Cable Placing Trucks for Sale: Your Comprehensive Guide to Acquiring Essential Infrastructure Equipment

Cable Placing Trucks for Sale: Your Comprehensive Guide to Acquiring Essential Infrastructure Equipment

In the intricate world of modern infrastructure development, from the sprawling networks of telecommunications to the robust grids of power distribution, one piece of equipment stands as an unsung hero: the cable placing truck. These specialized vehicles are the backbone of efficient and safe cable installation, designed to handle the demanding tasks of laying, pulling, and tensioning various types of cables across diverse terrains and environments. Whether you’re a burgeoning contractor, an established utility company, or an independent professional looking to expand your capabilities, understanding the nuances of "cable placing trucks for sale" is paramount. This comprehensive guide will delve into what these essential machines are, why they are a critical investment, the different types available, key considerations for purchase, and practical advice to ensure you make an informed decision that drives your project success.

What Exactly Are Cable Placing Trucks?

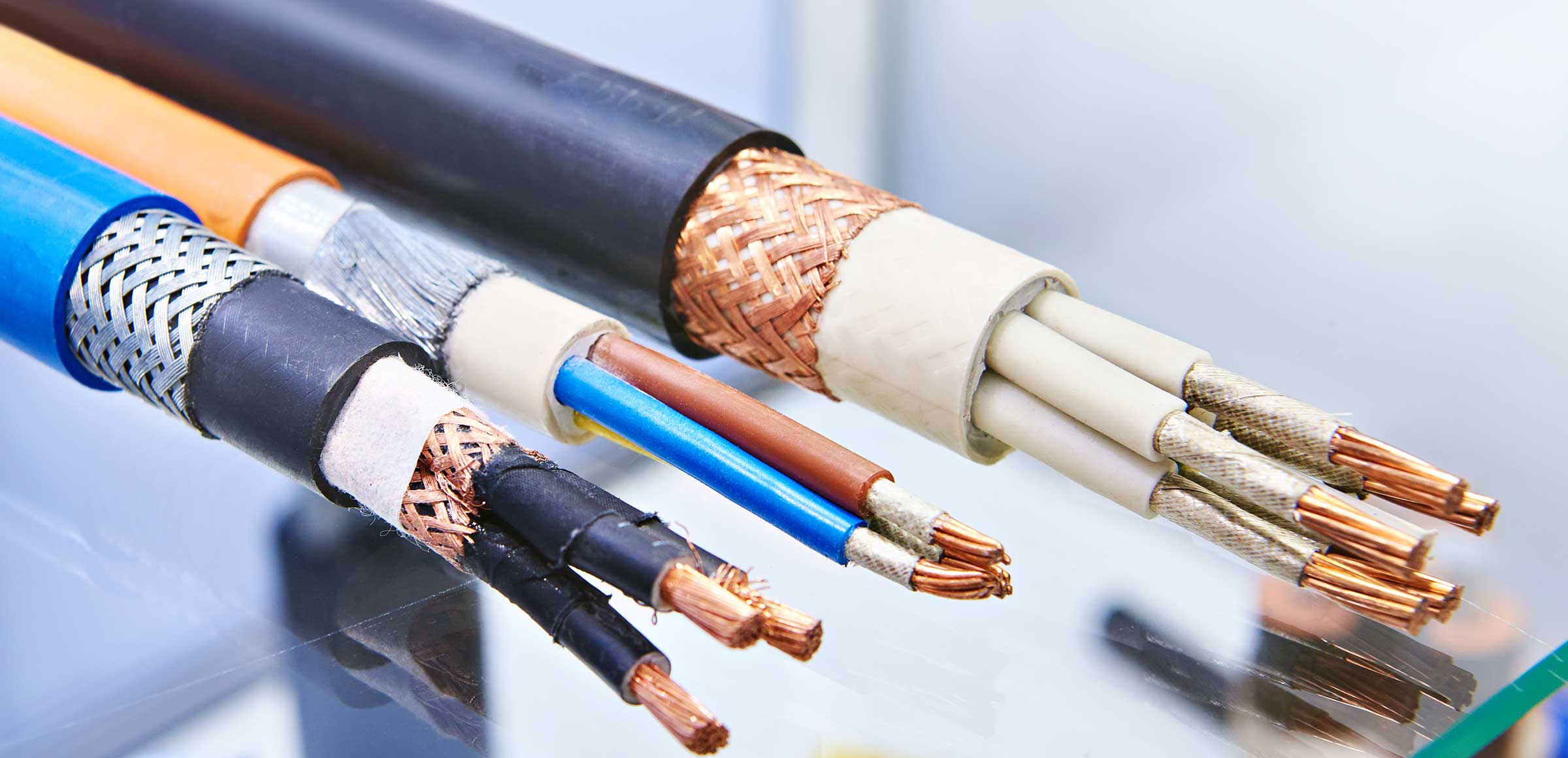

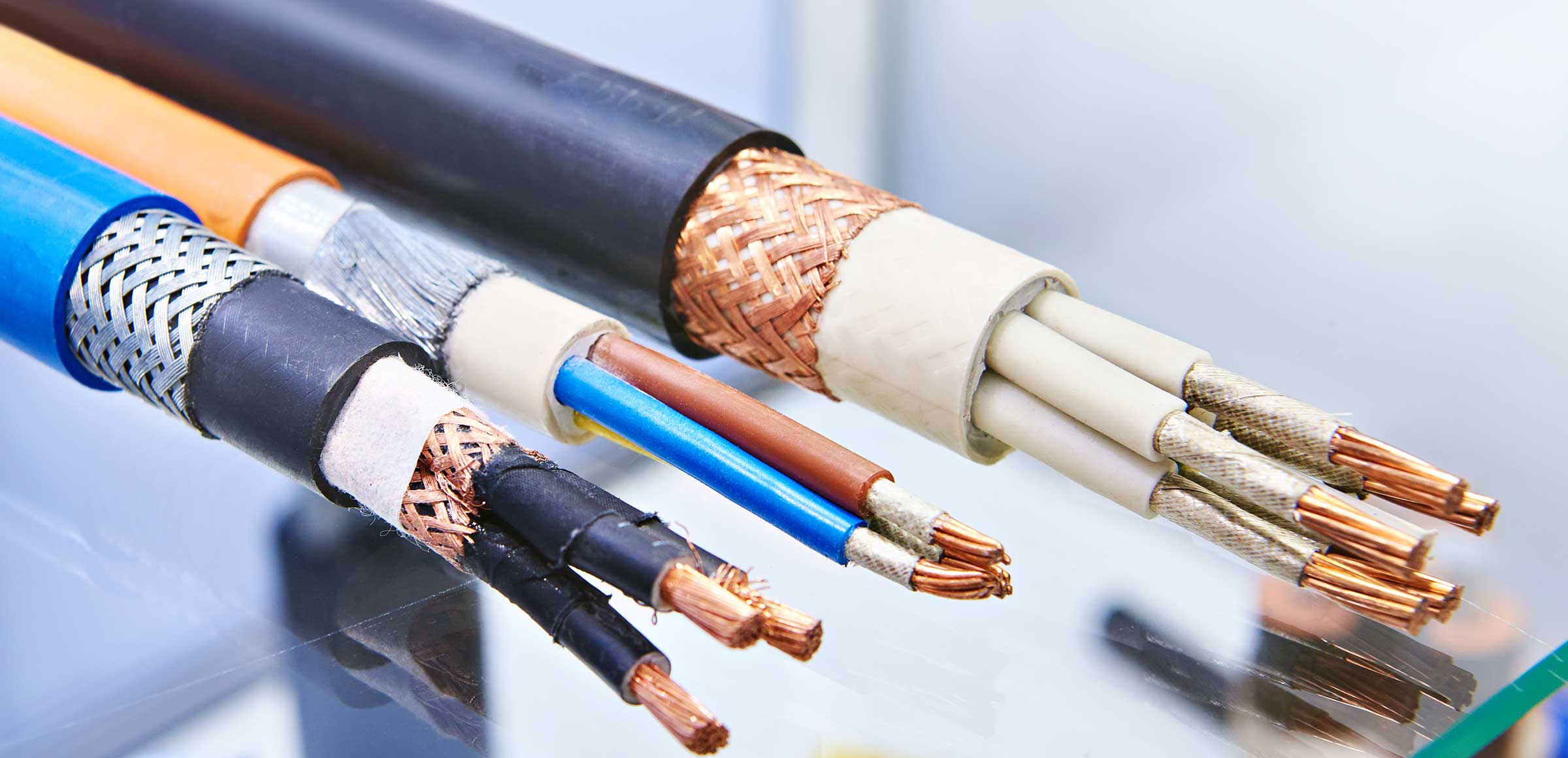

At their core, cable placing trucks are heavy-duty vehicles specifically engineered to facilitate the deployment of cables. While often broadly referred to, they encompass a range of machinery, including cable pullers, tensioners, reel trucks, and line trucks, each with specialized functions. Their primary role is to efficiently and safely unspool, guide, and pull cables – be it fiber optic, copper, or high-voltage power lines – into conduits, across open trenches, or overhead between poles.

A typical cable placing truck is an integrated system comprising several critical components:

- Reel Carriers/Loaders: Mechanisms to safely transport and precisely unspool large, heavy cable reels.

- Pulling Winches: Hydraulic or mechanical winches that provide the necessary pulling force to draw cables through conduits or across distances.

- Tensioning Systems: Devices that maintain optimal tension on the cable during installation, preventing damage and ensuring proper sag.

- Booms/Cranes: Often integrated for lifting reels, placing poles, or assisting with overhead work.

- Hydraulic Systems: The power source for most functions, ensuring smooth and controlled operation.

- Control Panels: Intuitive interfaces for operators to manage pulling speed, tension, and other parameters.

- Safety Features: Overload protection, emergency stops, and robust braking systems are standard.

These trucks are designed to handle the immense weight and delicate nature of various cables, minimizing labor, increasing speed, and significantly enhancing safety on job sites.

Why Invest in a Cable Placing Truck? Benefits & Applications

Acquiring a dedicated cable placing truck is more than just purchasing equipment; it’s an investment in operational efficiency, safety, and project scalability.

Key Benefits Include:

- Increased Efficiency: Automating the strenuous task of cable pulling dramatically reduces installation time compared to manual methods. This translates to faster project completion and higher throughput.

- Reduced Labor Costs: Fewer personnel are required for heavy lifting and pulling, freeing up your workforce for other critical tasks and reducing overall labor expenses.

- Enhanced Safety: By mechanizing the process, the risk of worker injuries associated with heavy lifting, repetitive strain, and uncontrolled cable movement is significantly minimized. Modern trucks incorporate numerous safety interlocks and controls.

- Precision and Control: Advanced hydraulic and electronic control systems allow for precise regulation of pulling force and speed, preventing cable damage, over-tensioning, or snagging.

- Versatility: Many trucks can be configured for various cable types and sizes, making them a versatile asset for a range of projects.

- Professional Image: Utilizing specialized, well-maintained equipment projects a professional image, instilling confidence in clients and potentially leading to more lucrative contracts.

Applications Across Industries:

Cable placing trucks are indispensable across multiple sectors:

- Telecommunications: Essential for deploying fiber optic cables (FTTH, FTTC, backbone networks), coaxial cables, and traditional copper lines for internet, TV, and phone services.

- Power Utilities: Crucial for installing and maintaining underground and overhead power transmission and distribution lines, including high-voltage cables.

- Civil Engineering: Used in urban development for street lighting cables, traffic signal lines, and various utility conduits.

- Renewable Energy: Instrumental in cabling large-scale solar farms and wind turbine arrays, connecting them to the grid.

Types and Categories of Cable Placing Trucks

The market for cable placing trucks offers a diverse range of machines, each tailored for specific applications, capacities, and operational environments. Understanding these categories is vital for selecting the right equipment.

-

Self-Propelled Reel Trucks/Reel Trailers:

- Self-Propelled: These are integrated units where the reel carrier and pulling/tensioning equipment are mounted directly onto a truck chassis. They offer excellent mobility and are ideal for jobs requiring frequent relocation.

- Reel Trailers: Smaller, more portable units that are towed by a separate vehicle. They are cost-effective for lighter jobs or where space is limited. They primarily serve as reel carriers, often requiring a separate pulling mechanism.

-

Underground Cable Pullers:

- Specifically designed for pulling cables through underground conduits, often requiring significant pulling force. They typically feature powerful winches, robust hydraulic systems, and sometimes capstan-style pulling mechanisms to prevent cable damage. They can range from compact units for residential services to massive machines for trunk lines.

-

Overhead Line Trucks / Bucket Trucks with Pulling Capabilities:

- While primarily known for aerial work with their articulating or telescopic booms (bucket trucks), many are equipped with auxiliary winches and tensioners suitable for light to medium overhead cable pulling and stringing. These offer versatility for companies performing both aerial installation and maintenance.

-

Dedicated Tensioners & Pullers:

- For large-scale, long-distance, or high-tension power line installations, specialized pullers and tensioners are used. These are often standalone units, sometimes trailer-mounted, designed for extremely high pulling capacities (e.g., thousands of pounds) and precise tension control, critical for maintaining conductor integrity over long spans.

-

Multi-Purpose Cable Placer/Plough Trucks:

- Some advanced units combine cable laying with trenching or vibratory ploughing capabilities, allowing for direct burial of cables without prior trench excavation. These are highly efficient for specific terrains but represent a significant investment.

The choice among these types depends heavily on the specific nature of your projects, the types and sizes of cables you handle, the terrain, and your budget.

Key Considerations When Buying a Cable Placing Truck

Purchasing a cable placing truck is a significant investment that requires careful evaluation. Here are the critical factors to consider:

-

New vs. Used:

- New: Offers the latest technology, full warranty, and no prior wear and tear. Higher upfront cost.

- Used: More budget-friendly, but requires thorough inspection. Potential for hidden issues, shorter lifespan, and less advanced features. Look for well-maintained units with service records.

-

Budget & Operating Costs:

- Beyond the purchase price, factor in fuel consumption, maintenance, insurance, training for operators, and potential licensing or permit costs. Calculate the total cost of ownership (TCO) over the expected lifespan.

-

Project Requirements:

- Cable Type & Size: Are you handling delicate fiber, heavy power cables, or both? This determines the required reel capacity, pulling force, and tensioning precision.

- Underground vs. Overhead: Specialized features are needed for each.

- Terrain: Off-road capabilities (4WD, high ground clearance) are essential for rough or remote sites.

- Distance & Length of Pull: Longer pulls require more powerful winches and larger reel capacities.

- Conduit Size/Condition: Affects required pulling force and potential for snags.

-

Truck Chassis Specifications:

- Engine Power & Torque: Sufficient power is crucial, especially for heavy loads and challenging terrain.

- Transmission: Automatic vs. manual; consider ease of operation and specific job needs.

- Drivetrain: 2WD for paved roads, 4WD or even 6×6 for off-road or muddy conditions.

- GVWR (Gross Vehicle Weight Rating): Ensure it can safely carry the truck’s weight plus the heaviest cable reels.

-

Cable Placing Equipment Specifications:

- Pulling Force (lbs/kN): Match this to the maximum expected cable weight and resistance. Always err on the side of caution with capacity.

- Reel Capacity: Max diameter, width, and weight of the cable reels the truck can safely transport and deploy.

- Boom/Crane Reach & Lift Capacity: If applicable, ensure it meets your overhead work needs.

- Hydraulic System: Robustness, flow rate, and pressure for smooth and powerful operation.

- Control System: Ease of use, precision, and availability of remote controls for operator safety and efficiency.

-

Safety Features:

- Look for essential safety features like emergency stop buttons, automatic overload protection, anti-tipping systems, adequate lighting, and clear operator visibility. Remote controls enhance safety by keeping operators away from moving parts.

-

Maintenance, Parts & Support:

- Investigate the availability of spare parts and the ease of maintenance. Some manufacturers have better support networks than others. Inquire about warranty coverage, training programs, and after-sales service.

-

Manufacturer Reputation & Resale Value:

- Reputable brands often offer better reliability, superior technology, and higher resale value. Research brands known for quality and durability in the industry (e.g., Altec, Versalift, Terex, Condux, Sherman + Reilly, Pengo).

-

Regulatory Compliance:

- Ensure the truck complies with all local, state, and national regulations, including DOT (Department of Transportation), OSHA (Occupational Safety and Health Administration), and emissions standards.

Where to Find Cable Placing Trucks for Sale (Practical Advice)

Finding the right cable placing truck involves exploring various channels:

- Authorized Dealerships: Ideal for new trucks, offering warranties, financing options, and expert advice. Many also sell certified used equipment.

- Heavy Equipment Online Marketplaces: Websites like MachineryTrader.com, IronPlanet.com, EquipmentTrader.com, and TruckPaper.com specialize in used heavy machinery, often with detailed listings and inspection reports.

- Auctions: Both live and online auctions (e.g., Ritchie Bros. Auctioneers, GovPlanet) can be sources for good deals, but require careful inspection as sales are often "as-is."

- Direct from Owners/Contractors: Companies upgrading their fleets may sell their older, well-maintained trucks directly. Networking within the industry can uncover these opportunities.

- Rental Companies: Large equipment rental firms frequently sell off their aging inventory to make room for new models. These trucks are often well-maintained but may have high hours.

Tips for a Successful Purchase:

- Thorough Inspection: Always conduct a physical inspection of the truck, preferably by a qualified mechanic specializing in heavy equipment. Check the engine, transmission, hydraulics, frame, and all cable-placing components.

- Test All Functions: Operate the winch, tensioner, boom, and all controls to ensure they function smoothly and correctly.

- Review Maintenance Records: Ask for detailed service history to understand past repairs and maintenance.

- Understand Hidden Costs: Account for sales tax, delivery fees, registration, insurance, and any necessary repairs or upgrades.

- Get a Clear Bill of Sale: Ensure all details of the purchase, condition, and warranty (if any) are clearly documented.

Estimated Price Guide for Cable Placing Trucks

Prices for cable placing trucks vary significantly based on type, condition (new/used), capacity, features, and manufacturer. The table below provides a general estimate for illustrative purposes and is subject to market fluctuations, location, and specific configurations.

| Type of Truck | Condition | Pulling Capacity (lbs) | Reel Capacity (Dia. x Width) | Key Features | Estimated Price Range (USD) |

|---|---|---|---|---|---|

| Trailer-Mounted Cable Puller | Used | 500 – 2,000 | 60" x 36" | Compact, portable, basic controls, gas/diesel engine | $10,000 – $30,000 |

| Trailer-Mounted Cable Puller | New | 1,000 – 3,000 | 72" x 48" | Advanced hydraulics, remote control, safety features | $35,000 – $70,000 |

| Self-Propelled Reel Truck | Used | 3,000 – 8,000 | 96" x 60" | Medium-duty chassis, hydraulic reel loader, winch | $40,000 – $120,000 |

| Self-Propelled Reel Truck | New | 5,000 – 15,000 | 108" x 72" | Heavy-duty chassis, powerful winch, boom options | $150,000 – $350,000+ |

| Underground Cable Puller | Used | 6,000 – 12,000 | N/A (for conduit pulling) | High-force winch, capstan/bullwheel, robust frame | $50,000 – $150,000 |

| Underground Cable Puller | New | 10,000 – 25,000+ | N/A (for conduit pulling) | Precision controls, data logging, advanced safety | $180,000 – $400,000+ |

| Overhead Line Truck (w/ Pull) | Used | 1,000 – 5,000 | N/A (Boom/Bucket focus) | Bucket lift, auxiliary winch, light-medium pulling | $60,000 – $180,000 |

| Dedicated Tensioner Unit | New | 10,000 – 40,000+ | N/A (for high-tension lines) | Precise tension control, multiple bullwheels, remote | $200,000 – $700,000+ |

Note: These are estimated ranges. Actual prices will vary based on specific features, customization, market demand, and economic conditions.

Frequently Asked Questions (FAQ) About Cable Placing Trucks

Q1: What’s the typical lifespan of a cable placing truck?

A1: With proper maintenance, a cable placing truck can have a lifespan of 15 to 25 years or more. Key factors include the quality of the original build, adherence to maintenance schedules, and the severity of operating conditions.

Q2: Can I use a cable placing truck for both underground and overhead work?

A2: While some multi-purpose trucks (like certain line trucks with auxiliary winches) can handle both, dedicated underground pullers and overhead tensioners are optimized for their specific tasks. For diverse work, you might need specialized attachments or even two different types of equipment.

Q3: What kind of maintenance is required for these trucks?

A3: Regular maintenance includes routine engine service (oil changes, filters), hydraulic system checks (fluid levels, hose integrity), winch and tensioner mechanism inspection (cables, gears, brakes), chassis lubrication, and tire maintenance. Following the manufacturer’s recommended service schedule is crucial.

Q4: Is financing available for cable placing trucks?

A4: Yes, most dealerships and heavy equipment lenders offer various financing options, including loans, leases, and lease-to-own programs. Interest rates and terms will depend on your creditworthiness and the age/value of the truck.

Q5: How do I determine the right pulling capacity for my needs?

A5: Assess the heaviest cable you’ll regularly pull, the longest anticipated run, and the potential for friction (e.g., tight conduits, multiple bends). It’s always advisable to choose a truck with a pulling capacity that exceeds your maximum calculated need by at least 20-30% to ensure safety and account for unforeseen resistance.

Q6: Are there specific training requirements for operating these trucks?

A6: Yes, operating cable placing trucks requires specialized training to ensure safety and efficiency. Operators should be trained on proper setup, operation of all controls, safety protocols (e.g., lockout/tagout, pinch points), and troubleshooting. OSHA and local regulations may mandate specific certifications.

Q7: What are some common reputable brands to look for when buying a cable placing truck?

A7: Some of the most well-known and reputable brands in the industry include Altec, Versalift, Terex, Condux, Sherman + Reilly, Pengo, Hogg & Davis, and Spiradrill. Researching these brands can provide a good starting point for your search.

Conclusion

Cable placing trucks are more than just vehicles; they are indispensable tools that underpin the expansion and maintenance of our vital infrastructure. Investing in the right cable placing truck for sale can significantly enhance your operational efficiency, reduce labor costs, and most importantly, ensure the safety of your workforce. By carefully considering your project requirements, understanding the various types of trucks available, and meticulously evaluating each potential purchase based on key specifications, maintenance history, and vendor support, you can make an informed decision. A well-chosen cable placing truck is not just an expense, but a strategic investment that will yield substantial returns in terms of productivity, reliability, and the successful completion of critical infrastructure projects for years to come.