away any paint or rust for a good connection.

-

Secure the Connections:

- Crimping: Use high-quality crimp connectors (butt connectors are common) and a proper crimping tool. Ensure a tight, secure crimp.

- Soldering (Recommended): For the most durable connection, solder the wires together. Once soldered, insulate the connection with heat-shrink tubing. This provides excellent protection against moisture and corrosion.

- Electrical Tape: After crimping or soldering, wrap the connections tightly with electrical tape for an extra layer of protection.

-

Mount the Connector:

- Choose a location near your truck’s hitch that is easily accessible but protected from road debris and potential damage.

- Use screws or a mounting bracket to secure the 4-pin connector.

-

Test the Lights:

- Reconnect your truck’s battery.

- Plug the trailer’s 4-pin connector into your newly installed truck connector.

- Turn on your truck’s headlights/parking lights – the trailer’s running lights should illuminate.

- Activate the left turn signal – the trailer’s left turn light should flash.

- Activate the right turn signal – the trailer’s right turn light should flash.

- Press the brake pedal – both trailer turn/brake lights should illuminate steadily.

- If any lights aren’t working, proceed to the troubleshooting section.

Step-by-Step Guide: Upgrading to a 7-Pin Connector

For trailers with electric brakes, auxiliary power needs, or reverse lights, you’ll need a 7-pin connector. This process for how to wire trailer lights to truck is more involved and often requires a dedicated trailer wiring kit or a factory towing package.

- Existing 4-Pin Base: Often, a 7-pin connector installation starts with an existing 4-pin setup or a direct connection to your truck’s tail light wiring.

- Brake Controller Installation: For electric trailer brakes, a brake controller is essential. This device, usually mounted in your truck’s cab, modulates the power sent to the trailer’s brakes. Installation typically involves:

- Power (Black Wire): Connects to a dedicated fused 12V power source from your truck’s battery.

- Ground (White Wire): Connects to a good chassis ground.

- Brake Signal (Red Wire): Connects to your truck’s cold side of the brake light switch (the wire that only gets power when the brake pedal is pressed).

- Brake Output (Blue Wire): This wire runs from the brake controller back to the 7-pin connector at the rear of the truck.

- Auxiliary Power (Black Wire): This wire provides a constant 12V power supply to the trailer for charging batteries or powering accessories. It typically runs directly from your truck’s battery, through a circuit breaker or fuse, to the 7-pin connector.

- Reverse Lights (Purple/Red/Yellow Wire): This wire connects to your truck’s reverse light circuit, activating the trailer’s reverse lights when you shift into reverse.

- Connecting to the 7-Pin Socket: All these additional wires, along with the standard 4-pin functions (brown, yellow, green, white), will terminate at the 7-pin RV blade socket mounted near your hitch. Ensure each wire is connected to its corresponding pin on the socket.

- Secure and Protect: As with the 4-pin, use robust connections (solder and heat shrink recommended), secure all wiring with zip ties or wire loom, and apply dielectric grease to the connector pins to prevent corrosion.

- Test All Functions: After installation, meticulously test every function: running lights, left turn, right turn, brake lights, reverse lights, and (if applicable) the trailer brakes with the brake controller.

Troubleshooting Common Trailer Light Issues

Even with careful installation, issues can arise. Knowing how to wire trailer lights to truck also means knowing how to troubleshoot them.

- No Lights at All:

- Check Truck Fuses: Many trucks have dedicated fuses for trailer lighting circuits. Check your vehicle’s fuse box (under the hood or dash) for blown fuses.

- Bad Ground Connection: This is the most common culprit. Ensure the white ground wire has a clean, solid connection to the truck’s frame. Rust or paint can interfere.

- Corroded Connections: Inspect all connections for rust or corrosion, especially inside the plug. Clean with a wire brush or electrical contact cleaner.

- Broken Wire: Visually inspect the wiring for any cuts, pinches, or breaks.

- Flickering Lights or Intermittent Operation:

- Often points to a loose or intermittent ground connection.

- Could also be a loose wire within the connector or a partially broken wire.

- One Side Not Working (e.g., Left Turn Signal Only):

- Check the specific wire for that function (e.g., yellow for left turn) at both the truck and trailer ends.

- Inspect the bulb on the trailer.

- Brake Lights Not Working (but turn signals do):

- For 4-pin, this is unlikely as turn/brake share the same wire. Check the truck’s brake light switch or fuse.

- For 7-pin with a brake controller, check the brake controller’s settings, its power supply, and the blue output wire.

- Using a Multimeter: A multimeter is an invaluable tool for troubleshooting. You can test for voltage at various points in the circuit to pinpoint where the power flow is interrupted.

Important Considerations and Tips

- Weatherproofing: Always use heat-shrink tubing, dielectric grease, and high-quality electrical tape on all connections to protect them from moisture, road salt, and corrosion.

- Cable Management: Secure all wiring neatly using zip ties or wire loom. Keep wires away from hot exhaust components, moving parts, and sharp edges. This prevents damage and ensures longevity.

- Regular Maintenance: Periodically inspect your trailer wiring and connections. Clean the connector pins, check for fraying wires, and apply dielectric grease annually.

- Professional Installation vs. DIY: While how to wire trailer lights to truck is a manageable DIY project for a 4-pin setup, a 7-pin system with a brake controller can be more complex. If you’re uncomfortable with electrical work or dealing with vehicle-specific wiring, don’t hesitate to consult a professional.

- Local Regulations: Always be aware of local and state regulations regarding trailer lighting. These can vary, but generally, running lights, brake lights, and turn signals are mandatory.

Estimated Cost Table for Trailer Wiring Components

Understanding how to wire trailer lights to truck also involves knowing the potential costs of components. Prices are approximate and can vary widely based on brand, quality, and retailer.

| Component | Estimated Price Range (USD) | Notes |

|---|---|---|

| 4-Pin Wiring Kit (Basic) | $20 – $50 | Includes connector, some wire, splices. |

| 7-Pin Wiring Kit (Complete) | $70 – $200+ | May include converter, relays, circuit breakers, and more robust wiring. Often vehicle-specific. |

| Trailer Brake Controller | $80 – $300 | Essential for electric brakes. Proportional controllers are recommended for smoother braking. |

| Wire Strippers/Cutters | $10 – $30 | Basic tool. |

| Crimping Tool | $15 – $40 | For non-soldered connections. |

| Multimeter/Circuit Tester | $15 – $50 | Essential for testing and troubleshooting. |

| Butt Connectors (Pack) | $5 – $15 | Assorted sizes, heat-shrinkable ones are best. |

| Heat Shrink Tubing (Assorted) | $10 – $25 | Provides excellent insulation and weatherproofing. |

| Electrical Tape | $3 – $10 | High-quality, weather-resistant tape. |

| Dielectric Grease | $5 – $15 | Small tube, prevents corrosion. |

| Zip Ties / Wire Loom (Roll) | $5 – $20 | For neat and protected wire routing. |

| Total Estimated DIY Cost (4-Pin) | $50 – $150 | If you have some basic tools already. |

| Total Estimated DIY Cost (7-Pin) | $150 – $500+ | Varies significantly based on truck’s existing setup and brake controller choice. Excludes professional labor. |

Frequently Asked Questions (FAQ)

Q1: Do I need a brake controller if my trailer has electric brakes?

A1: Yes, absolutely. A brake controller is legally required and essential for safely operating a trailer with electric brakes. It allows you to adjust and activate the trailer’s brakes, preventing dangerous sway and improving stopping performance.

Q2: What’s the main difference between a 4-pin and a 7-pin connector?

A2: A 4-pin connector provides basic lighting functions (running lights, turn signals, brake lights, and ground). A 7-pin connector includes these, plus dedicated circuits for electric trailer brakes, 12-volt auxiliary power (for charging or powering accessories), and sometimes reverse lights.

Q3: My trailer lights are flickering. What could be wrong?

A3: Flickering lights are most commonly caused by a poor or intermittent ground connection. Check the white ground wire connection on both your truck and trailer. It could also be a loose wire connection within the plug or a partially damaged wire.

Q4: Can I just splice into my truck’s existing tail light wires?

A4: For simple 4-pin setups, direct splicing is possible, especially with a universal wiring kit. However, for modern vehicles with complex electrical systems (CAN bus), it’s highly recommended to use a vehicle-specific T-connector harness or a powered converter to avoid overloading circuits or triggering error codes.

Q5: How do I find the correct wire colors on my truck?

A5: The best method is to use a circuit tester or multimeter to identify the wires by their function (power when lights are on, flashes with turn signals, etc.). While standard color codes exist for trailer harnesses, truck manufacturers’ wire colors can vary. Always test to be sure.

Q6: My new trailer has LED lights, does that change anything for wiring?

A6: For most basic wiring, no. LED lights draw less power, which is often a benefit. However, some older trucks or vehicles with complex bulb-out detection systems might require a load resistor for LED turn signals to prevent hyper-flashing or "bulb out" warnings.

Conclusion

Mastering how to wire trailer lights to truck is an invaluable skill for any towing enthusiast or professional. It’s a critical step in ensuring the safety of your cargo, your vehicle, and everyone else on the road. By understanding the different wiring configurations, meticulously following the installation steps, and knowing how to troubleshoot common issues, you can confidently prepare your truck and trailer for any journey.

Remember, proper wiring isn’t just a recommendation; it’s a legal and safety imperative. Take your time, use quality components, and perform thorough testing. With this comprehensive guide, you’re well-equipped to tackle the task of how to wire trailer lights to truck, ensuring a bright, safe, and successful towing experience every time.