Extended CV Axles for Lifted Trucks: A Comprehensive Guide

Extended CV Axles for Lifted Trucks: A Comprehensive Guide

For enthusiasts and professionals alike, lifting a truck is more than just a cosmetic upgrade; it’s about enhancing capability, ground clearance, and often, achieving a more aggressive stance. However, modifying a vehicle’s suspension geometry introduces a cascade of engineering challenges that must be addressed to maintain reliability and performance. Among the most critical components affected by a lift are the Constant Velocity (CV) axles, particularly in trucks equipped with Independent Front Suspension (IFS). This comprehensive guide delves into the world of extended CV axles for lifted trucks, explaining their purpose, benefits, types, and how to make the right choice for your rig.

Understanding the Problem: Lifted Trucks and OEM CV Axles

CV axles are a vital part of your truck’s drivetrain, transmitting power from the differential to the wheels while allowing for suspension travel and steering articulation. In trucks with IFS, these axles are designed to operate efficiently within a specific range of angles determined by the factory suspension setup.

When a truck is lifted, especially using spacer or coilover lifts that push the control arms downwards without correcting the differential position, the CV axles are forced to operate at significantly steeper angles. This increased angle places immense stress on the CV joints and boots. The rubber boots, designed to protect the internal components from dirt and moisture while retaining grease, are stretched and compressed beyond their intended limits, leading to premature cracking and tearing. Once a boot fails, grease escapes, and contaminants enter, rapidly accelerating wear on the CV joint’s internal cage, race, and bearings.

The consequences of operating OEM CV axles at these extreme angles are severe:

- Premature Wear and Failure: The constant, excessive friction and pressure lead to rapid wear of the internal components, resulting in clicking, popping, or grinding noises, especially during turns or when engaging four-wheel drive.

- Boot Failure: Torn boots expose the joints to the elements, leading to early component failure and costly repairs.

- Vibrations: Incorrect axle angles can induce vibrations, particularly at certain speeds, impacting ride quality and potentially damaging other drivetrain components.

- Reduced Drivetrain Efficiency: Stressed joints waste power and create heat, reducing the overall efficiency of your truck’s power transfer.

- Off-Road Vulnerability: The already compromised OEM axles become highly susceptible to catastrophic failure under the increased stress of off-road driving, leaving you stranded.

What Are Extended CV Axles?

Extended CV axles are aftermarket components specifically designed to mitigate the issues associated with lifting IFS trucks. They are engineered to be slightly longer than their OEM counterparts, effectively reducing the operating angle of the CV joints when the suspension is extended by a lift. This increased length helps restore the CV joint angles closer to their factory-intended range, even with several inches of lift.

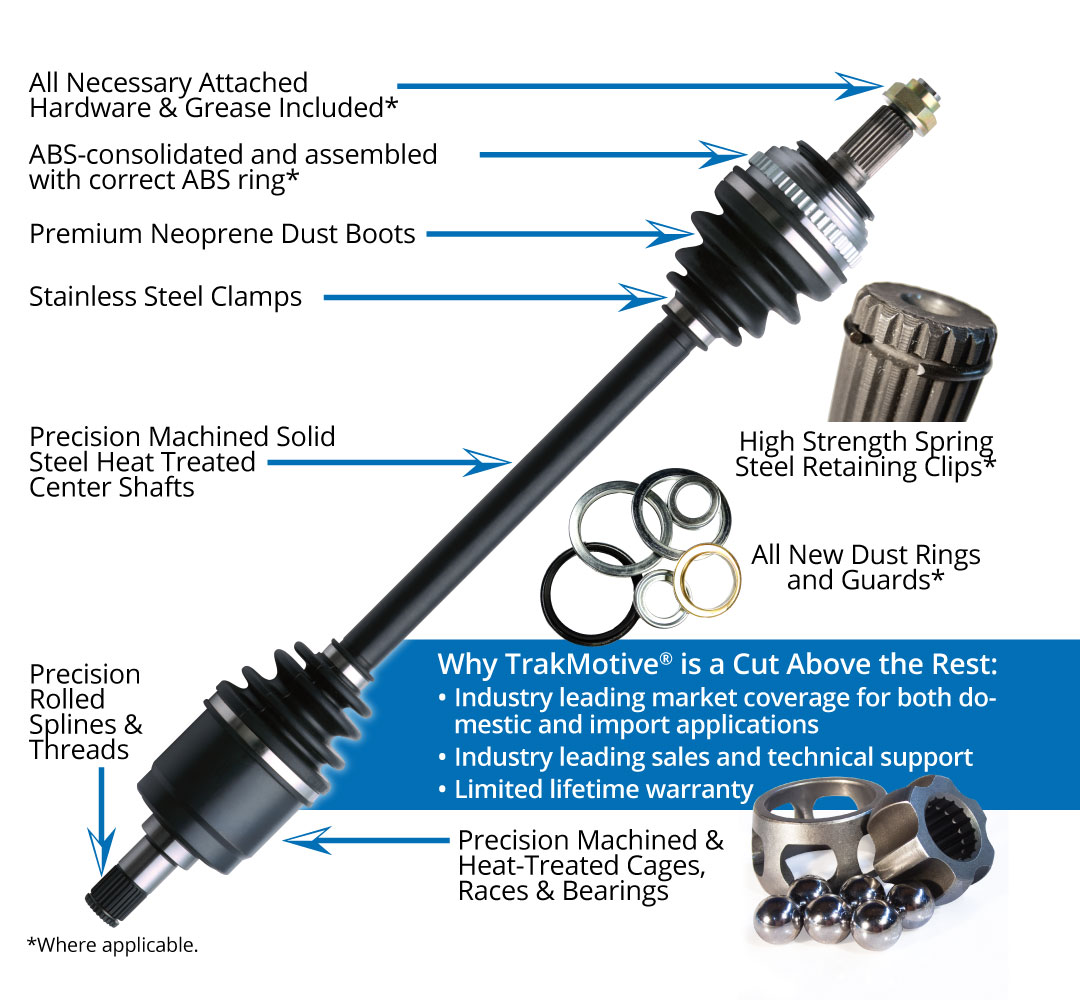

Beyond just length, many extended CV axles also feature:

- Stronger Materials: Often constructed from chromoly steel or other heat-treated alloys, offering superior strength and resistance to torsion and impact compared to OEM mild steel shafts.

- Enhanced Joint Design: Some high-performance extended axles incorporate larger, stronger CV joints with improved internal components, allowing for greater articulation angles and increased load capacity.

- Durable Boots: Redesigned or upgraded boot materials and configurations provide better resistance to tearing and offer improved sealing, even under more demanding conditions.

The primary goal of an extended CV axle is to restore proper drivetrain geometry, thereby extending the lifespan of the axles themselves and protecting other vital components of your truck’s front end.

Benefits of Upgrading to Extended CV Axles

Investing in extended CV axles for your lifted truck offers a multitude of advantages that go beyond just preventing immediate failure:

- Enhanced Durability and Longevity: By correcting the operating angle, extended CV axles significantly reduce stress on the joints and boots, leading to a much longer lifespan compared to stock axles on a lifted truck.

- Improved Reliability: You gain peace of mind knowing your drivetrain is built to handle the demands of your lifted suspension, whether it’s daily driving or aggressive off-road adventures.

- Reduced Wear on Other Components: Proper CV axle angles also alleviate stress on the front differential, wheel bearings, and other suspension components, potentially saving you from costly repairs down the line.

- Smoother Operation: Corrected angles minimize vibrations and binding, contributing to a smoother, quieter ride, especially noticeable in 4WD.

- Prevention of Costly Breakdowns: A failed CV axle can quickly leave you stranded, particularly off-road. Upgrading prevents these inconvenient and often expensive situations.

- Optimized Off-Road Performance: With stronger axles capable of handling higher articulation, your truck can tackle more challenging terrain without fear of drivetrain failure.

Types and Design Considerations

Extended CV axles aren’t a one-size-fits-all solution. They come in various types, each with specific design features catering to different lift heights and performance needs:

- OEM-Style Extended: These axles primarily offer increased length to correct angles for moderate lifts (e.g., 2-4 inches). They often retain similar joint designs and materials to stock, focusing on angle correction rather than significant strength upgrades.

- Heavy-Duty Extended: Designed for more aggressive lifts (4-6+ inches) and demanding use, these axles feature stronger shafts (e.g., chromoly steel), larger and more robust CV joints, and often upgraded boot materials. They are built to withstand higher torque loads and greater articulation.

- Performance/Racing Extended: For extreme off-road applications, long-travel suspension setups, or high-horsepower trucks, these axles represent the pinnacle of strength and articulation. They typically feature significantly oversized joints, highly durable materials, and often include provisions for easy boot replacement or re-greasing.

When considering an extended CV axle, pay attention to:

- Shaft Material: Chromoly steel is a popular choice for its strength-to-weight ratio.

- Joint Size and Design: Larger joints with more robust internal components can handle greater forces and articulation.

- Boot Quality: High-quality, multi-pleat boots made from durable rubber or thermoplastic elastomers (TPE) offer better protection and longevity.

- Serviceability: Some high-end axles are designed to be easily disassembled and serviced, allowing for boot replacement and re-greasing without replacing the entire axle.

Choosing the Right Extended CV Axle

Selecting the correct extended CV axle is crucial for optimal performance and longevity. Here’s what to consider:

- Lift Height: This is the most critical factor. The axle length must precisely match your lift height to effectively correct the angles. Manufacturers will specify the compatible lift range for their axles.

- Vehicle Make, Model, and Year: Axles are vehicle-specific. Ensure perfect compatibility with your truck’s differential and hub splines.

- Intended Use:

- Daily Driver/Light Off-Road: OEM-style extended axles might suffice for moderate lifts.

- Moderate to Heavy Off-Road: Heavy-duty extended axles are recommended for their increased strength and durability.

- Extreme Off-Road/Racing: Performance extended axles are a must for high-stress applications.

- Budget vs. Quality: While extended CV axles can be an investment, skimping on quality can lead to repeated failures and greater overall costs.

- Differential Drop Kits: For many IFS lift kits, a differential drop kit is installed concurrently. This lowers the differential slightly, further reducing the CV axle angles. When choosing extended CV axles, ensure they are compatible with or designed to complement the use of a diff drop if you have one.

- Brand Reputation: Stick with reputable aftermarket brands known for quality and customer support.

Installation Guide (Overview)

While a detailed installation is beyond the scope of this article, understanding the general process can help you decide between DIY and professional installation.

Safety First: Always use jack stands, wheel chocks, and proper personal protective equipment.

Basic Steps:

- Prepare: Loosen lug nuts, lift the truck, secure on jack stands, remove wheels.

- Access: Remove brake caliper and rotor.

- Disassemble: Loosen and remove the axle nut. Separate the upper or lower ball joint (or tie rod end) to allow the spindle to swing out, creating space to remove the axle.

- Remove Old Axle: Carefully tap the axle out of the hub assembly. Then, pry the inner CV joint out of the front differential (some may require a puller).

- Install New Axle: Slide the new extended CV axle into the differential, ensuring it seats fully. Guide the outer splined end through the hub.

- Reassemble: Reattach the ball joint/tie rod, brake components, and finally, torque the axle nut and lug nuts to factory specifications.

Professional Installation: If you’re not comfortable with automotive repairs, have limited tools, or lack experience, professional installation is highly recommended to ensure safety and proper function.

Maintenance and Longevity Tips

Even with extended CV axles, proper maintenance is key to maximizing their lifespan:

- Regular Inspection: Periodically inspect the CV boots for cracks, tears, or grease leaks. Catching a torn boot early can save the entire joint.

- Check for Play: While the truck is on jack stands, try to move the axle shaft up/down and in/out. Excessive play can indicate internal wear.

- Avoid Extreme Angles: While extended axles help, continuously operating at maximum articulation (e.g., full steering lock while heavily articulated off-road) will still accelerate wear. Drive judiciously.

- Address Suspension Issues: Worn ball joints, tie rod ends, or wheel bearings can put additional stress on CV axles. Address these issues promptly.

Practical Advice and Actionable Insights

- Don’t Compromise on Quality: Your CV axles are critical. Investing in high-quality extended axles from a reputable manufacturer will save you money and headaches in the long run.

- Verify Compatibility: Double-check all specifications (lift height, vehicle model, side of installation if applicable) before purchasing.

- Consider a Diff Drop: For many lift kits (especially 4-6+ inches), a differential drop kit works in conjunction with extended CV axles to achieve the best possible angles.

- Post-Installation Check: After installation, drive the truck and listen for any unusual noises. Re-torque the axle nut after a few hundred miles.

- Learn More: For deeper dives into specific products or installation techniques, consult forums, product reviews, and manufacturer guides. Learn more about Extended CV Axles here

Concluding Summary

Lifting your truck dramatically changes its appearance and capability, but it also necessitates careful consideration of drivetrain components like CV axles. Extended CV axles are not merely an upgrade; they are a crucial modification for any lifted IFS truck, restoring proper geometry, enhancing durability, and safeguarding your investment. By understanding the underlying issues, choosing the right extended axles for your application, and performing proper maintenance, you can ensure your lifted truck remains reliable, capable, and ready for any adventure.

Table: Extended CV Axles for Lifted Trucks – Price Guide

| Axle Type | Target Lift Height Range (Inches) | Typical Price Range (Per Axle) | Key Features | Target Use Case |

|---|---|---|---|---|

| OEM-Style Extended | 2 – 4 inches | $150 – $300 | Corrected length, similar materials/joints to OEM, improved boot design | Daily driver, light off-road, budget-conscious, moderate lifts |

| Heavy-Duty Extended | 3 – 6 inches | $300 – $600 | Stronger chromoly shafts, upgraded internal joint components, durable boots | Moderate to aggressive off-road, heavier trucks, more demanding conditions |

| Performance/Race Extended | 4 – 8+ inches (often long travel) | $600 – $1200+ | Oversized joints, high-strength alloys, extreme articulation, serviceable boots | Extreme off-road, rock crawling, desert racing, high-horsepower applications |

Note: Prices are estimates and can vary significantly based on vehicle make/model, brand, specific features, and market fluctuations. Always check current pricing from reputable retailers.

Frequently Asked Questions (FAQ)

Q1: Do I really need extended CV axles for my lifted truck?

A1: For any IFS truck lifted 2 inches or more, extended CV axles are highly recommended. While you can run stock axles, they will be operating at extreme angles, leading to premature wear, boot failure, and potential catastrophic breakdown, especially under off-road conditions. It’s a critical reliability upgrade.

Q2: What’s the difference between extended and heavy-duty CV axles?

A2: "Extended" primarily refers to the increased length to correct angles. "Heavy-duty" refers to the construction materials and joint design, which are often stronger and more robust than OEM. Many extended CV axles are also heavy-duty, offering both increased length and strength.

Q3: Can I just use a differential drop kit instead?

A3: A differential drop kit lowers the front differential to reduce the CV axle angle. It’s an excellent modification that often works in conjunction with extended CV axles for optimal angle correction, especially on 4-6 inch lifts. For higher lifts, a differential drop alone may not be enough to fully correct the angles.

Q4: How do I know what length extended CV axle I need?

A4: The required length is directly related to your truck’s specific lift height and suspension geometry. Always purchase extended CV axles that are explicitly designed and marketed for your truck’s make, model, year, and the exact lift height you have installed. Consult the axle manufacturer’s specifications.

Q5: What are the signs of a failing CV axle?

A5: Common signs include a clicking or popping noise (especially when turning or accelerating), a grinding sound, vibrations (particularly at higher speeds or in 4WD), grease leaking from a torn boot, or excessive play in the axle shaft.

Q6: Is installation difficult?

A6: CV axle replacement is a moderately challenging DIY task requiring specific tools (e.g., torque wrench, large sockets, pry bar, possibly a ball joint separator) and mechanical aptitude. If you’re not comfortable, it’s best to have a qualified mechanic perform the installation to ensure safety and proper function.